In globally connected supply chains, logistics processes play a central role. They are difficult to optimize, but if this is achieved they can create substantial efficiency advantages due to the key position of logistics. Radio-frequency identification (RFID) allows a decisive increase in efficiency here with regard to rising demands for sustainability, security, and speed. RFID forms the foundation for flexible and future-ready process digitization. Helbling’s experts contribute knowledge and experience so that planning and implementation obstacles can be overcome even in the event of complex integration.

The growing complexity of global supply chains demands technological solutions in logistics that speed up processes, reduce errors, and cut costs. One way of achieving this is radio-frequency identification (RFID). This technology permits a vital step toward the digitization of logistics process by identifying and recording objects in real time, automatically, contactlessly, and flexibly.

Unlike barcodes, which require a line of sight, RFID allows simultaneous reading of multiple items without visual alignment. The contents of crates or large storage bins can be identified without the need to open them. This means that warehouse processes can be automated, booking errors are minimized, and accurate inventory management is ensured both at warehouses and in the field. RFID helps companies to create logistics transparency and continuously optimize operational workflows. However, while the material costs are low, implementation can be complex. Helbling supports companies with deciding the extent to which RFID is suitable for a specific application as well as with planning and implementation.

Overview of RFID Technology

An RFID system consists of an RFID tag, a reader, and an IT-supported data processing unit. The tag, containing a unique identifier, is attached to an object and read wirelessly by a reader. The data is transmitted in real time to a central database or ERP system.

There are passive tags (no power source) and active tags (with a battery). The choice of which to use depends on factors such as range requirements. Near field communication is also used. This is a short-range communication technology based on RFID that is particularly suited to product verification or customer-facing smartphone applications.

RFID in Practical Use

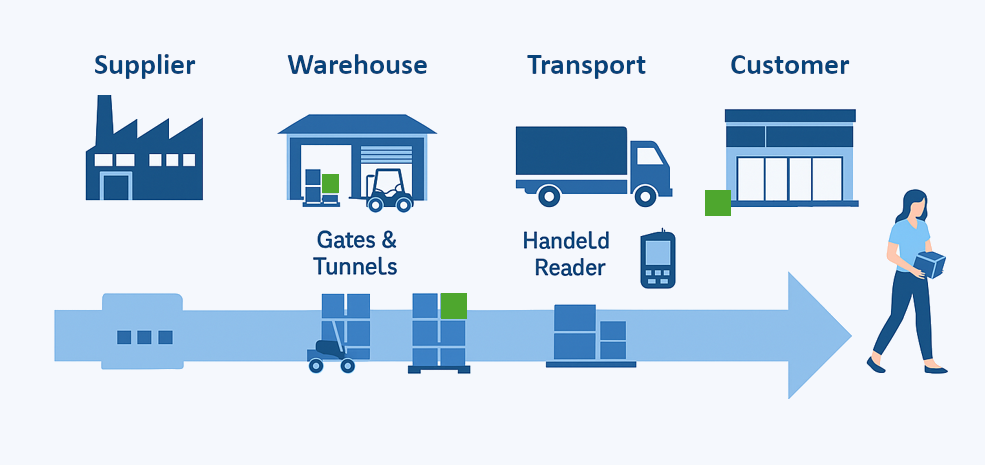

A typical RFID-based logistics process begins with tagging items in the warehouse. Each product or device is equipped with an RFID tag containing a unique ID. During packing or loading, a fixed or mobile reader automatically captures all tags. The data is transmitted to the central warehouse management system (WMS or ERP), which checks the shipment for completeness and accuracy, in real time.

When leaving the warehouse, goods pass through an RFID gate that scans all accompanying items again. This ensures no unregistered items are delivered and none are missing. The delivery process can be linked to RFID data with GPS tracking, allowing the delivery status and transport risks to be monitored. For returns, especially in rental scenarios, the same RFID system is used to verify the completeness and condition of the items sent back. Items with an RFID tag can be clearly identified. This is particularly valuable in rental applications to determine the added value, use and thus the need for maintenance.

When Is RFID the Right Choice?

For projects involving the introduction of RFID, Helbling experts first analyze whether the technology’s full potential can be utilized. While hardware costs are relatively low, hardware and process integration require time and expertise. The initial setup can be complex due to system interface requirements. Over time, as manual item entry and errors are reduced, RFID’s benefits become clear. This is especially recognizable for items that only need to be tagged once and repeatedly follow the same processes, as in the case of rental equipment.

Use in the Rental Sector

RFID tracking is especially worthwhile in industries working with valuable products, under time pressure or with need for a great deal of space. A good example is the rental of costly equipment such as machines or expensive, specialized tools. In such cases, delayed or incomplete deliveries result in high resulting costs. In these instances, RFID enables precise shipment tracking, clear item assignment, and automated status updates. This not only reduces losses but also speeds up damage resolution and builds customer trust. Furthermore, clear item identification lays the foundation for smart, predictive material use and maintenance.

In the rental business, traceability is essential. Delays, incomplete deliveries, or lost items can lead to high secondary costs and dissatisfied customers. RFID captures all items from dispatch to return. Damage or missing parts can be clearly identified. This transparency ensures smoother operations and reduces billing effort.

Use in the Food and Pharmaceutical Industries

RFID allows clear labeling of all production units in the food and pharmaceutical sectors. Faulty products can be quickly traced and removed from circulation without the cost of wide-scale recalls.

In retail, RFID adds value, especially through NFC. Clothing or alcoholic beverages can be equipped with NFC tags allowing customers to verify product authenticity, protecting against counterfeiting and boosting brand trust. These digital tags can also include information such as care instructions and origin, supporting both quality assurance and customer loyalty. Additionally, material can be saved and staff deployed more efficiently.

RFID Supports Sustainability Goals

RFID is particularly attractive to companies focused on sustainability. An optimized RFID process not only improves supply chain transparency and response times but also contributes measurably to sustainability. More precise inventory control reduces overproduction and safety stock, in turn lowering material usage and storage space needs. Errors or double entries are avoided, eliminating unnecessary transport and returns. At the same time, RFID lays the foundation for dynamic, demand-driven logistics, allowing for more efficient transport bundling and fewer empty trips. All of this saves costs and directly contributes to a decrease in emissions.

Summary: Traceability Is a Key Aspect of RFID

RFID delivers measurable added value across various industries, including in terms of sustainability as a result of higher quality, reduced losses, and more accurate data. The extent of its benefit depends on how important traceability is in the respective use case. This becomes particularly evident in rental and leasing applications or the food and pharmaceutical sectors. Helbling supports companies in optimizing their logistics with the right technologies.

Authors: Teodora Nechita, Adrian Roth

Main Image: Generated by ChatGPT 4.0