Technical value and product quality go beyond excellent functionality. Addressing this dimension in a product represents enormous added value. To achieve this, requirements must be analysed in detail, structured, and translated into concrete component specifications. Helbling implements this with methods such as Robust Design, resulting in mechatronic systems that are both convincing and can be manufactured at competitive costs.

Mechatronic systems today must do more than just fulfil their basic function. The primary function of a product, such as moving around in a car or keeping food fresh in the refrigerator, remains crucial. However, this core function alone cannot make a lasting impression on the market.

A typical example: The closing of a door on a vehicle or refrigerator. What sounds technically banal has a major impact on the subjectively perceived quality. A consistent, smooth force distribution and a dull, rich closing sound without rattling convey a high-quality impression to the user. Such impressions are summarized under the term technical value: a key characteristic for successful products that stand out in the market.

Helbling uses development methods such as Robust Design with the goal of developing products with precisely this high level of value for customers from a variety of industries. Project experience is often transferable from one area to another. Helbling experts not only contribute their knowledge from past development work but also combine expertise from various disciplines. The interplay of mechanics, electronics, and software creates solutions that add a new dimension to functionality.

Specifically, Helbling's methodical development work follows a clear and comprehensible plan, which serves as a toolbox.

A. Specify requirements early on and systematically break them down into verifiable, technical specifications for components.

B. Incorporate robustness aspects into the early, creative development phases.

C. Develop clear specifications for individual parts using ISO GPS.

D. Prevent challenging and therefore expensive tolerance requirements early on.

A. Understanding the functions determines the solution

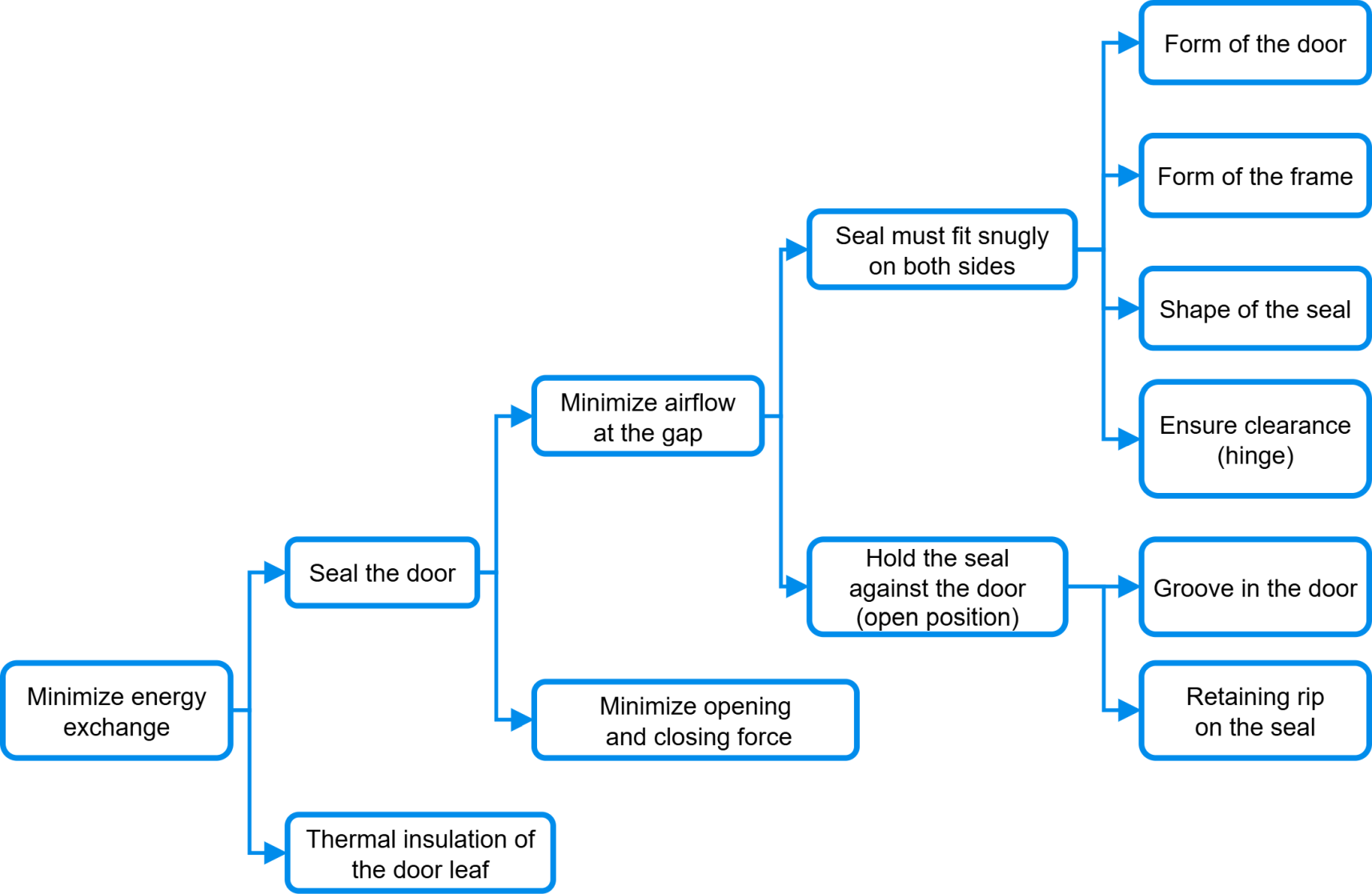

Generally, a door only temporarily closes an opening. In a refrigerator, it keeps food cool, allows access when open, and minimizes energy and air exchange when closed.

The first requirement is therefore still abstract: "Minimize airflow at the gap." This statement is solution-neutral and allows for various technical solutions but is too generic for verification.

In the refrigerator example, a circumferential rubber seal is usually chosen to achieve the function "minimize airflow at the gap." This allows for clear and measurable requirements to be derived for the affected components: door leaf, frame, hinge/lock, and seal.

This is precisely where methodical development work comes in: Requirements must be specified and systematically broken down into verifiable, technical specifications at the component level.

The next step involves the transition from the neutral formulation to the concrete technical solution. A soft seal allows for greater variation in the gap size when closed. If the seal is compressed too little, there is a risk of excessive air exchange. Excessive compression creates an excessive closing force and thus reduces technical value.

One possible solution can be achieved through precise tolerances for the respective components, such as flatness requirements for the door leaf and frame. Furthermore, the hinges must guide the door as parallel to the frame as possible, regardless of the number of beverage bottles on the door shelves. These precise tolerances typically lead to expensive manufacturing processes, complex quality controls, and thus expensive components.

B. Robust Design paves the way for robust alternatives

If the Robust Design perspective is incorporated into the early, creative development phases, solutions are often found that are implicitly insensitive to variations. The subsequent verification of such concepts is usually also significantly more efficient, since, for example, no boundary samples are required.

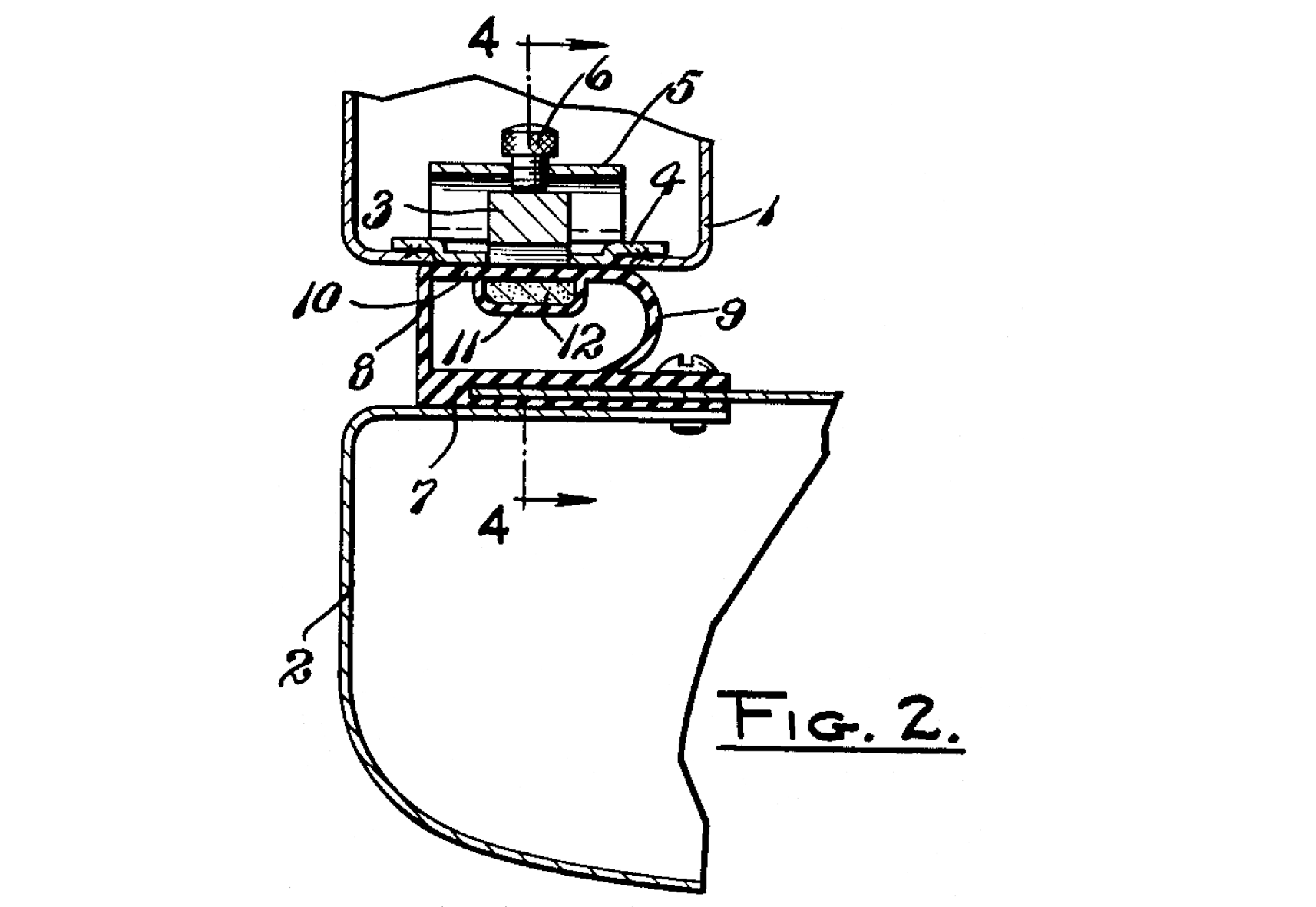

lmage: US-Patent 2659114 von 1950

A much more elegant approach in this regard is the use of a magnetic strip within the seal. When closed, this pulls the seal against the frame, allowing for more generous tolerances and more cost-effective components without compromising on function or quality. The magnetic strip makes the gap less susceptible to variation. This approach is an excellent example of how robust design helps develop high-quality products that don't have to be expensive.

C. Standardized specifications simplify the process

Thanks to the so-called Geometric Product Specification (ISO GPS for short), the necessary requirements, such as flatness, can ultimately be recorded on individual part drawings using a standardized language. Subsequently, specialists from development, production, and quality assurance can understand and implement these requirements consistently. The required specifications arise from the functional requirements, which relate to higher-level requirements.

D. Set tolerances as small as necessary and as large as possible

Tolerances are often based on gut feeling combined with significant margins. This approach results in higher manufacturing costs and can hardly be justified if the specifications are not met. Thanks to Robust Design, products also function with more generous tolerances, which are determined by Helbling experts directly based on the requirements.

Summary: A precise analysis of requirements paves the way for robust solutions

The path from the idea to the finished product involves many steps and requires the coordination of a whole series of components and interfaces. This is especially true in cases where, in addition to strictly functional requirements, those relating to technical value must also be met. Helbling can draw on many years of experience and a tried-and-tested toolbox to master this complexity, while keeping an eye on the budget and avoiding development delays.

Have you ever tested the seal on your own refrigerator with a magnet? Robust Design is that easy to experience.

Author: Martin Ziegler

Main Image: Helbling