June 2022

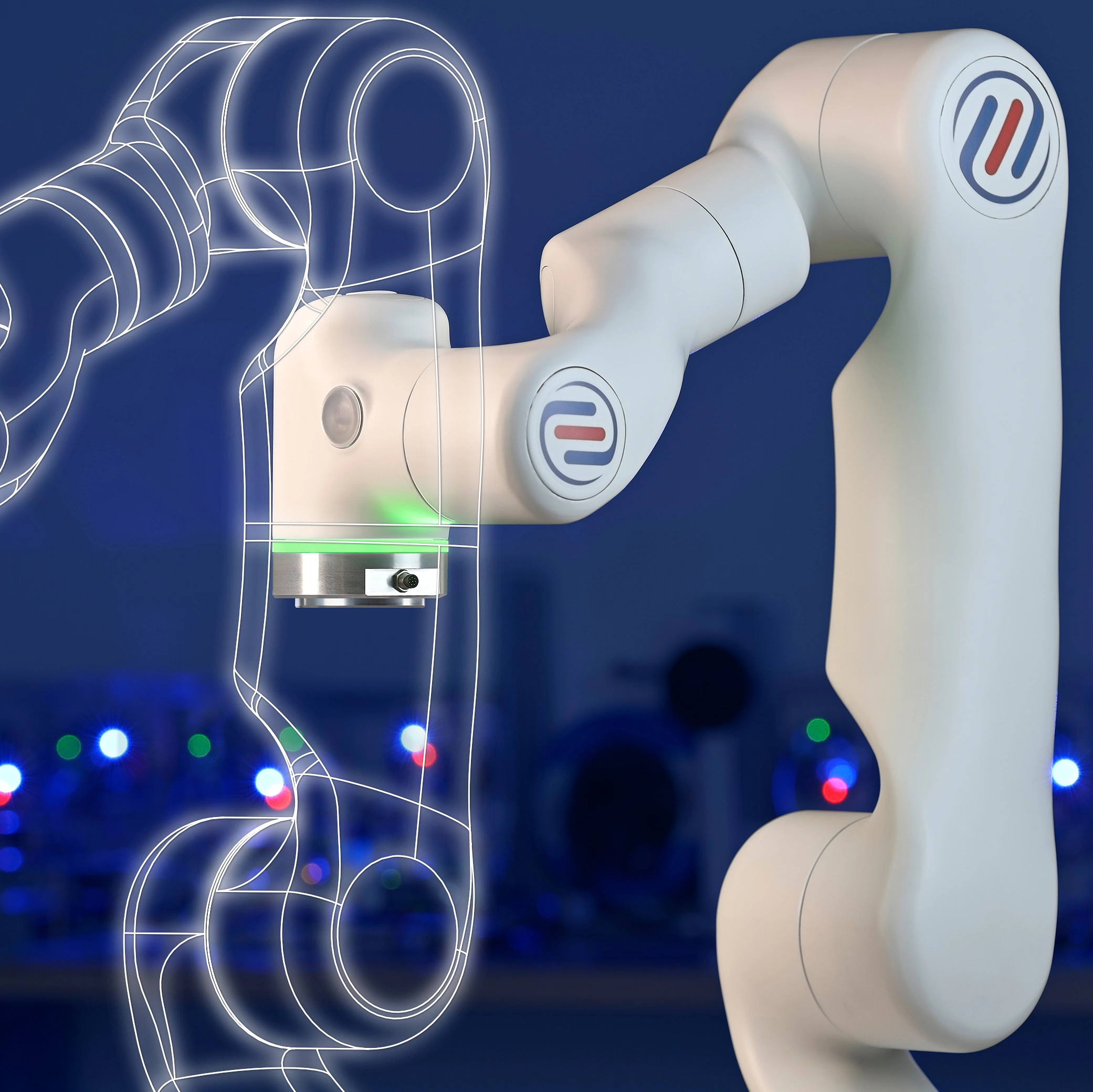

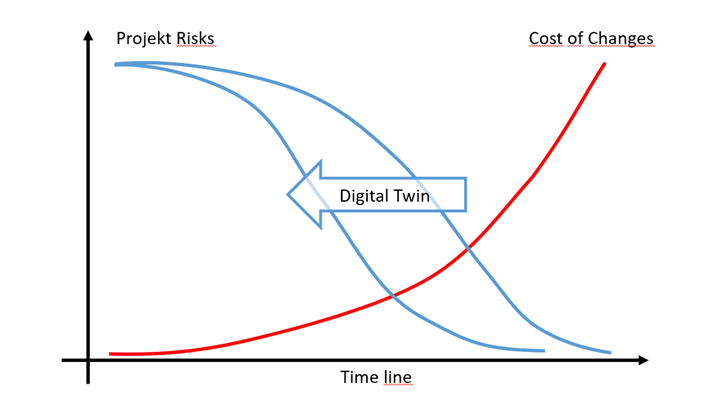

Digital tools have become indispensable in product development. The community is using digital twins to address the question. This aims to identify the effects resulting from the interaction of various physical active principles even before a prototype is implemented, optimizing the product and mitigating the corresponding risks virtually. Helbling achieves remarkable results through the use of digital twins in the development of mechatronic systems.

In parallel with the increasing availability of processing power and computers, the 1960s saw the emergence of the first computer programs to support product development. The most prominent of these are CAD (computer aided design) systems, which had largely replaced drawing boards in design offices by the 1990s.

Other applications also evolved in step with the digitalization of product development, for example: FEM (finite element method) programs for strength calculations and CFD (computational fluid dynamics) programs for the numerical simulation of flows.

With the remarkable collapse in the costs of computing power and storage space, the possibilities of computer-aided development methods have increased steadily to date; numerical models have become more complex, virtual representations more detailed, and it is now possible to link different physical phenomena (multiphysics simulation).

Needless to say, digital development methods are also used at Helbling. While numerical and analog approaches still complement each other in testing and verification, development work in terms of product definition (CAD) has been exclusively digital for decades.

The interdisciplinary bridge in the virtual environment

The term “digital twin” has been established for some time now in connection with computer-aided development. The basic idea behind this is to digitally map a product in its entirety in terms of its physical behavior in order to identify a large number of questions arising from interdisciplinarity, which until now could only be answered with prototype tests. This approach enables iterative optimization at an early stage of development.

Even with the use of powerful computers, the digital representation of a complex system still requires abstraction. This is especially true when coupled, transient, or non-linear processes must be mapped.

In reality, the buzzword “digital twin” is often somewhat overused. At times, even a complete representation of the mechanical structure of a product in a CAD system is advertised as a digital twin, although “digital half-brother” would be more accurate. One fundamental characteristic of a true digital twin is that it serves as a platform for various stakeholders and, in particular, virtualizes interdisciplinary bridging.

Helbling relies on digital twins for the development of mechatronic systems

Efficient interdisciplinary collaboration within a network of specialists is what sets Helbling apart from the rest. It is therefore natural for Helbling to address in the course of development process digitalization how this interdisciplinarity can also be implemented in the digital world. As part of an internal development project involving several client projects, Helbling has advanced the topic of digital twins in the field of mechatronic system development.

The central elements of a mechatronic system are the mechanics, actuators, sensors, electronics (hardware), firmware, and software. This means that the system is fundamentally interdisciplinary. In a traditional development flow, these elements are created in parallel and can only be tested together for the first time when the physical system is put into operation. Often, each discipline uses its own models, terminologies, and tools, making alignment at interfaces lossy and thus not very efficient. This usually comes to light when, during commissioning, logical processes have to be rechecked and changed. Only then is it possible to address the actual focus of commissioning a new development, namely testing and optimization of processes.

This unsatisfactory situation can be relieved if a common platform for all disciplines involved is created early in the process. While process and machine engineers define the physical behavior of the machine and product and develop the mechanical design, control specialists can program processes on the same model and, for example, identify where additional sensors may be needed for monitoring. Operation (“the user experience”) can also be designed and tested at an early stage.

This vision becomes possible when, even early on during concept study stages, the CAD model is enhanced by mechatronic element mechanics and provided with control interfaces, which are also virtual initially. Multiphysics simulators like those used in game engines are applied to virtually depict physical components. Many well-known manufacturers offer virtual hardware. Commercial platforms are also becoming increasingly available, simplifying the integration of these components.

Helbling has demonstrated the added value of this approach and has achieved significantly shorter development times, for example, where the mechanical system design or actuator layout could already be optimized virtually. The software and firmware maturity could be increased before implementation in the real hardware to such an extent that effective commissioning and testing could be completed significantly faster.

Cuckoo children also pose a challenge here

Seemingly simple circumstances may limit the benefits of digital twins. Namely, this involves the consistency of different architectures, proprietary protocols, and data models from different system providers. Under certain circumstances, the effort of interface handling outweighs the effective benefit. Unfortunately, large system suppliers offering actuators, sensors, control hardware and software, and proprietary development environments have rather limited interest in opening their platforms to third-party providers; they often prefer to emphasize the advantages of an “one-stop shop” approach. Although the realization that a certain degree of openness is necessary seems to be slowly gaining ground, support for digital integration of third-party modules is limited, especially since there are still hardly any standards to guide their manufacturers.

Helbling has a claim to the title of “best in class” when it comes to development tools. For this reason, it is currently investing in precisely this problem under the catchphrase “Digital Twins with Cuckoo Children”, tackling questions such as:

- What are the approaches that can be used to create robust digital models where elements from different suppliers interact correctly?

- How and to what extent should third-party devices be modeled?

- In which cases is the additional effort for modeling such a component worthwhile?

This is a sensitive topic for Helbling as certain clients restrict the selection of certain components to specific suppliers and Helbling’s follows the principle of approaching each task in a supplier-neutral, and thus solution-neutral, manner.

Zusammenfassung: Helbling optimiert den Entwicklungsprozess durch interdisziplinäre Plattformen

Summary: Helbling optimizes the development process with interdisciplinary platforms

More and more, Helbling is relying upon the possibilities of interdisciplinary, digital development environments for early identification, evaluation, and mitigation of technical risks and uncertainties during mechatronic system development. In addition to the shift in risk mitigation, there is also a significant reduction in development time, in particular because activities that could only be carried out using hardware in a traditional approach can be addressed much earlier in a virtual environment. Under the catchphrase “Digital Twins with Cuckoo Children”, Helbling is currently working on the interoperability of different subsystems from different system suppliers in the digital environment.

Authors: Stefan von Bergen, Ueli Schläpfer

Main-Image: The basic idea behind digital twins is to digitally map a product in its entirety. Image: Helbling / F&P Robotics AG