Referenzprojekt

Digital twins and CFD-Simulation to speed up time to market for aseptic isolators

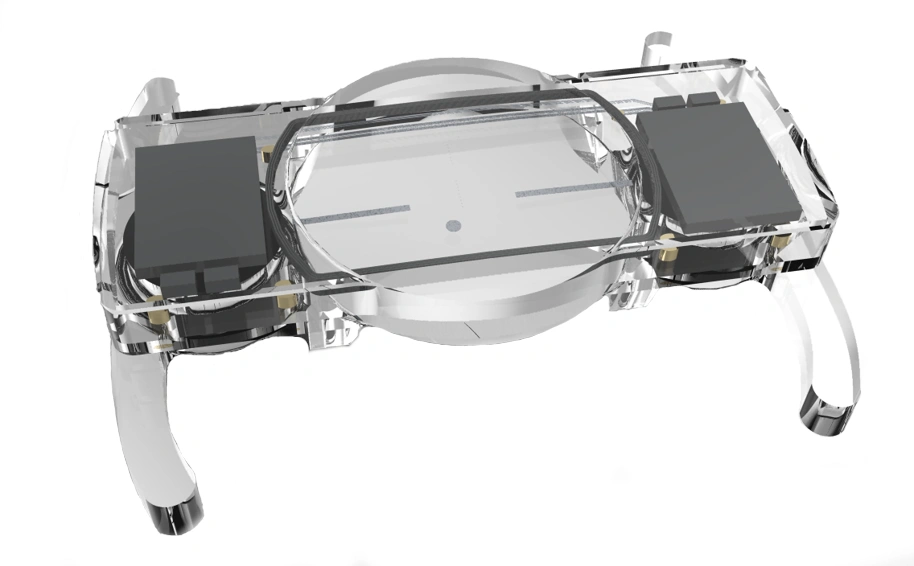

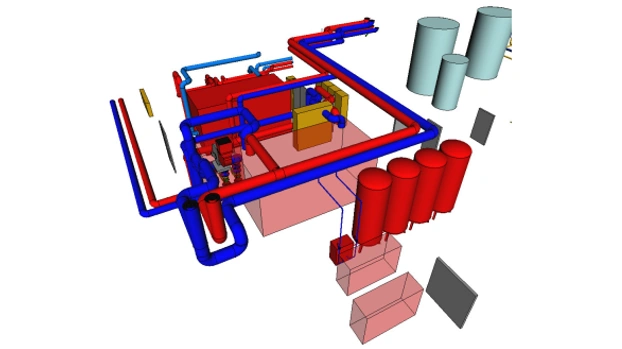

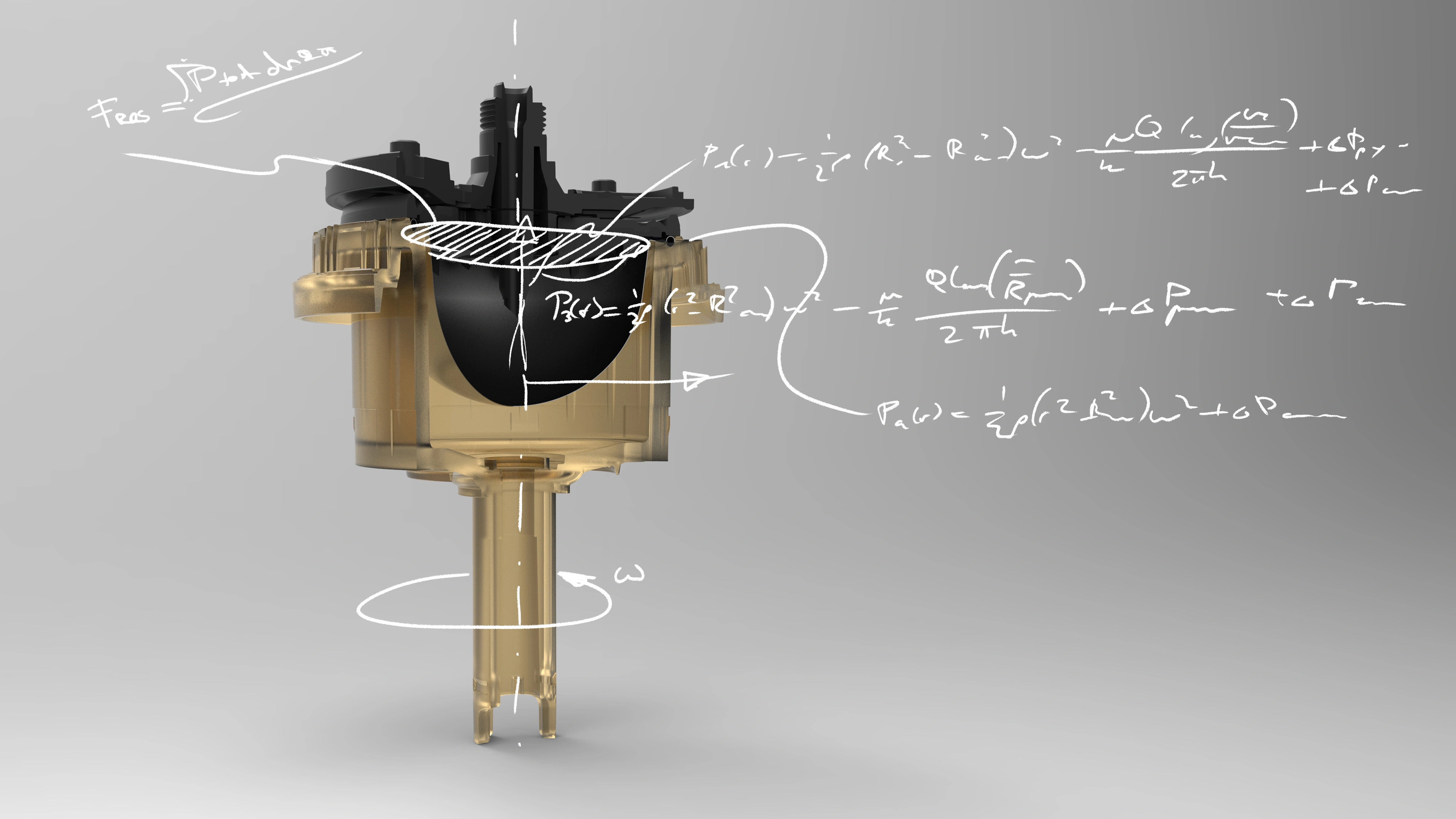

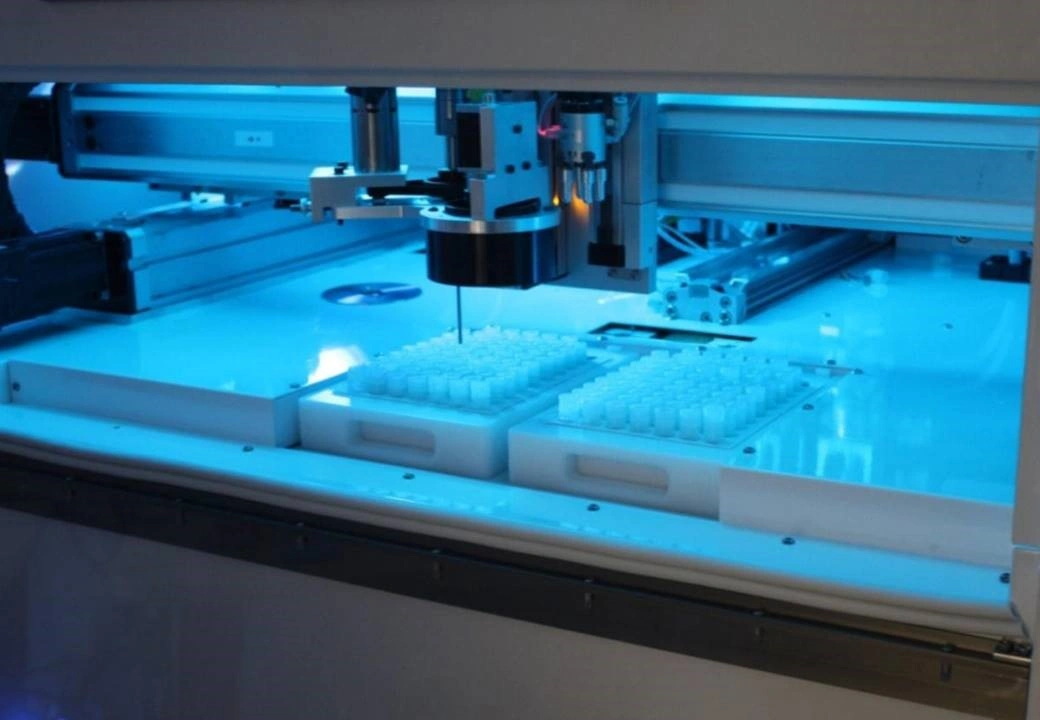

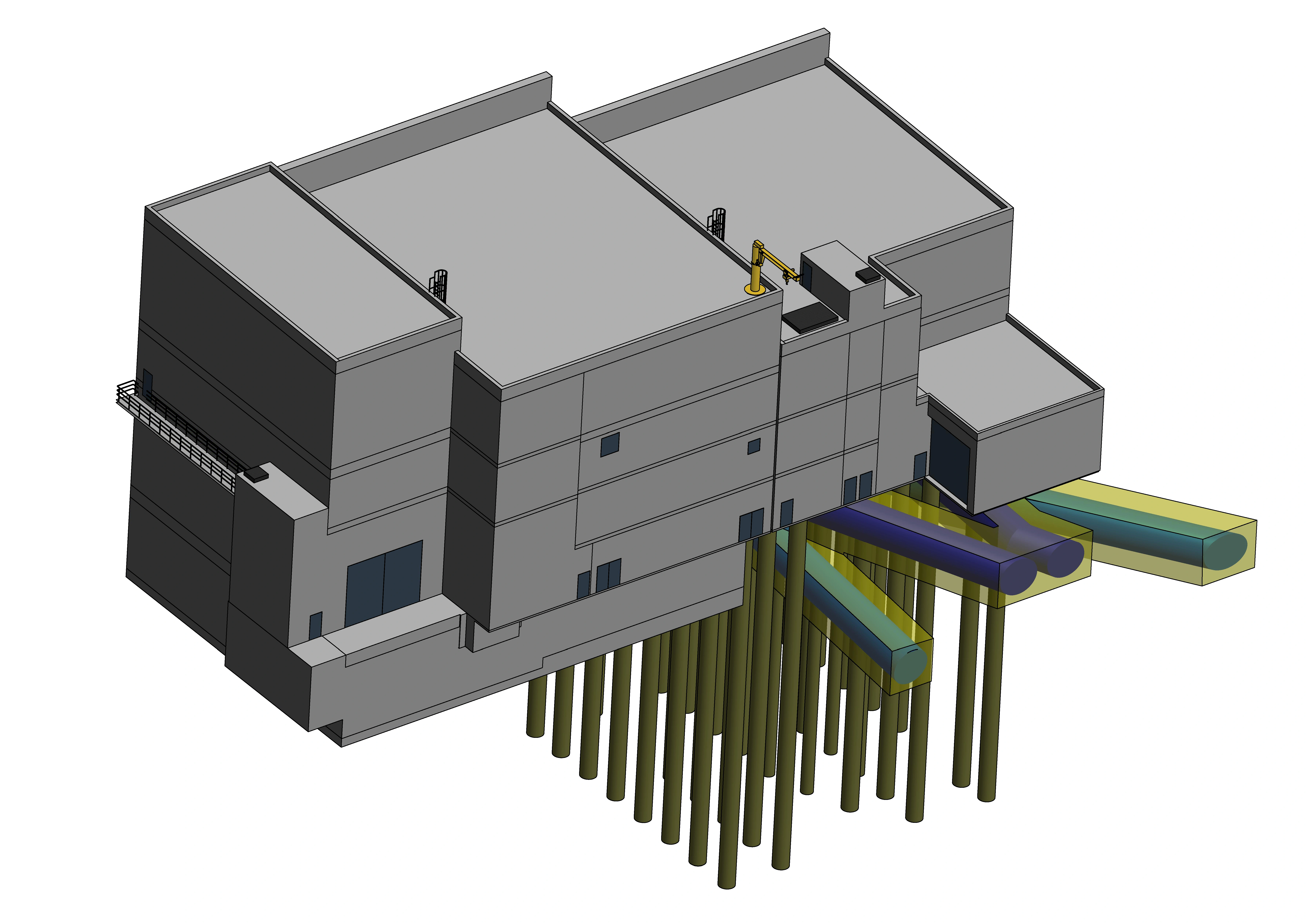

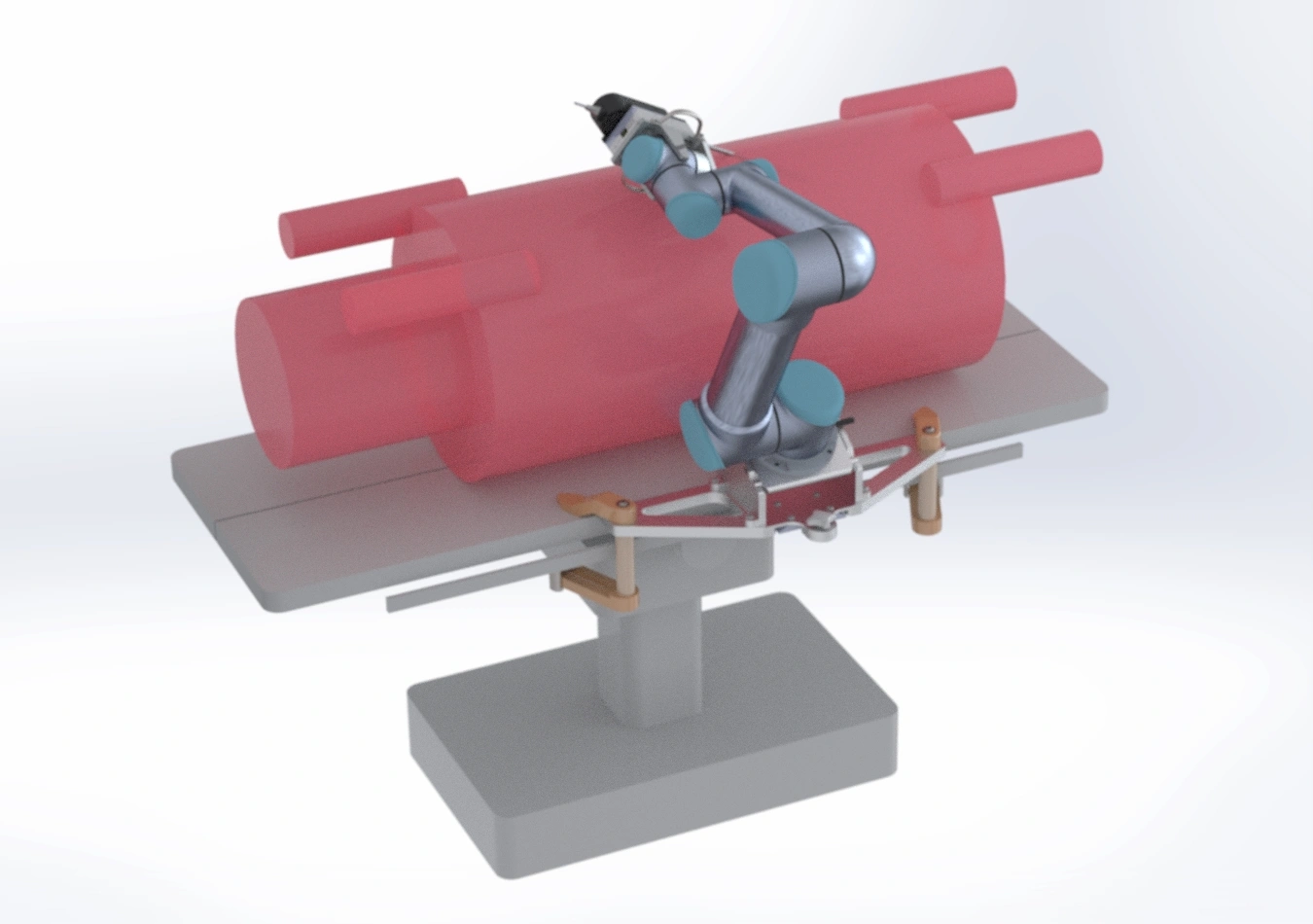

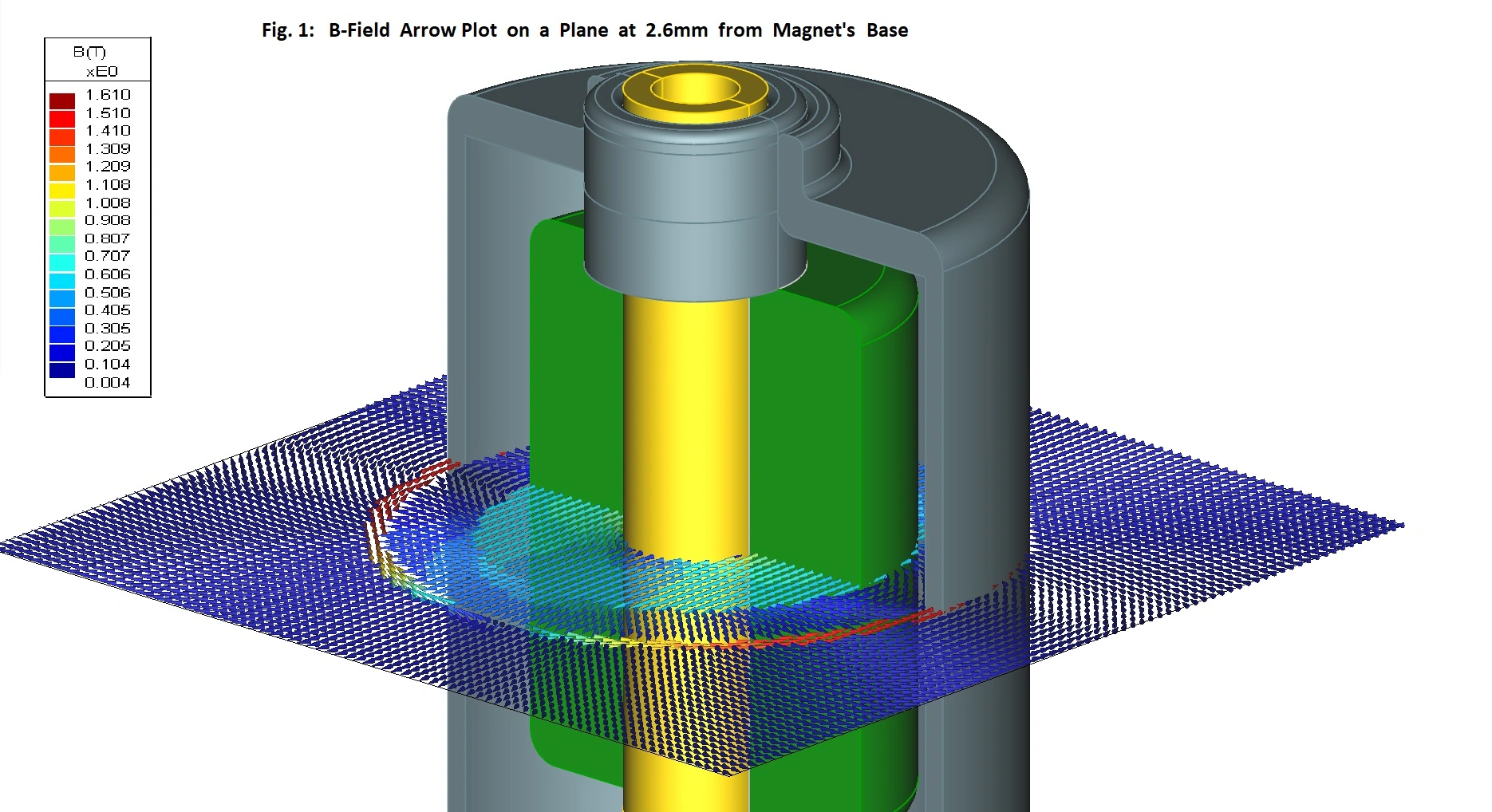

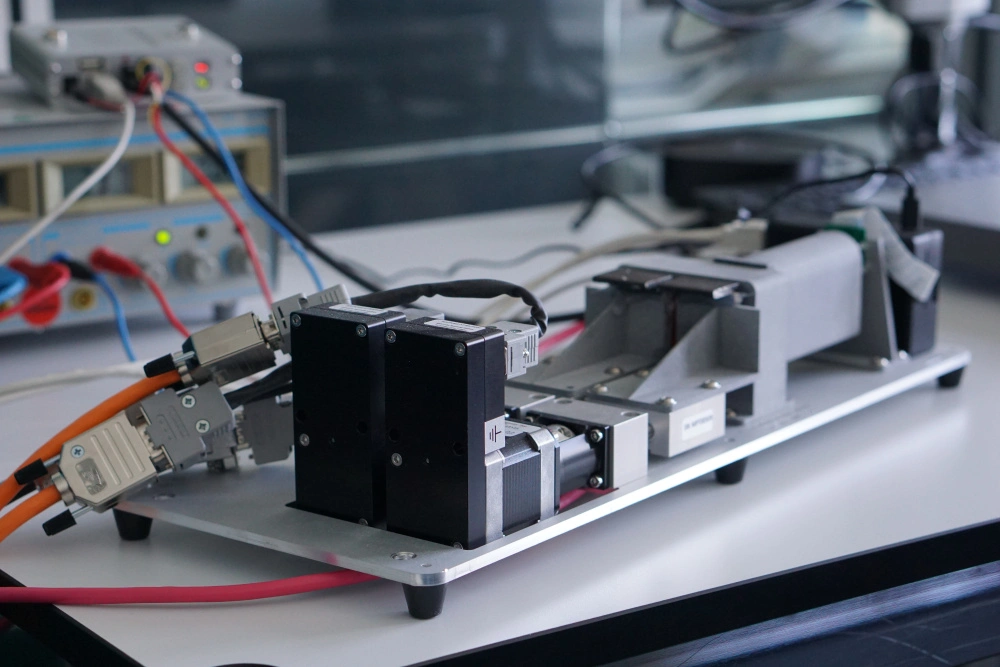

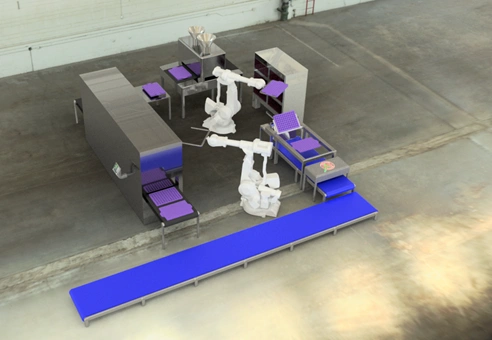

Maintaining sterility is critical in aseptic production environments such as the pharmaceutical, medical device and biotechnology industries. Helbling defined a workflow for optimising robotic operations in such environments, using transient CFD simulations to analyse airflow during robot movements. This analysis enabled the identification of critical areas prone to contamination and the optimisation of processes such as Fill & Finish, where containers are particularly exposed.

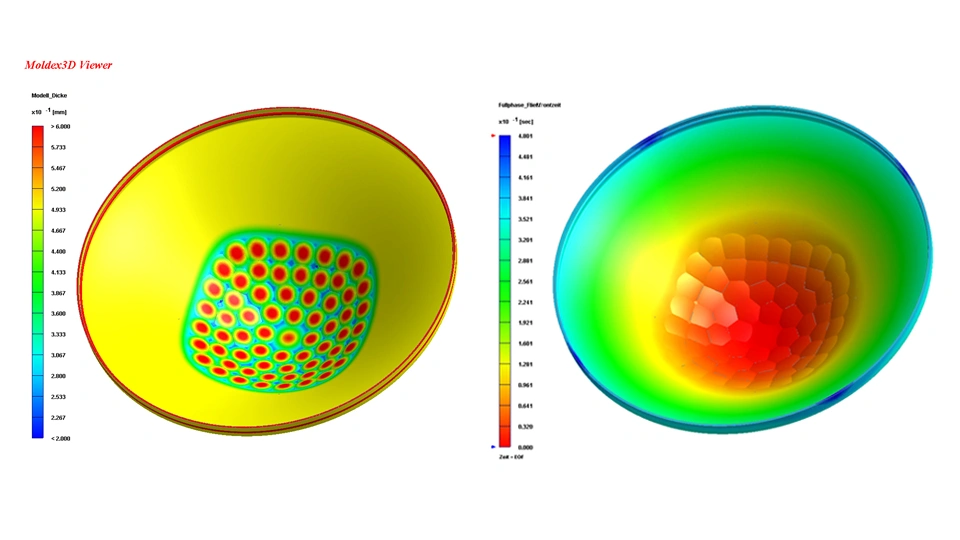

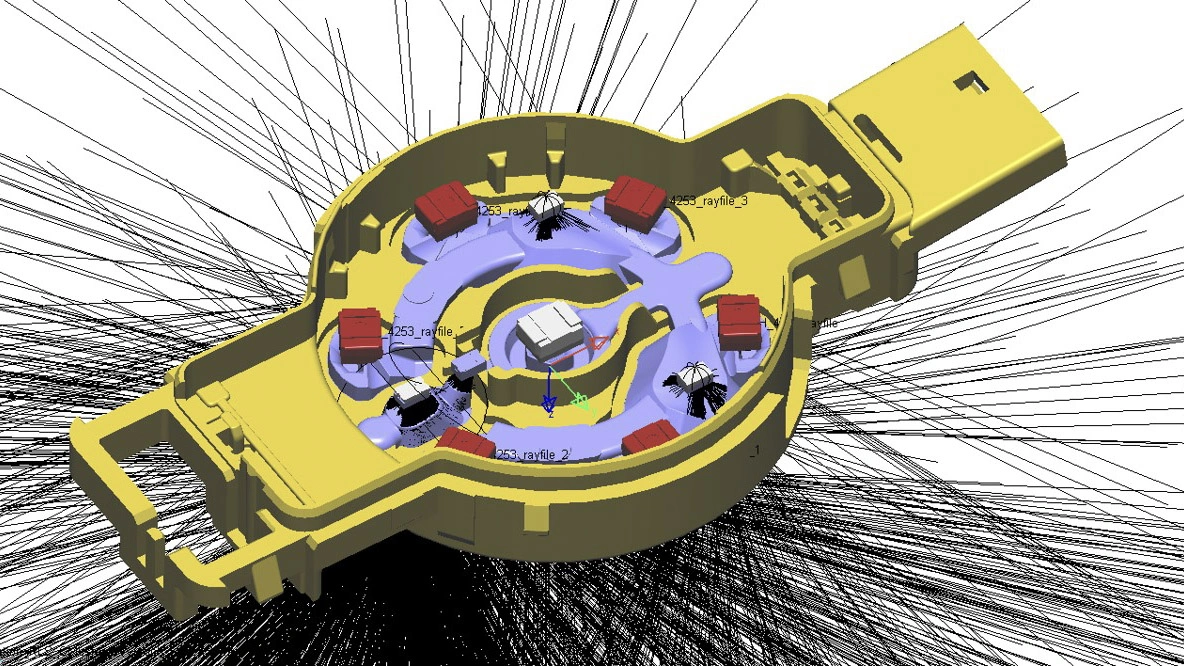

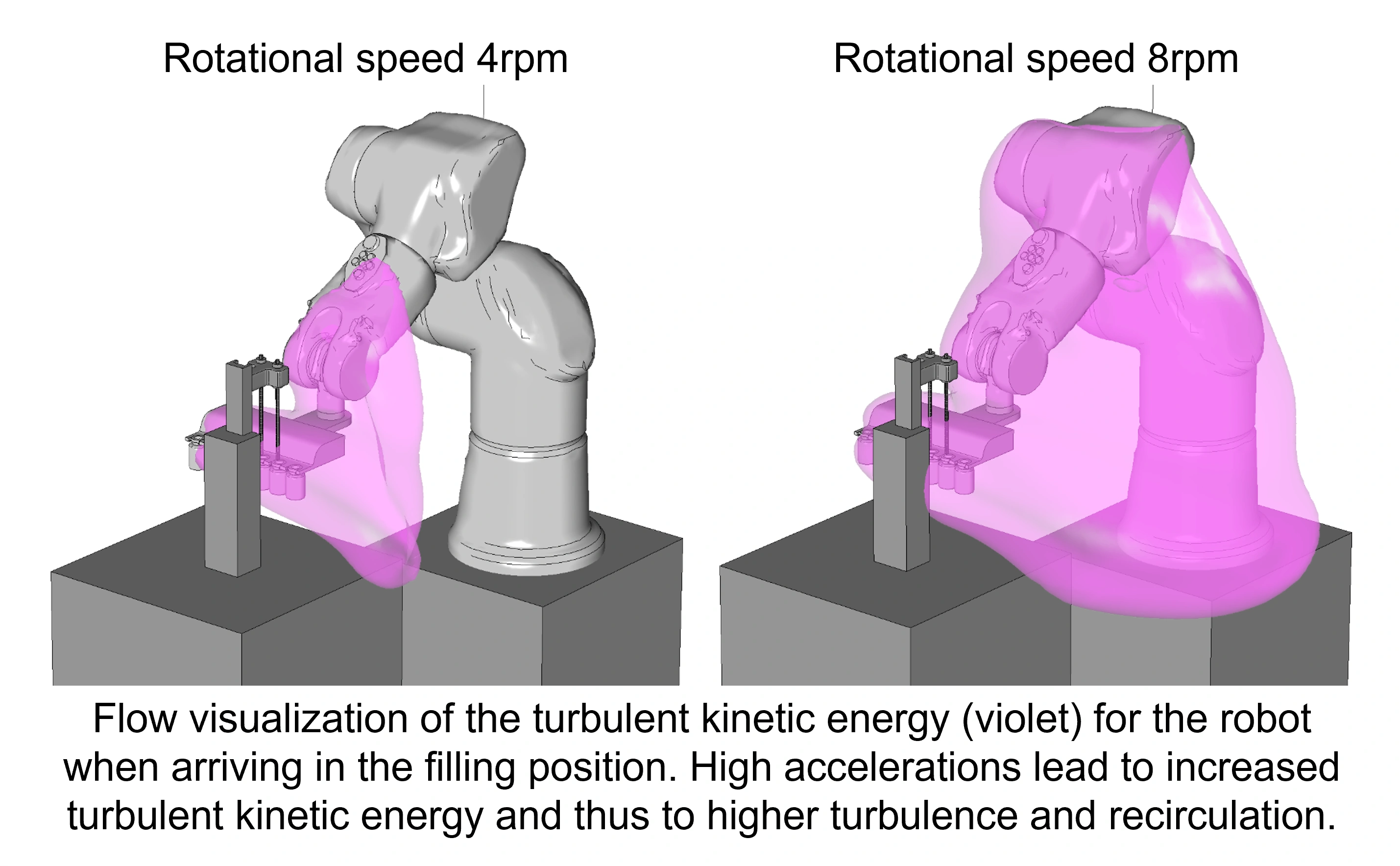

The study revealed that high-speed robot movements and improper diffuser placement could disrupt the sterile airflow, creating turbulence and recirculation zones. By iteratively combining motion planning, transient CFD simulations and optimisation, Helbling developed solutions to improve air inlet design, minimise installation space and optimise robot trajectories, ultimately increasing cleanliness and efficiency.

Helbling's strength in this project lay in its interdisciplinary expertise in robotics, fluid dynamics and simulation. This approach provided allows for a tailored solution that reduces validation costs, accelerates time-to-market and ensures compliance with stringent regulatory standards.

Key Figures

- Steady-state CFD simulation fails to capture dynamic effects

- New workflow established

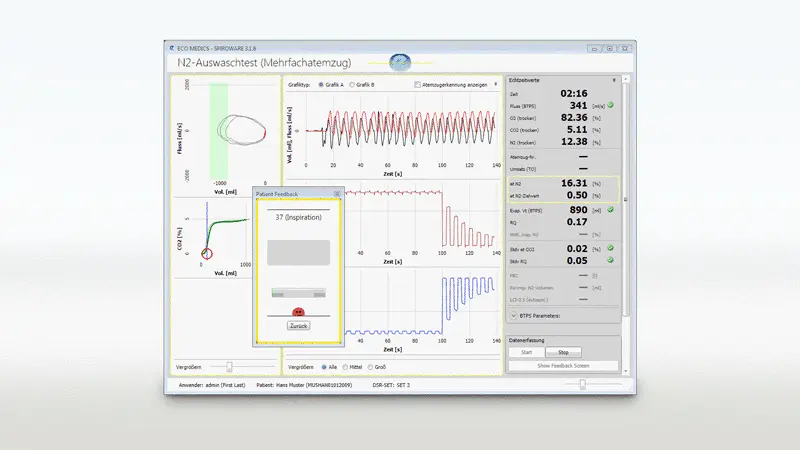

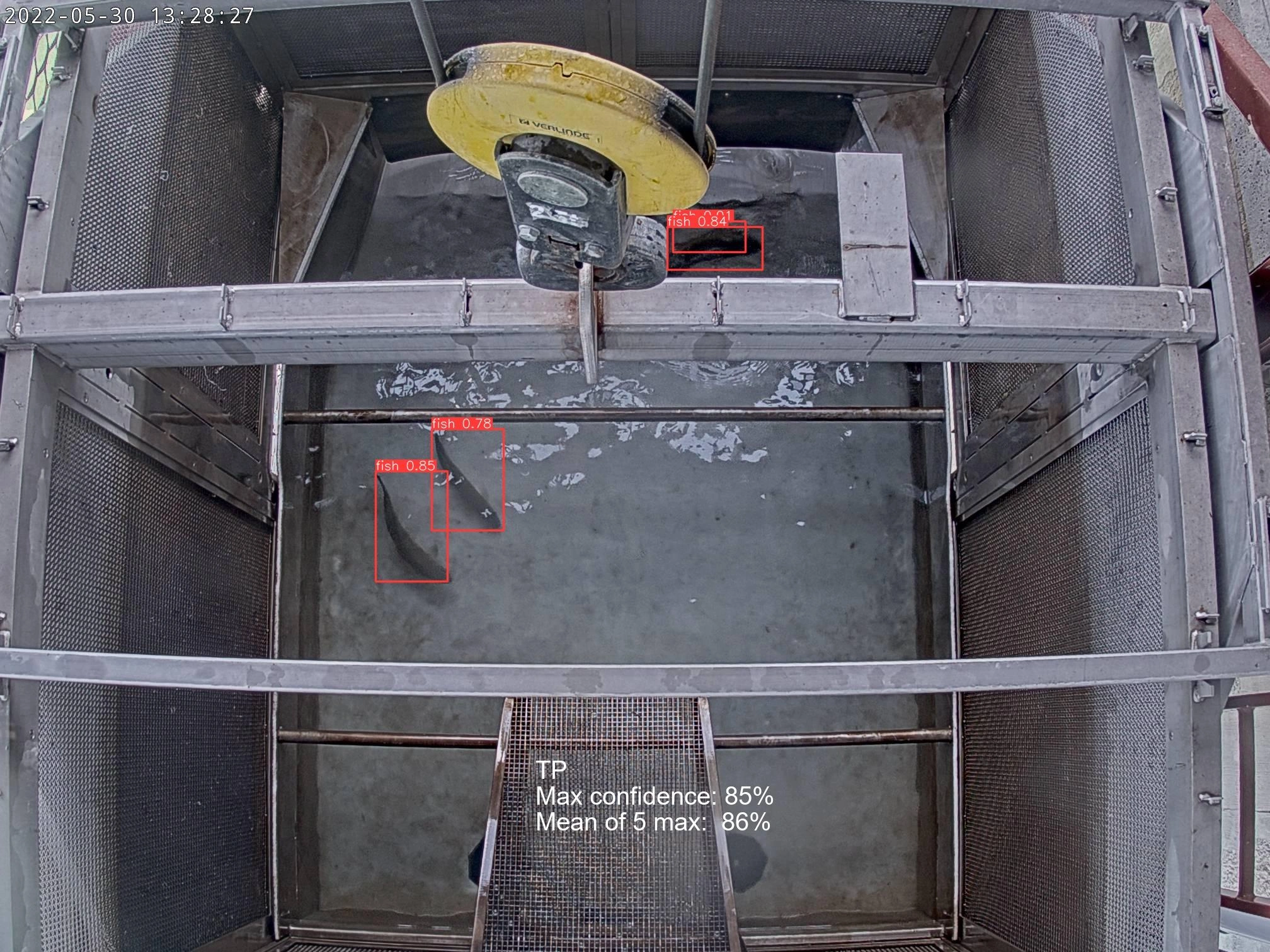

- Transient CFD simulation of robotic arm in aseptic environment

- Evaluation of critical areas using streamlines and turbulent kinetic energy

- Robotic arm motion planning, export and import

- Optimization of robotic arm motion based on CFD simulation results

- Optimization of air inlet and diffuser placement for uniform airflow

- Optimization of platfrom and tool geometry to minizie obstructions

Click to play video

Our Contribution

- Interdisciplinary team of experts

- Robotics and simulation expertise for seamless integration

- Combination of motion planning, transient CFD simulation and optimization

- Set-up, execution and evaluation of transient CFD simulation

- Identification of critical recirculation zones

- Detailed analysis of airflow behavior during robotic arm motion

- Evaluate turbulence caused by robotic arm motion

- Customizable solution to meet specific customer needs

- Reduce time-to-market, development and validation costs

Outcome

The iterative process between motion planning; transient CFD simulation and optimization is established. This allows us to understand the airflow patterns around a moving robot without the need for physical prototypes and costly smoke tests. Ultimately, this leads to faster time-to-market and reduced development and validation costs. In partnership with our customers we develop customized, highperformance solutions that bring innovation and precision to any controlled environment.

Contact

Cases

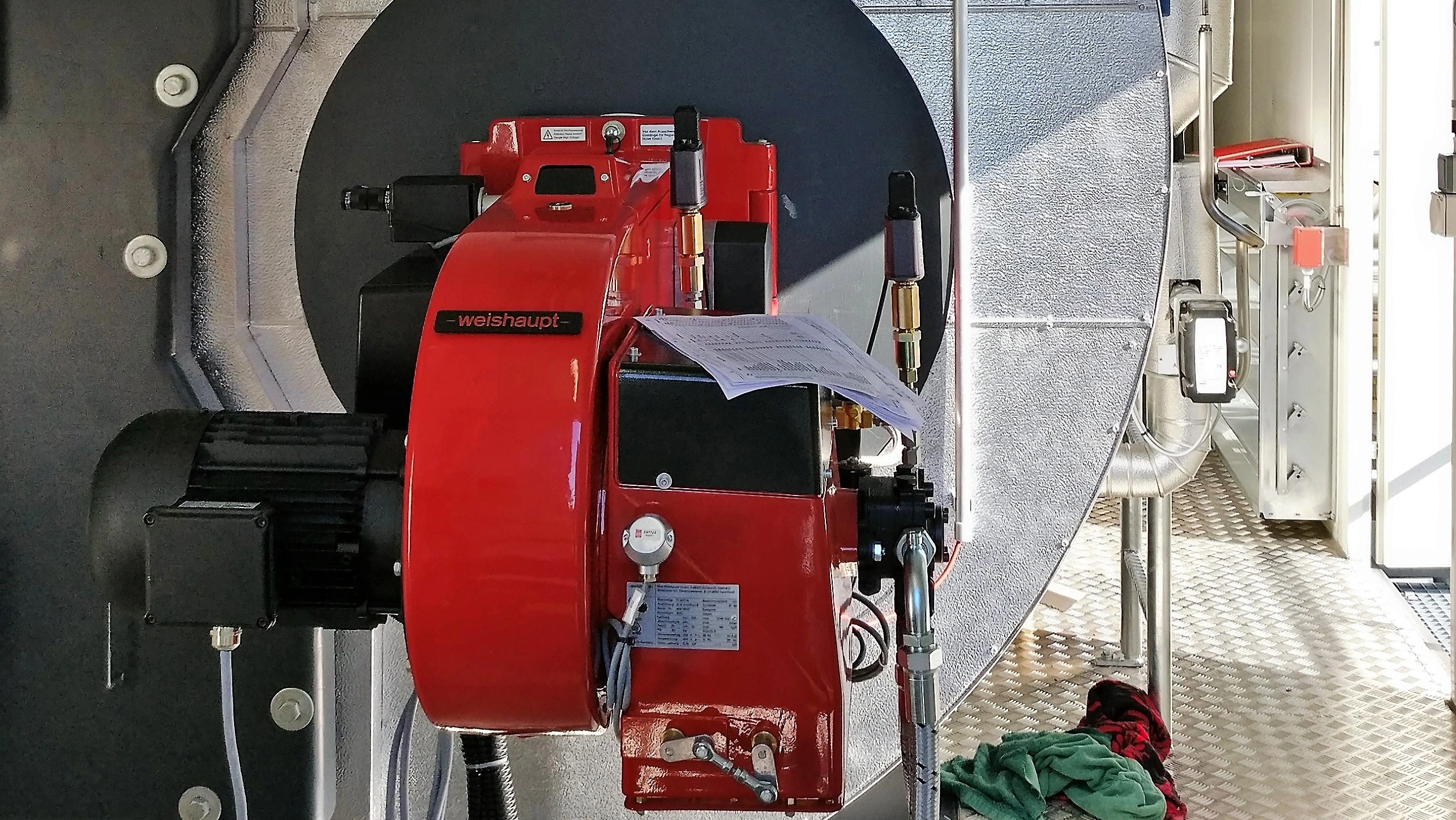

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

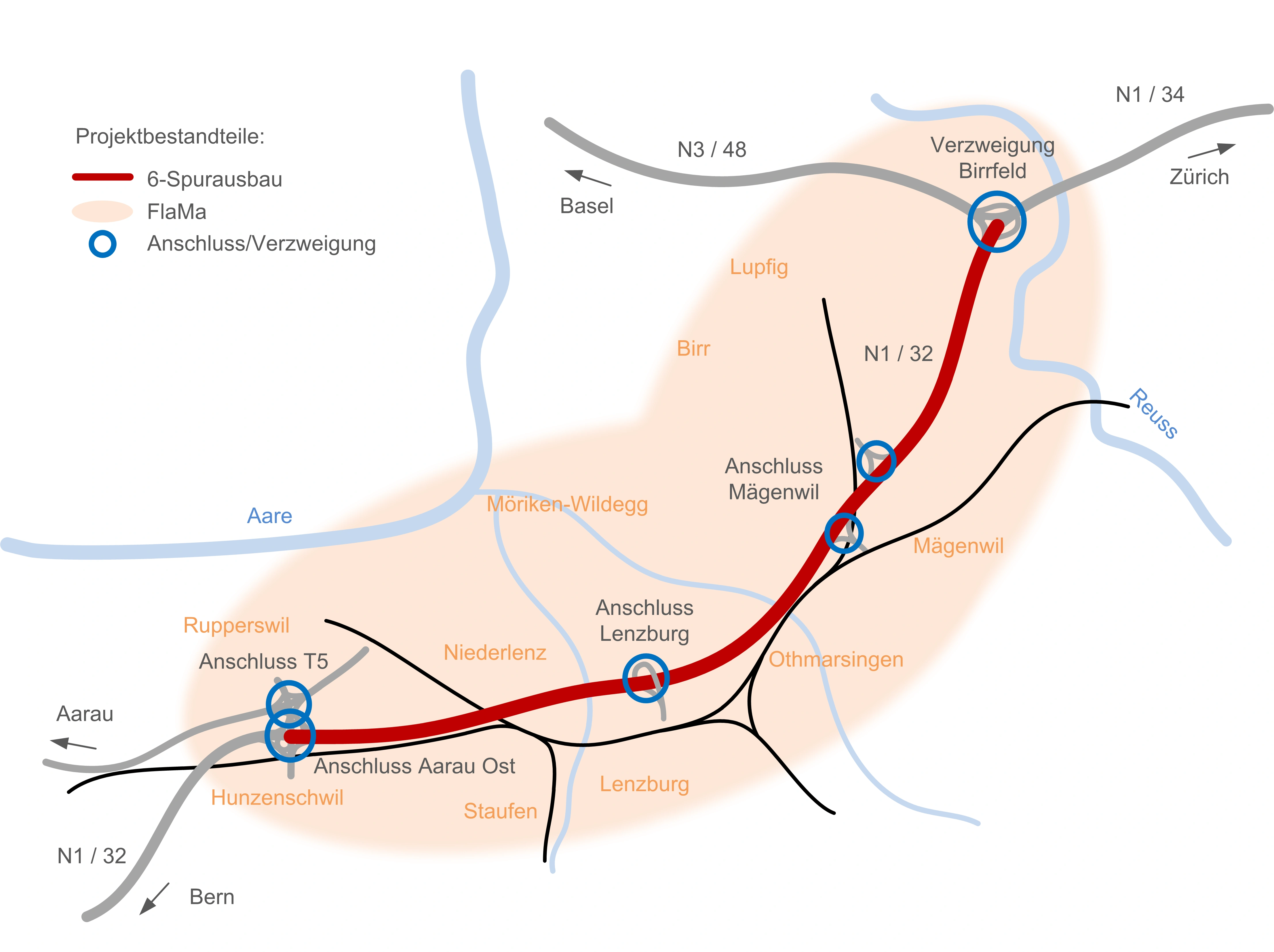

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: