Industries

December 2021

Sustainability has become an urgent issue for all sectors of the economy. As a leading engineering and consulting firm, Helbling plays a significant role by helping its business partners to succeed with their transformation towards sustainability and by bringing future-proof solutions. How can such solutions be designed? Helbing uses a holistic approach based on life-cycle thinking and leveraging a well-established, multidisciplinary structure.

In his opening speech at the COP26 climate conference in Glasgow a couple of weeks ago, Secretary-General of the United Nations António Guterres said: “If commitments fall short at the end of this COP, countries must revisit their national climate plans and policies – not every five years (but) every year and every moment.” There can no longer be any doubt as to whether drastic changes will happen in all sectors of the economy. Those who adapt fastest to sustainability-related pressures – whether from new regulations, supply shortages, investor requirements, or consumer expectations – will obviously have a competitive advantage.

For a few years now, interest and demand from clients have been constantly growing in this field. In fact, product and system developers like Helbling have a major role to play. Design and concept choices have an impact on the environmental footprint of the product during its whole life cycle – from extraction of raw materials and production processes to the use phase and end of life.

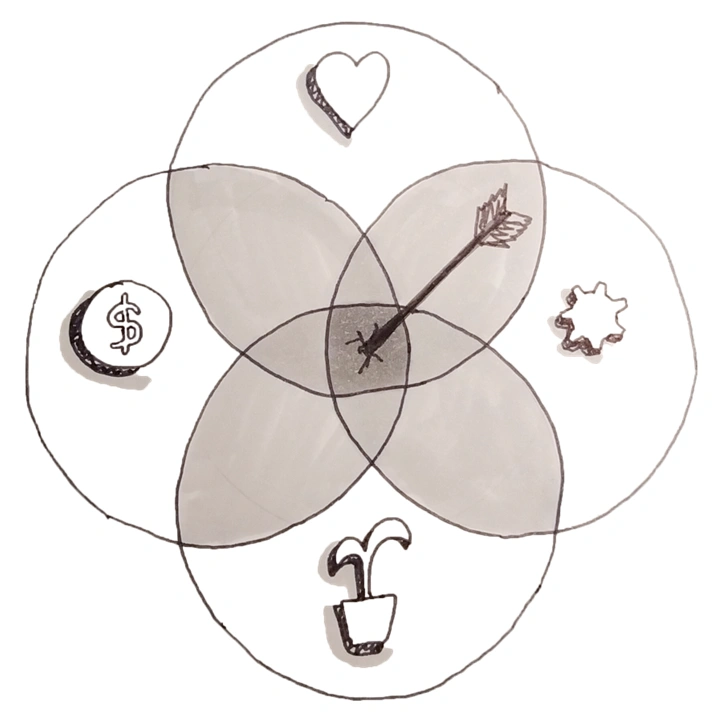

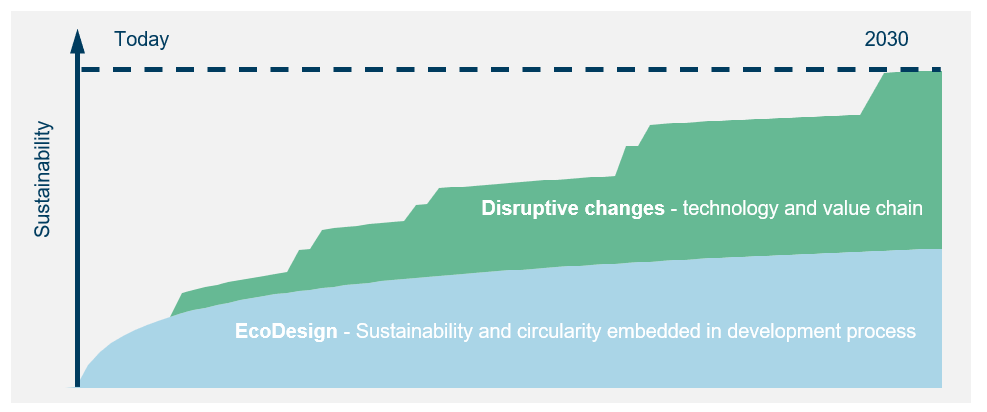

The challenge of making products and systems used in our daily lives more sustainable must be tackled on two equally important fronts (see Figure 1): (1) innovations and disruptive changes in technologies and value chains that can support sustainability targets; (2) integration of sustainability aspects along the product development process. No ambitious sustainability goals can be achieved without considering these two elements.

Leveraging the sustainability benefits and understanding the risks of technological and value chain innovations are key

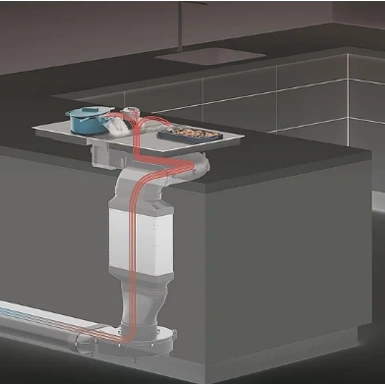

Sustainability innovations have gained significant momentum at the moment, whether materials with a lower environmental impact, new recycling technologies, more energy-efficient technologies, or more circular value chains. There are also a number of technologies not explicitly labeled as “green” that can be tapped into, for example AI being used in the building sector for energy efficiency optimization. Using innovations and making disruptive changes does not come without challenges. Risks must be well understood and adequately addressed by relying on strong scientific and engineering competencies to compensate for the lack of (field) experience inherent in any innovations. For example, over recent years Helbling Technik has designed a water heater using thick-film technology that enables a decrease in electricity consumption of more than 25% compared with conventional water heaters in typical applications. Considering the whole life cycle of such heaters and the typical lifetime, this represents a carbon footprint reduction of about 50 kg of CO2eq per item.

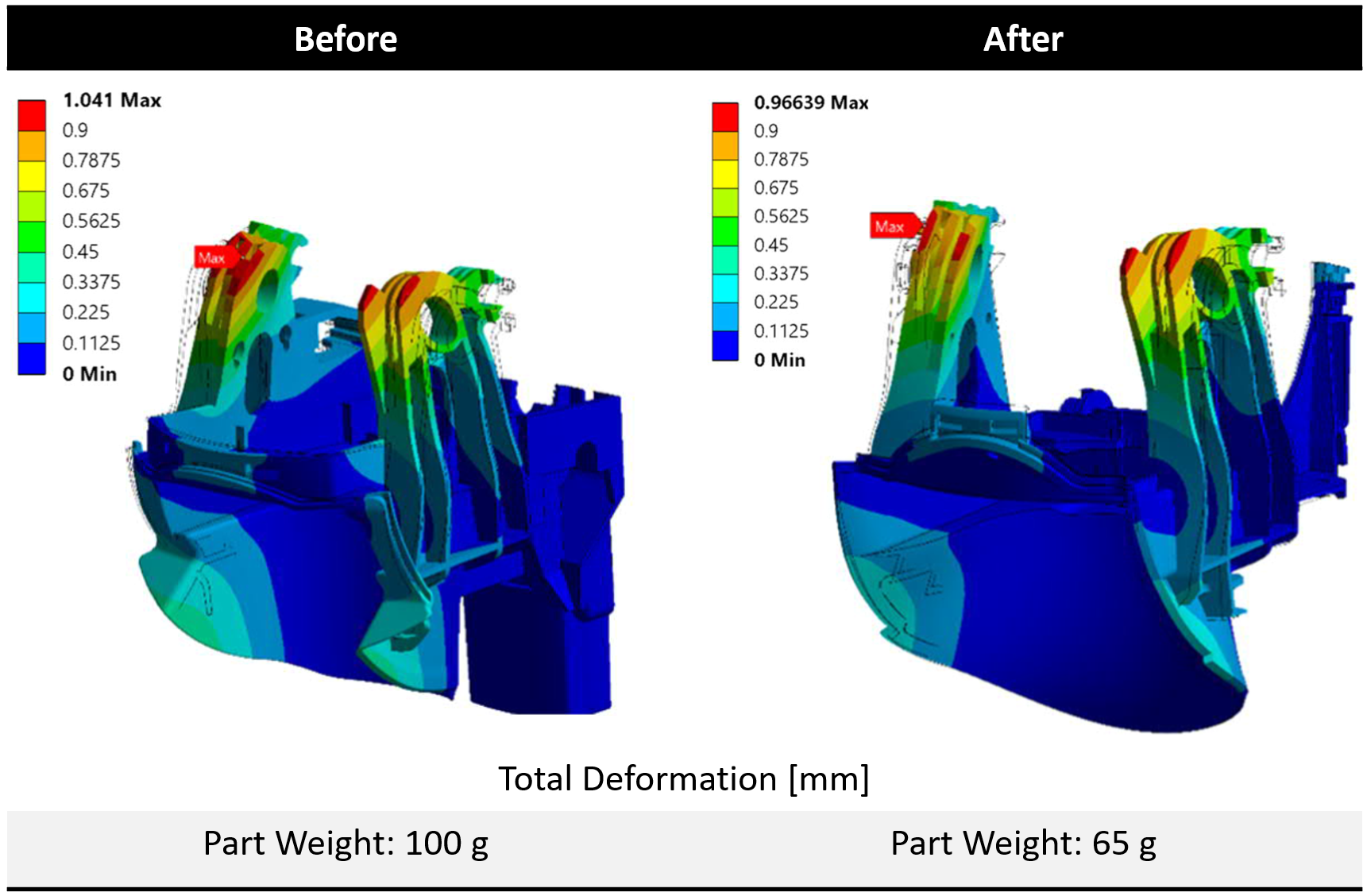

Integrating sustainability aspects into the development process (EcoDesign) is important in order to fully take advantage of available solutions.

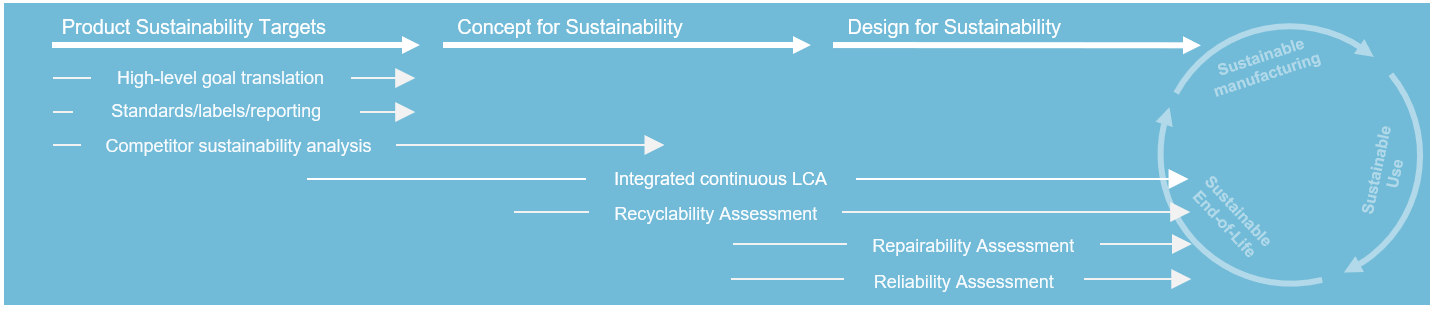

It would be naïve to hope that a few technology breakthroughs alone would solve all sustainability challenges. Moreover, it would mean that many opportunities are missed. Life cycle assessment (LCA) tools and databases, together with state-of-the-art engineering methods and tools, can be used very effectively to optimize product sustainability (see Figure 2).

Using tools to compute mechanical stress and deformation (such as finite element analysis) may help designers to reduce the amount of material used for a part (this is called topology optimization) or to select a plastic with a lower environmental footprint (see the fact box at the bottom). Helbling has supported Nestlé with its sustainability targets in various concrete ways throughout their long-standing partnership. For example, it is estimated that with topology optimization, the total weight of a critical part (plastic chassis) of the Nestlé coffee machine NDG Genio S could be reduced by approximately 35% (see Figure 3).

Another excellent example is the Nespresso U machine, which contains a very high percentage of post-consumer recycled (PCR) plastic (see Figure 4). In total, 70% of the plastic that does not come into contact with the beverage is PCR material. Achieving such high levels of recycled content does not come without design challenges.

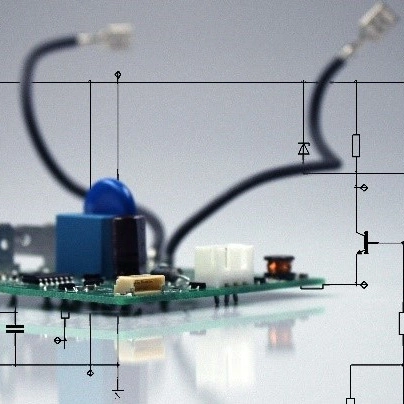

On the electronics side, massive improvements have been made to standby power. Certainly, extra effort was needed during development to investigate different concepts for the power supply unit and filters and to evaluate them with regard to their energy efficiency. However, this extra effort certainly paid off in terms of CO2 savings. By designing a dedicated, separate power supply, the standby consumption of the Nespresso Inissia machine was reduced to 11 mW (see Figure 5). In comparison, a power supply based on standard components consumes nearly ten times more electricity in standby mode.

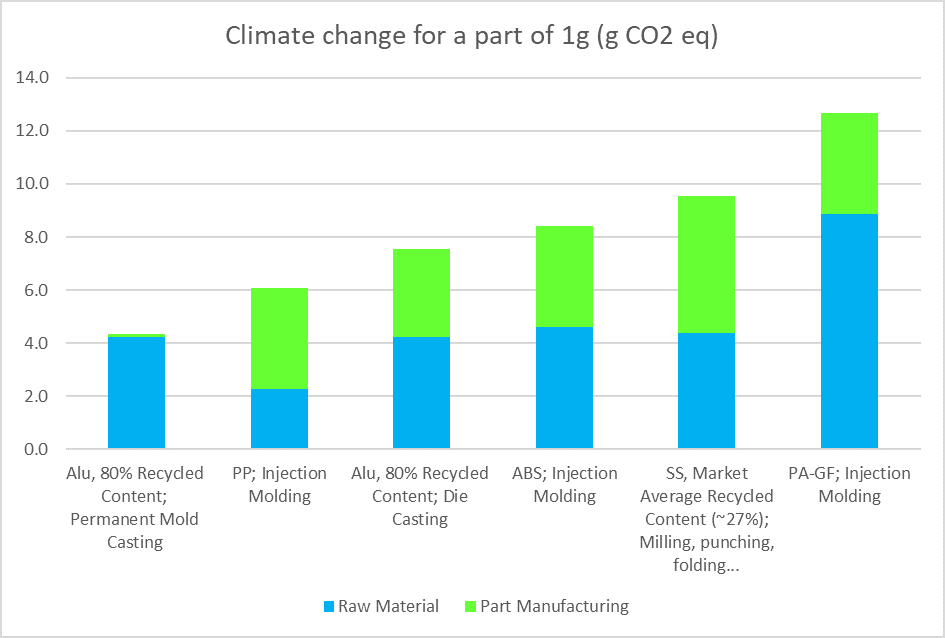

Also, during the final design phase, design for manufacturing and assembly (DFMA) tools can be used to optimize energy consumption per part for injection molding. For small plastic parts (<10 g), CO2eq emissions due to manufacturing can even exceed those related to raw materials.

One way of increasing product sustainability that is often mentioned is extending the product lifetime. Using a reliability modeling and prediction tool can be very useful for this to identify reliability improvement measures that really pay off and to avoid compromising economic viability.

Finally, to complement LCA, other insightful analyses for the evaluation of a design with regard to the circular economy include repairability assessments, recyclability assessments, and material circularity index evaluations.

Software is another important tool for reaching sustainability goals

As a software provider, Helbling also considers the topic of sustainability in the life cycle of software products that it designs and delivers to its customers. Needless to say, software undergoes the same considerations as hardware when it comes to sustainable development. It is very important to consider life cycle topics early on in the architecture and design phase as with other quality attributes like performance. Helbling calls this architectural style “sustainability by design”. Sustainability by design seeks to use energy-minimizing services.

Most enterprise applications and software ecosystems nowadays are built in cloud environments. Cloud providers can reduce resource waste by assigning server resources to workloads only when needed. This means that they can share the server resources across all their customers.

Another important topic is to quantify and ultimately minimize the environmental footprint in a cloud environment. This involves tracking and reducing carbon emissions related to cloud service usage, increasing emission transparency (e.g., by using the Microsoft Sustainability Calculator), and simplifying environmental reporting.

Once the services that use the least energy have been identified, an architecture can start to be built based on these services.

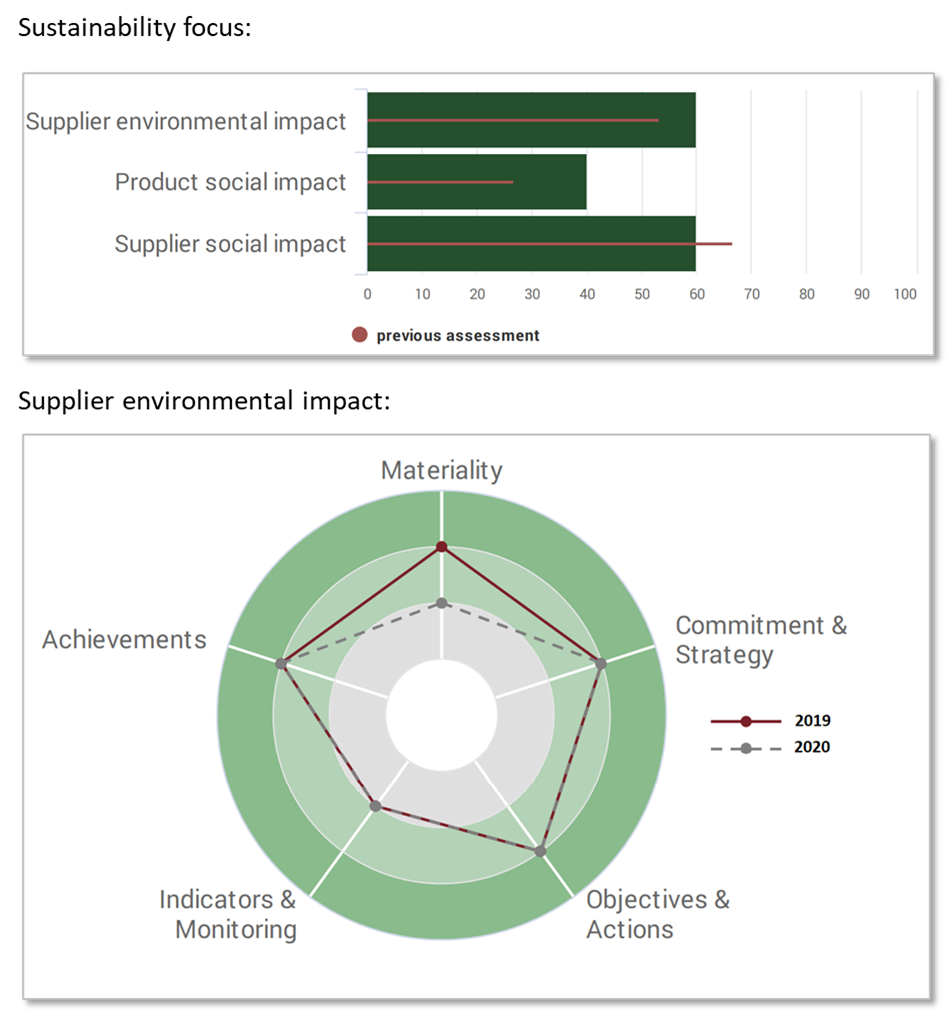

At the other end, Helbling is also supporting companies in their endeavors to become more sustainable. Helbling has created an online platform for BHP – Brugger und Partner AG that can perform and document sustainability analyses on companies in a fund portfolio and simplify subsequent investor dialogs with these companies (see Figure 6).

Summary: Helbling goes beyond the low-hanging fruit to create more sustainable solutions.

In most cases, Helbling must go beyond the low-hanging fruit to acceptably reduce the environmental footprint of the products it designs. Sustainability improvements can come from disruptive changes (technological or value chain) or from the design approach, which should be holistic and integrate sustainability aspects as early as possible. Leveraging these two pillars is the key to achieving ambitious sustainability goals for the systems that Helbling develops.