If a device is expected to deliver full performance even under changing conditions, such as varying temperatures, control is particularly important. Model-based controllers enable precise and predictive control. Helbling has developed a model-based approach on the basis of a practical case study in order to optimally tailor the algorithm to the respective application. This makes it possible to improve parameters such as performance, stability and efficiency separately or in combination, depending on requirements. Existing systems in particular benefit from these optimizations.

Temperature control with future potential

Precise control is essential in many technical applications: for example, in industrial thermal process control, in hot water systems in household appliances, or in optimizing the indoor climate of buildings. Classic PID controllers, which are the most widely used, usually perform this task reliably, but they reach their limits when faced with dynamic requirements or when there are many control variables that influence each other. They struggle under the influence of variables that cannot be measured directly. This can, for example, be due to the unpredictable entry of people who affect the temperature in a room or the calcification of a household appliance. Helbling experts were tasked by customers with finding a solution for these cases and asked themselves the specific question:

How can we improve the control error using data-based methods?

Helbling's approach: virtual models as a test environment

To answer this question, the teams at Helbling relied on a virtual model that realistically maps the thermal properties of the respective system. This creates an environment in which control algorithms can be efficiently developed and tested without any risk to the hardware.

Helbling created a model of an instantaneous water heater (thick-film heater) as a concrete use case. This system has a low thermal mass and therefore a faster response time. The energy flow is first discretized, i.e., divided into individual sections so that it can be described mathematically. Based on this, the model and the data/sensors to be collected are then defined.

Ultimately, the experts used this method to demonstrate, among other things, that a linear dynamic system can be simulated very accurately using only a simple model such as the 1-layer model. For more complex systems with many variables and not only linear relationships – known as multidimensional systems – various models were used for simulation. These included tree-shaped decision trees and artificial neural networks such as convolutional neural networks (CNN). In both cases, the desired target variables could be predicted from the input data with a high degree of accuracy, i.e., close relationships to the output variables could be shown.

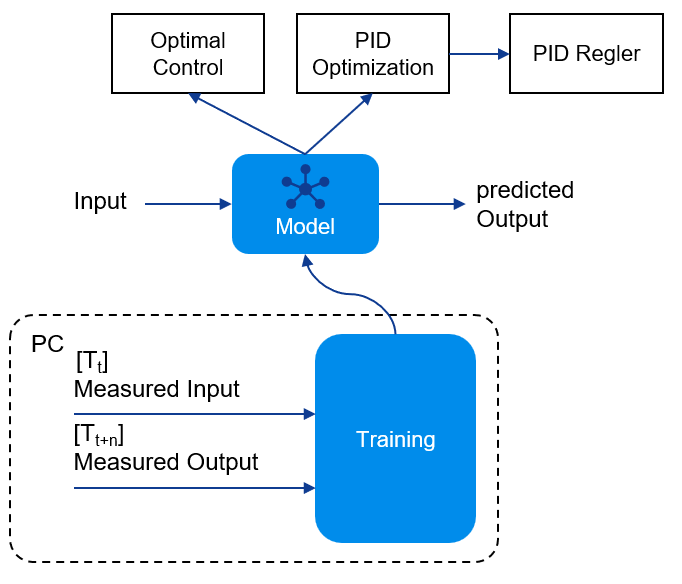

Thanks to this level of accuracy, it was possible to use the model to optimize the control using two different methods (the process is shown in Figure 1).

1. Optimal control: The model is executed directly on the device and the optimal control variable is calculated directly using a grid search.

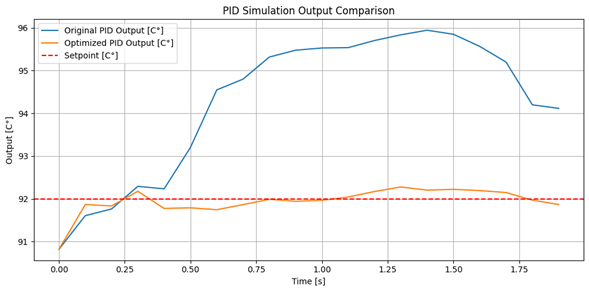

2. PID optimization: The existing PID controller is replicated in software. Then, using a grid search and the model, the PID values are optimized according to the desired behavior. These values can then be transferred to the embedded device and verified. This means that the controller on the device is not changed and the parameter limits can be maintained.

Learning on a small scale: machine learning in embedded systems

The control system developed is based on a lean model with learning capabilities that can be operated entirely on microcontrollers.

Instead of complex networks, Helbling relies on a compact structure with few input values. Examples include data for temperature, power, and flow. The model can respond to component tolerances or temporal changes, such as calcification, or it can be trained. Depending on the controller, this can be retrained directly on the embedded system or in the cloud in a short time.

This highlights the difference between Optimal Control and the PID Optimizer – if the response time is very short, as is the case with an instant heating system, for example, Optimal Control can be too slow because it calculates the global minimum over the entire time window. This can lead to long delays, making the PID controller more suitable due to the fact that it, as usual, is able to calculate the control very quickly.

Summary: Helbling paves the way for fully model predictive control systems

The solution developed by Helbling is a pragmatic answer to the question of how data-driven methods can improve control errors. New developments benefit from this, but the model is particularly well suited to optimizing existing systems in a sustainable manner. It should be understood as a pragmatic intermediate step on the path to fully model predictive control. Even with simple means, the potential of data-supported optimization is clear. Helbling supports and accompanies companies at all times in integrating model-based control into their systems, thereby designing solutions in a future-oriented manner.

Authors: Daniel Stäuble, Lukas Meier

Main Image: Helbling