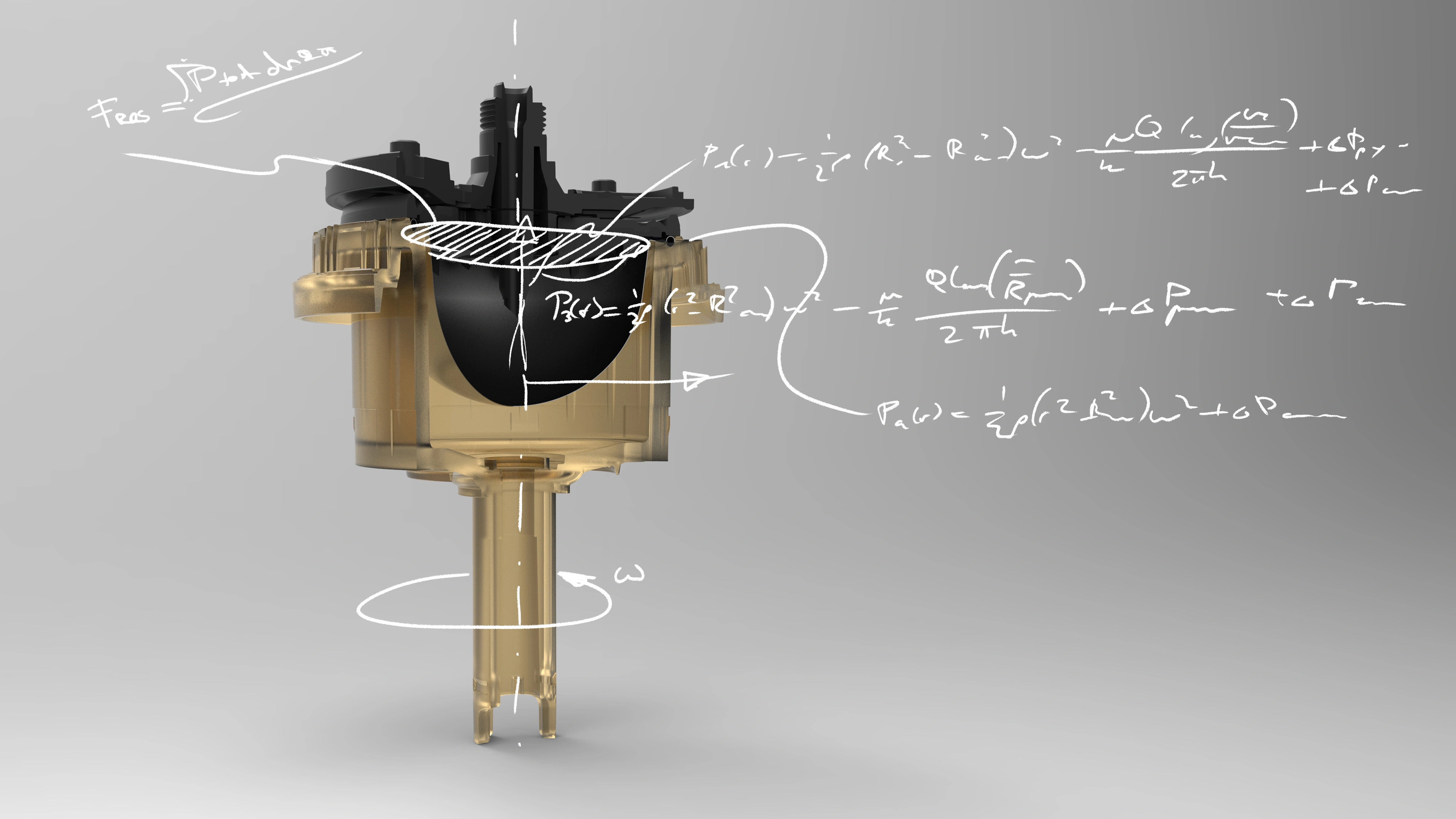

True to the expression "The proof of the pudding is in the eating", in many cases it is efficient to map solution approaches in simplified principle tests using functional models. This provides important insights for the further course of development. Such principle tests are also recommended for testing ergonomic aspects of the use of a product as well as other factors of the user experience (UX) such as intuitive handling, haptics, and aesthetics.

We know how to design and realize such functional models and test setups with the indicated level of abstraction and test them in our own laboratories or via field tests in the end user environment. When it comes to assessing UX aspects, we always involve the customer or designated user groups.

Since we work with rapid prototyping methods, in-house and with specialized suppliers, we are able to realize such tests in a very short time.