Technology

Process Technologies

From first ideas to real-world application – we develop and implement scalable processes for a sustainable future.

We systematically design, develop, control, and integrate complex chemical, physical, and biological processes using an interdisciplinary approach, always with the focus on implementation. Whether an early feasibility study or a production-ready solution – we support our customers throughout the entire development process and make the leap from lab concepts to real-world applications. We create systems that are sustainable, scalable, and economically viable. With our in-depth technical expertise and a strong focus on feasibility, we deliver solutions that not only work on paper but are also reliable in operation.

Process Design

We understand how processes work – and how to design them to be economical and sustainable.

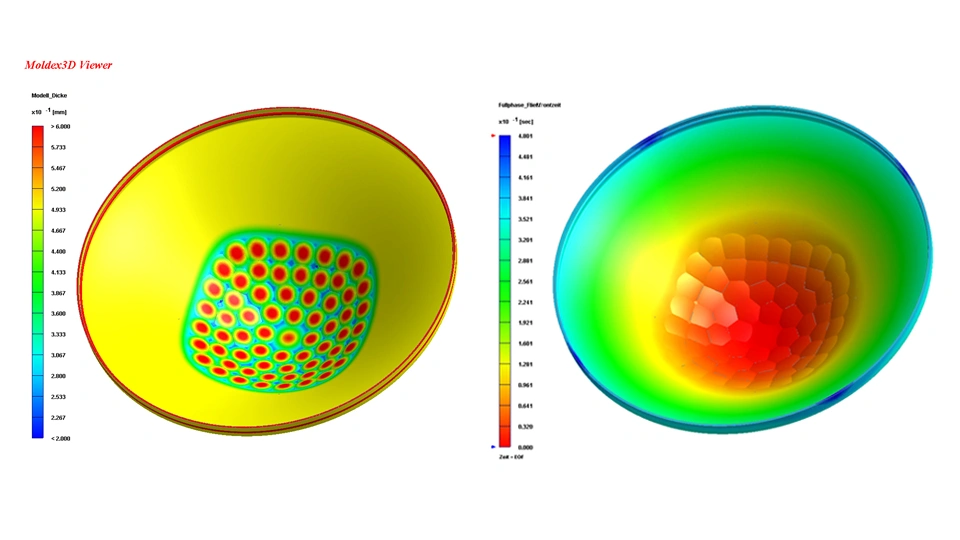

From fundamentals and first principles in physics, chemistry, thermodynamics, fluid dynamics, and biological systems, we develop robust, scalable, and efficient processes. Simulation, process design, and data-driven methods such as e.g. design of experiments (DoE) help us to identify optimal operating windows and guide our development.

Our focus areas:

- Process-engineering design and analysis

- Simulation & design using tools such as Ansys, COMSOL, Simulink & MATLAB, and SolidWorks

- Focus on cost-effectiveness and sustainability

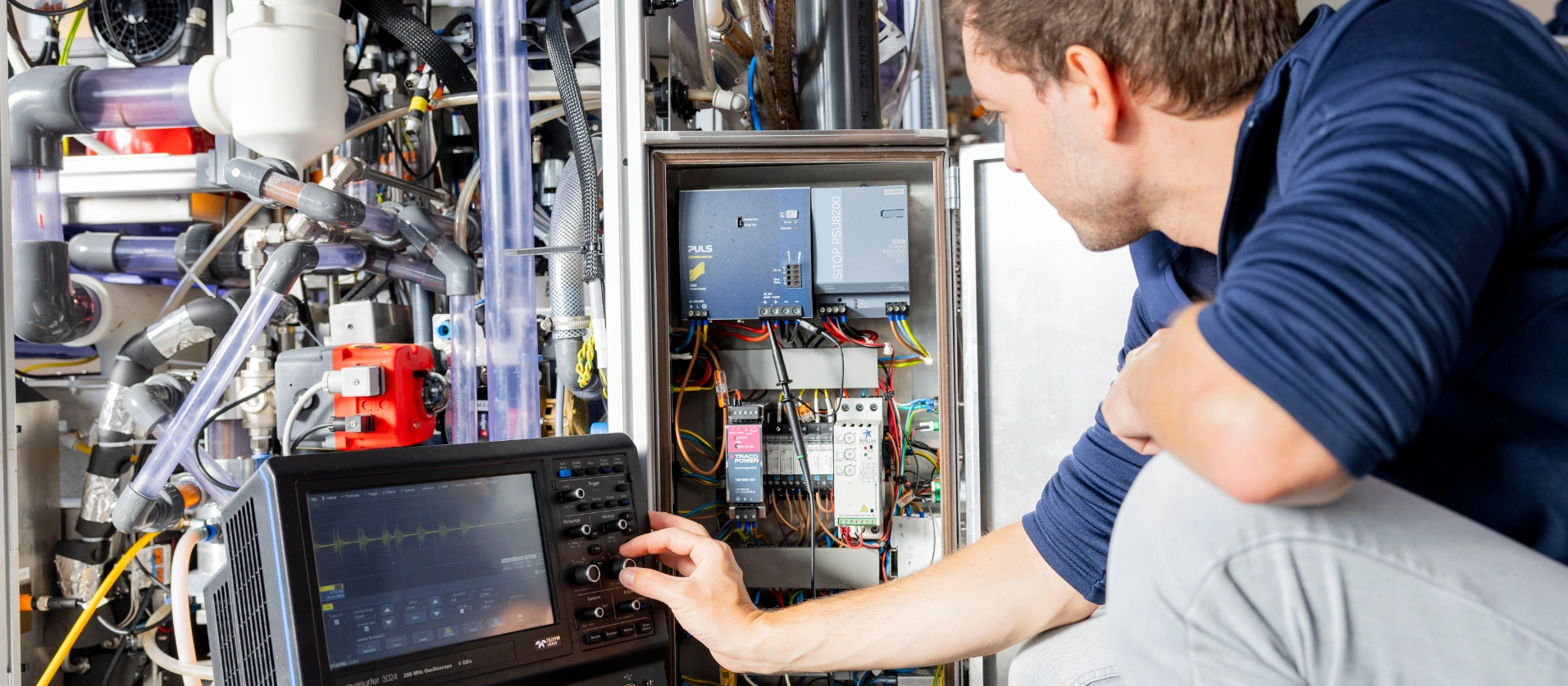

Process Integration

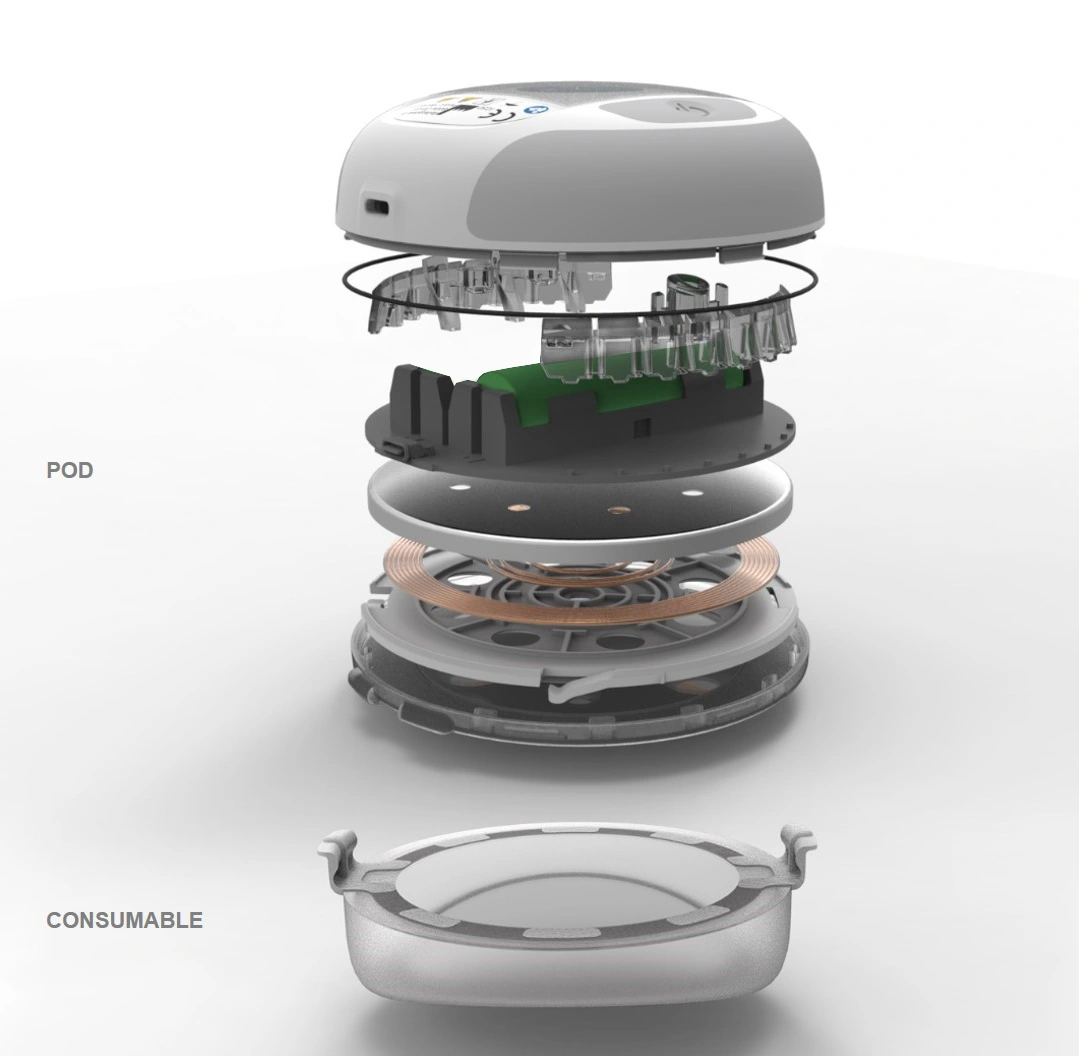

From proof-of-concept test rigs to production-ready equipment – we turn individual parts into coherent systems.

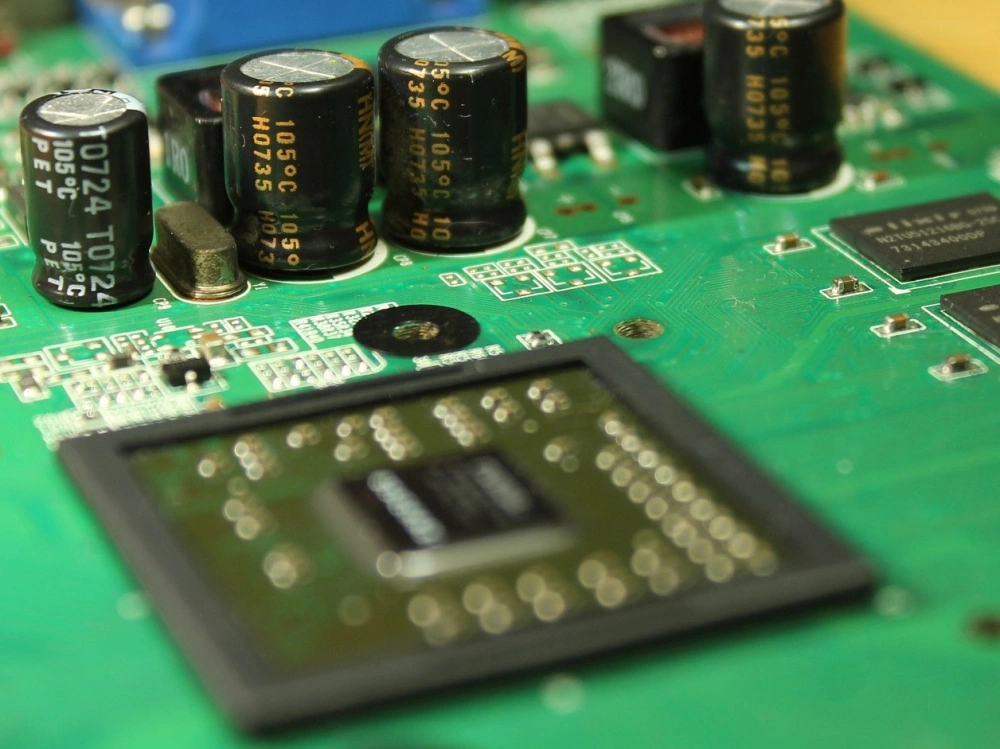

With our technical understanding of systems-engineering, a methodical approach, and high adaptability, we integrate processes in demanding environments. We combine materials, sensors & actors, control systems, and environmental conditions to create functional systems – always with efficiency, quality, and repeatability in mind.

We work in a structured way, think in systems, and remain open to new insights and pragmatic solutions.

Process Control

Robust processes need precise control – we develop intelligent systems for monitoring and control.

By combining sensors, actuators, and data analytics, we ensure stable and reproducible processes – even under difficult and changing conditions. Our expertise is particularly pronounced in gas sensing, the treatment of liquids and the control of physical processes.

Typical applications:

- Control of physical and chemical reactions

- Use of modern gas and liquid-phase sensors

- Inline measurements and real-time data analysis

Processes can only be improved and optimized if they are understood – we build the foundation for that.

Infrastructure

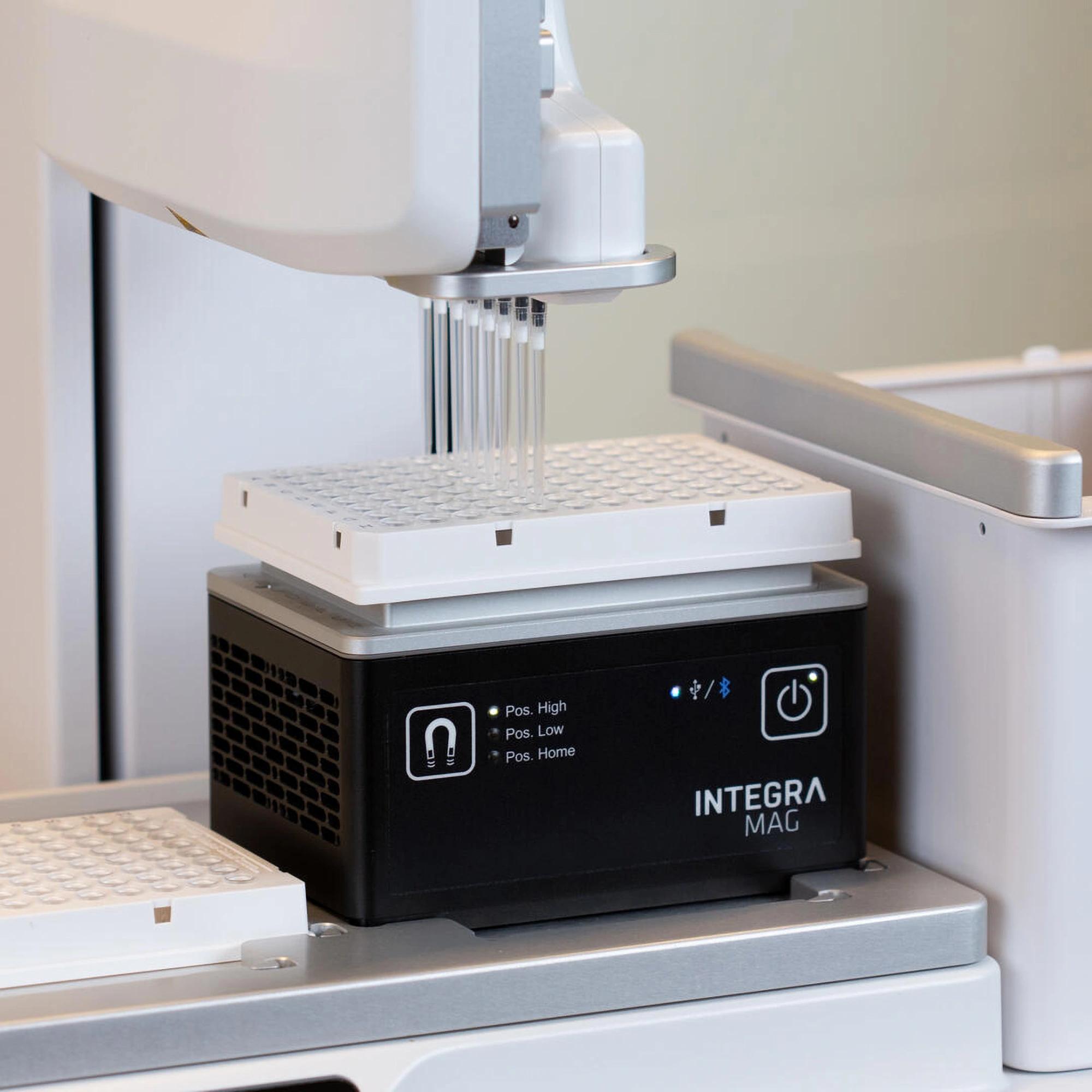

Development needs space, speed – and the right tools.

With our versatile infrastructure, we can flexibly plan, design, and evaluate processes by experiments in-house. This enables rapid iterations, reliable insights, and short development cycles.

Our facilities and equipment:

- Chemistry laboratory for synthesis and analytics

- Test facilities incl. measurement chambers, particle measuring devices, dust generators, and gas

- measurement technology

- Gas-phase laboratory with sensors and optical spectrometers for concentration measurements

- Liquid-phase lab for measuring pH, conductivity, membrane performance and other key parameters

- Workshop for assembly, prototyping and rapid modifications

- CAD & simulation tools

- Data analysis & automation tools

Our infrastructure enables us to quickly implement, validate and continuously improve ideas – hands-on and goal oriented.