Project

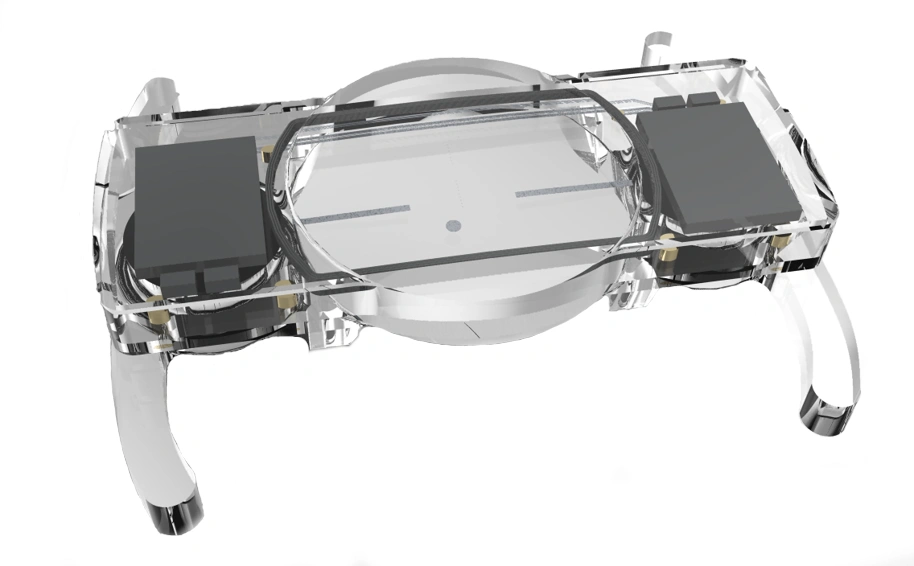

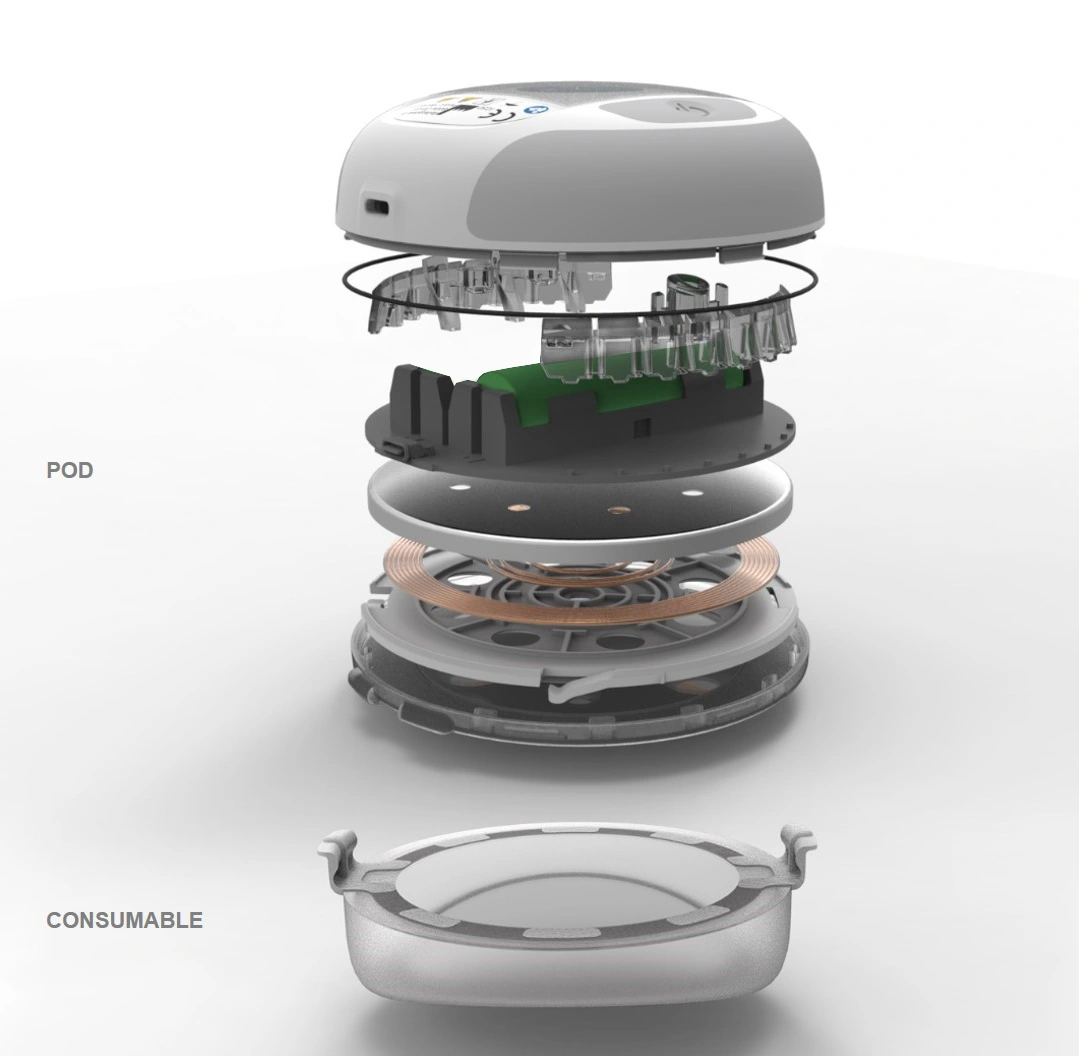

Automated Frozen Sample Aliquotter

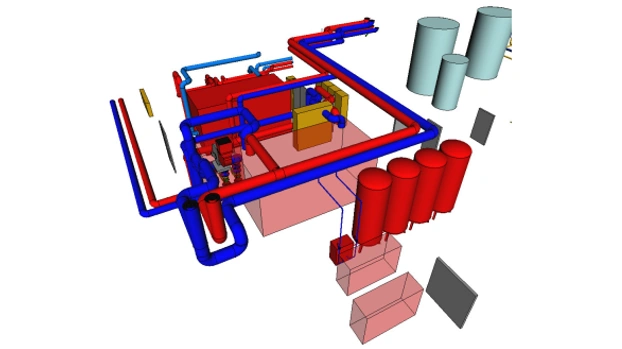

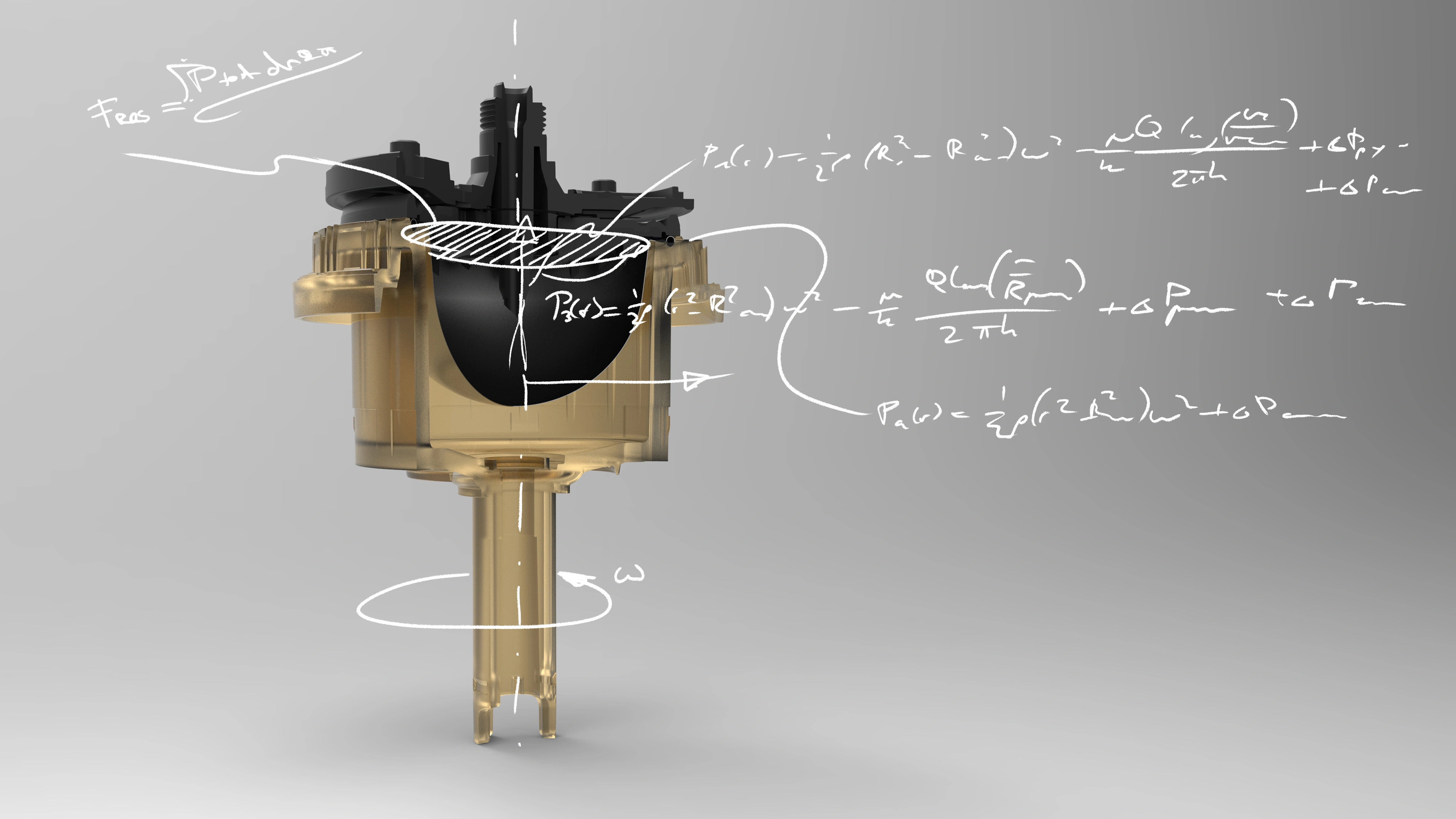

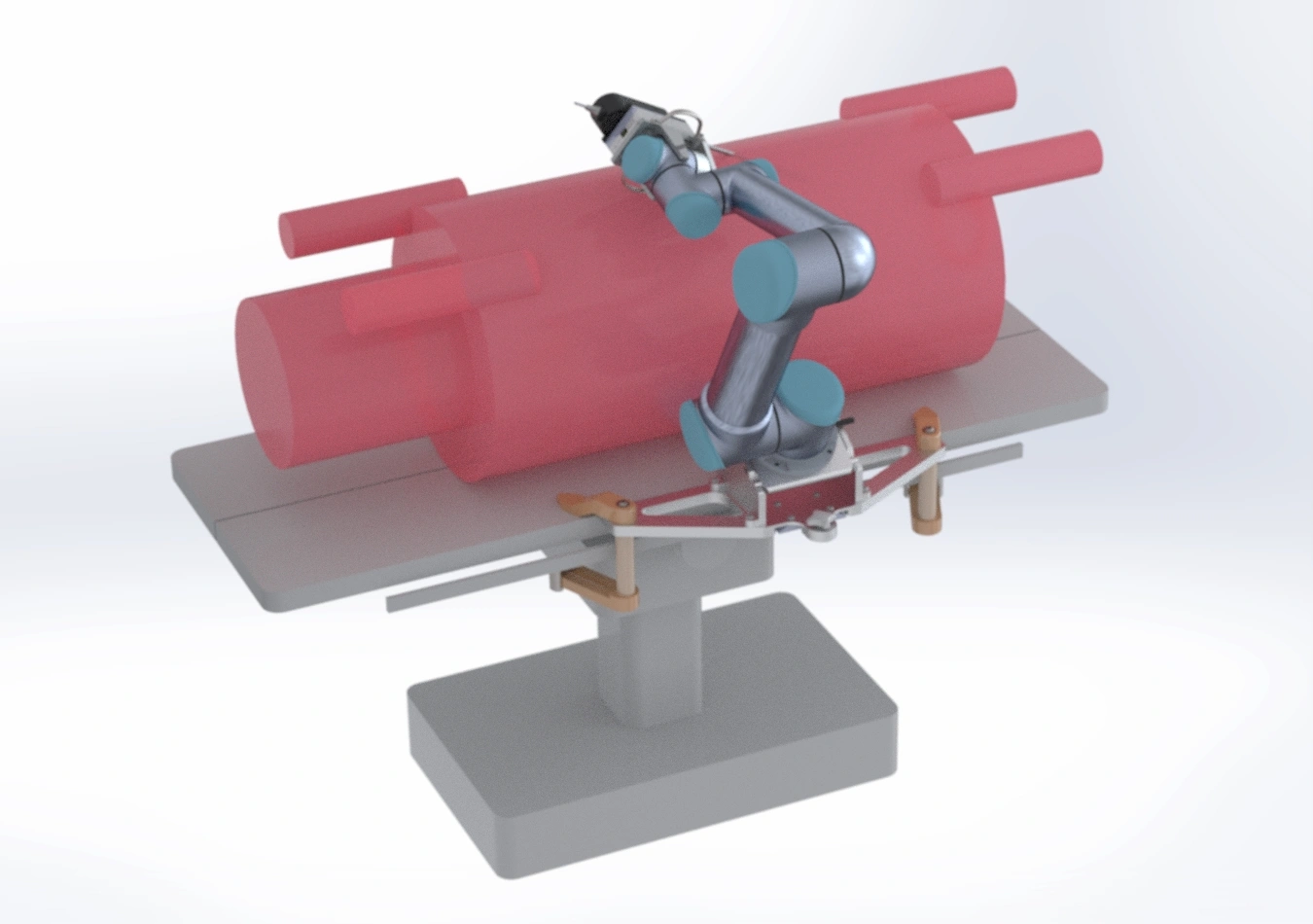

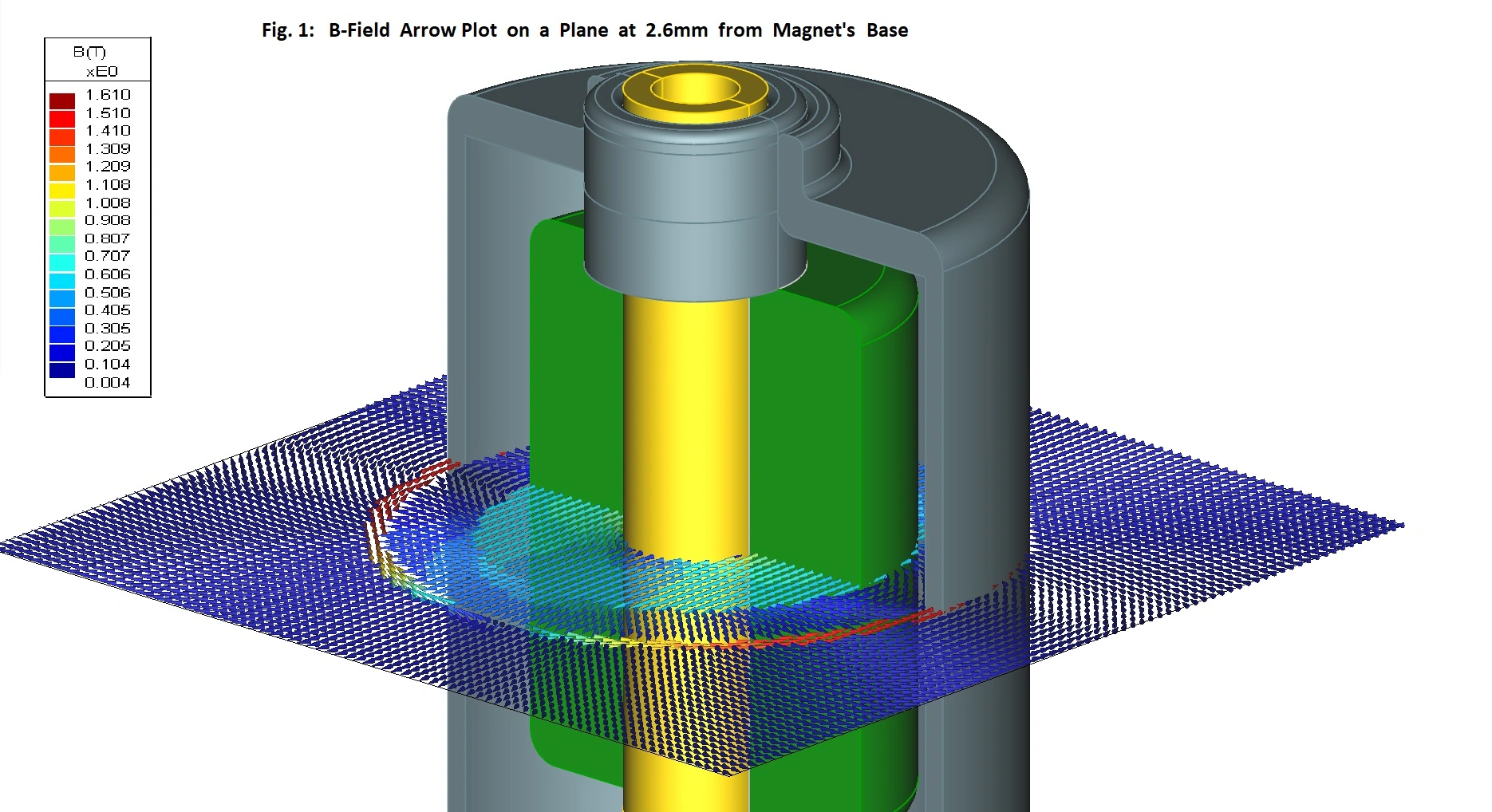

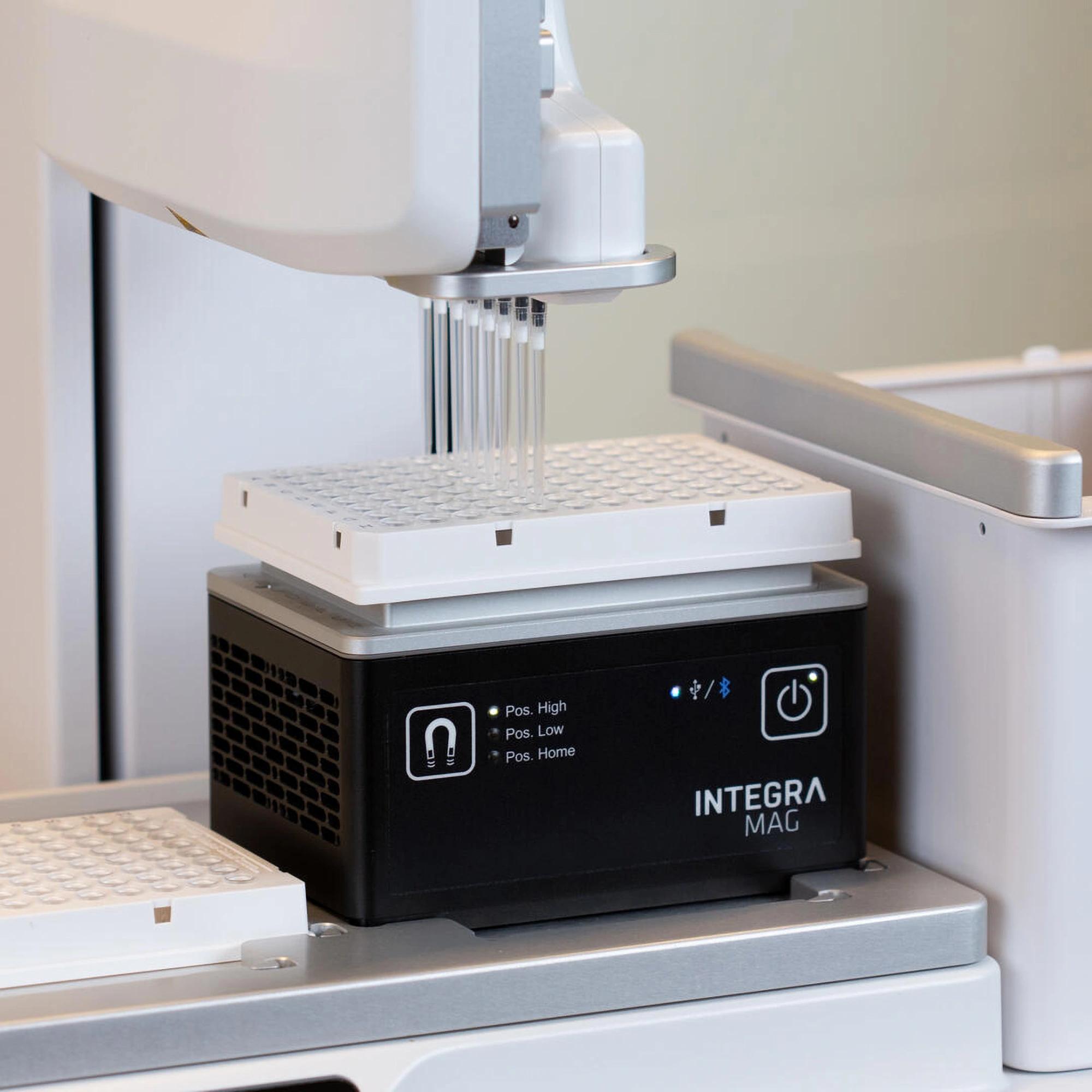

Our client specializes in the development of automated Frozen Sample Aliquotters (aFSA). These systems allow for the retrieval of multiple frozen samples from a single frozen biospecimen without exposing the source specimen to the freeze/thaw cycling. This unique process increases sample quality, the utilization of specimens and process efficiency while reducing overall costs for handling and storing such specimens.

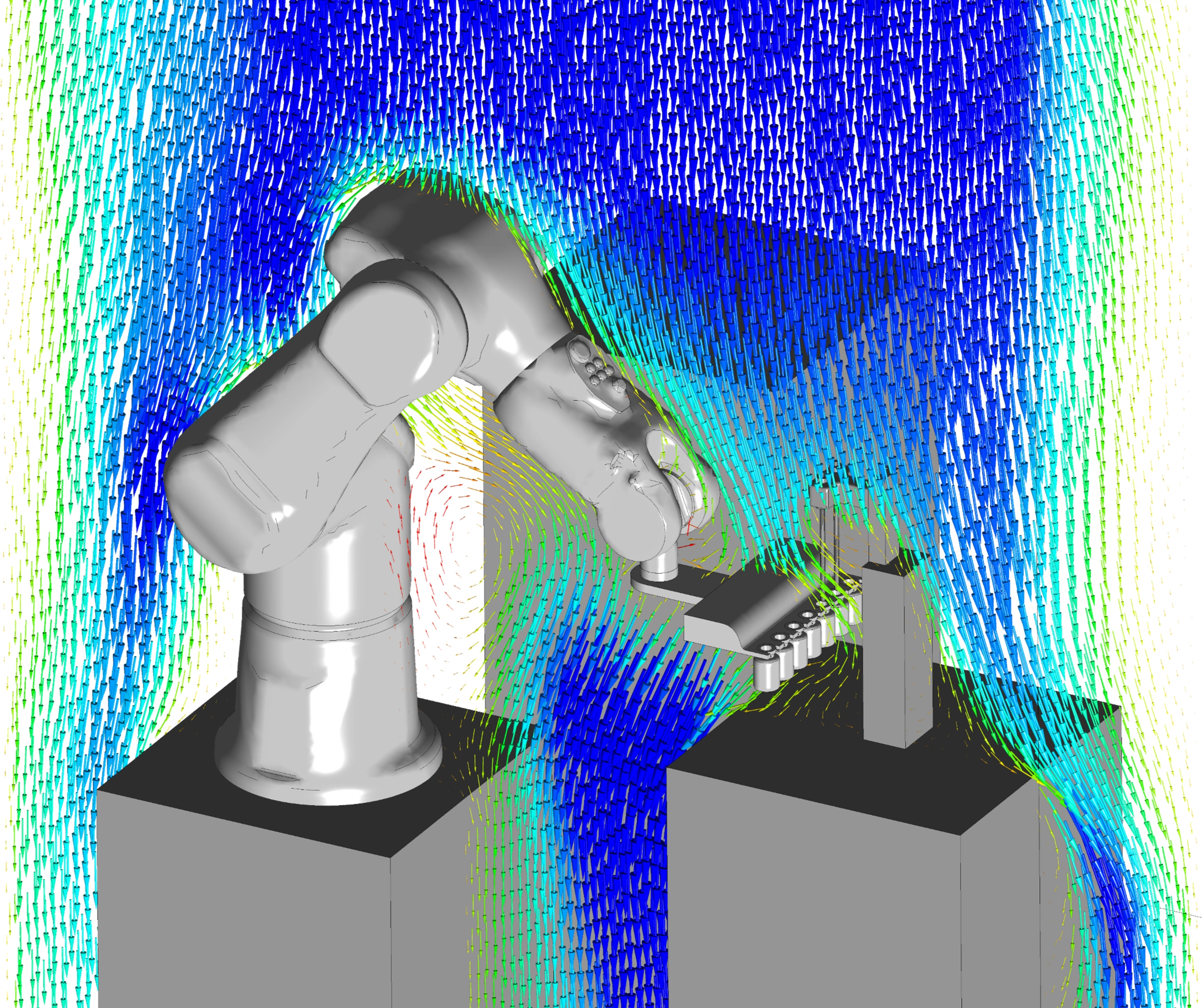

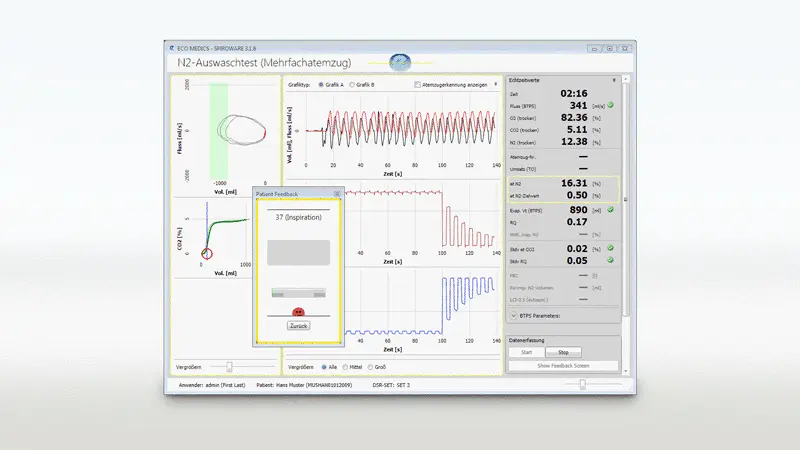

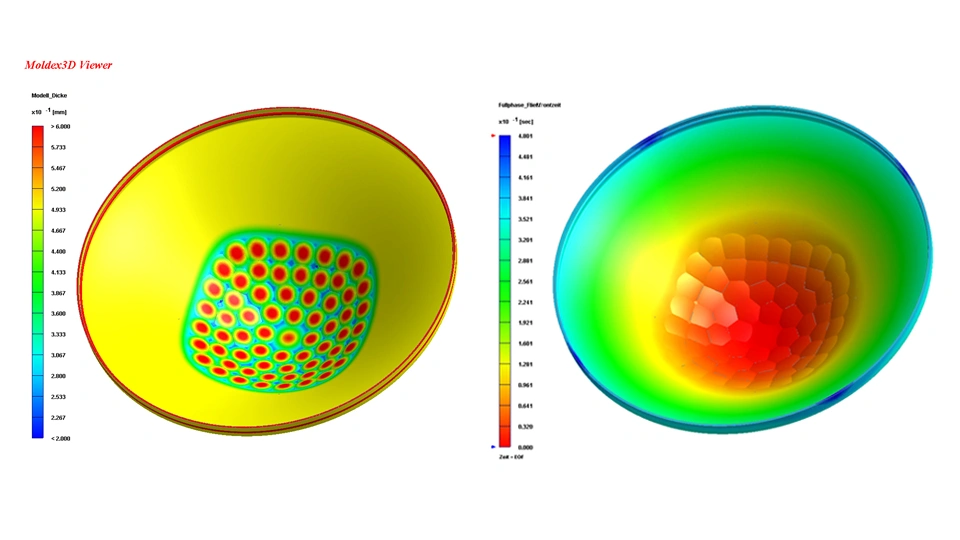

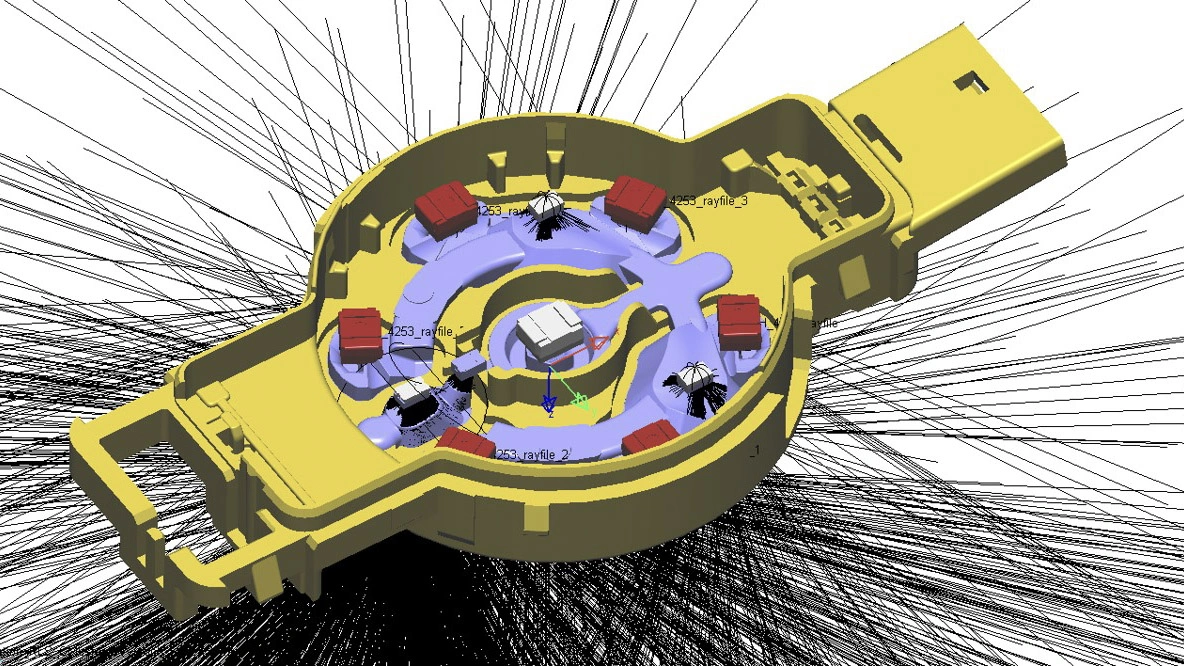

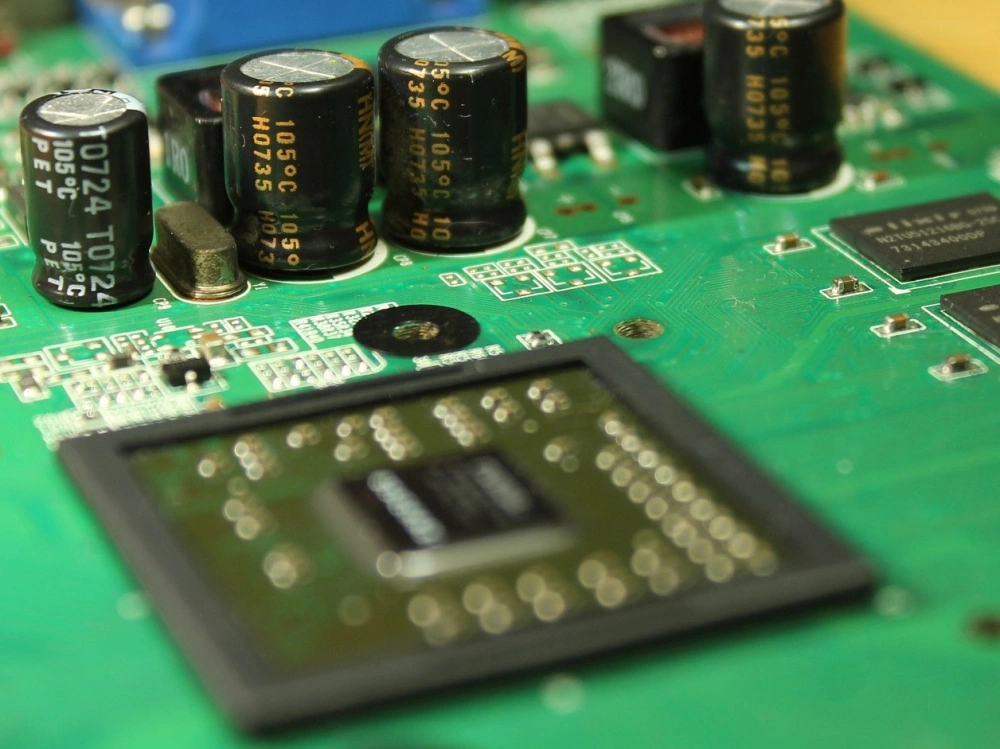

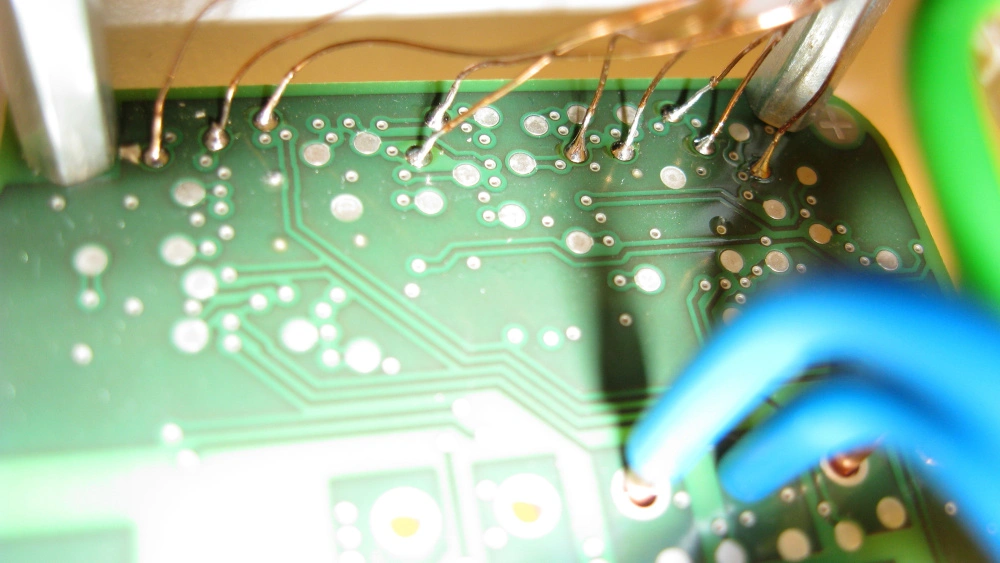

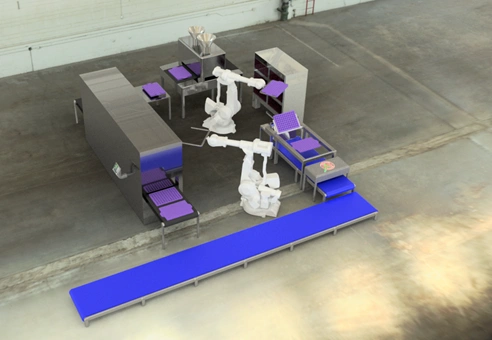

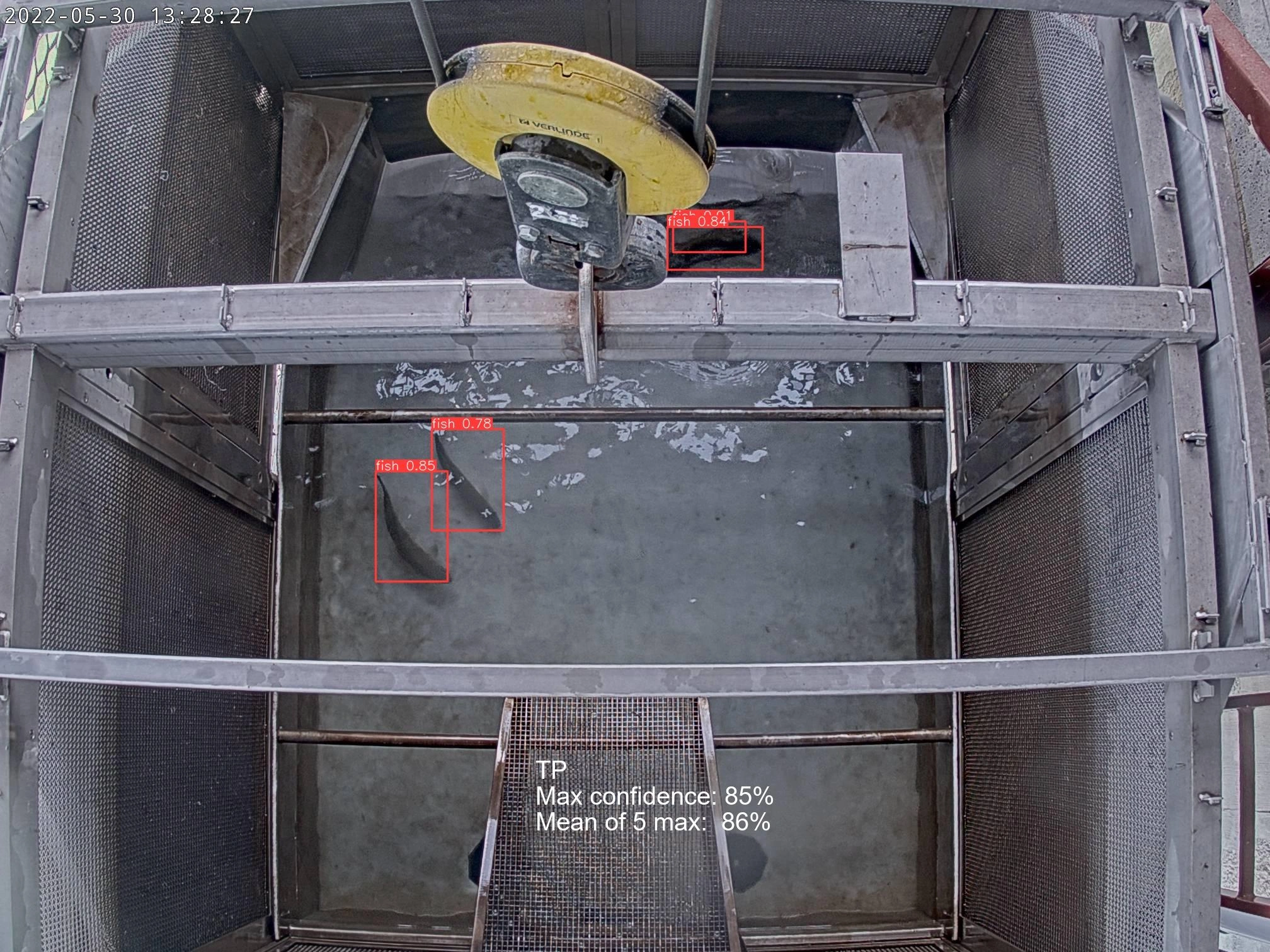

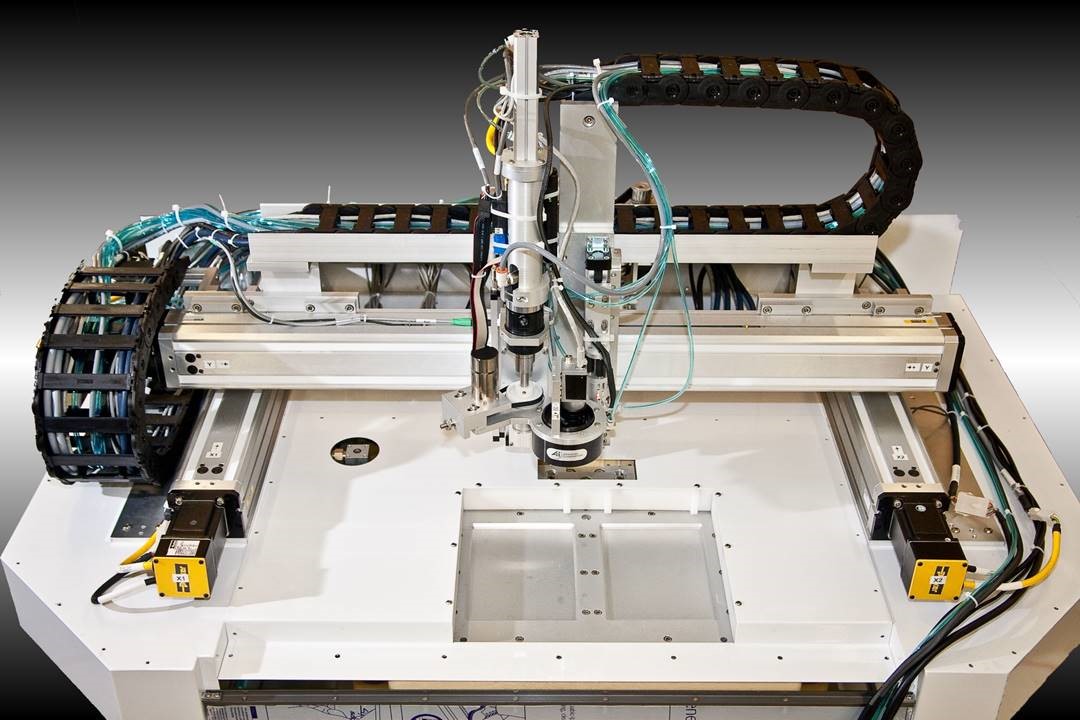

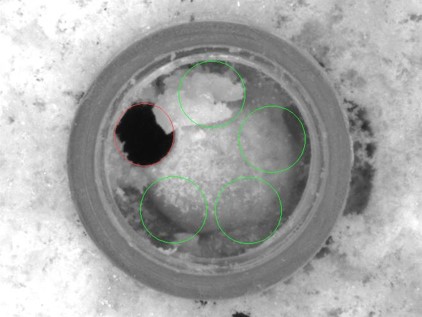

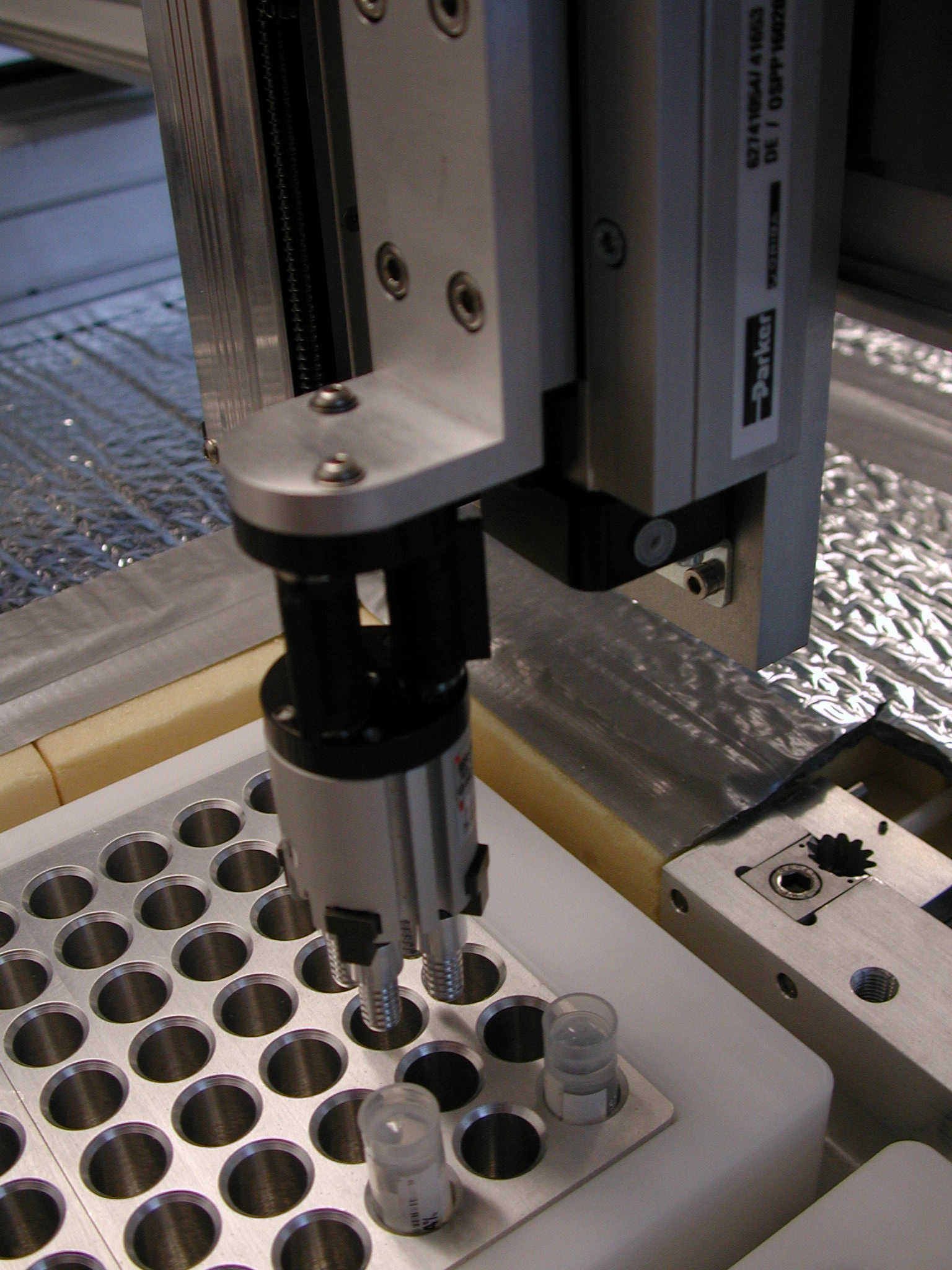

Building on our client’s frozen sample coring technology, we developed and built an ISBR award winning fully automated specimen processing systems for commercial use in record time. The aFSA features several technologies such as temperature and humidity management, robotics, sterile cleaning, vision system and pattern recognition, vial handling, operating parameter tracking, data management and a user interface.

Building on our client’s frozen sample coring technology, we developed and built an ISBR award winning fully automated specimen processing systems for commercial use in record time. The aFSA features several technologies such as temperature and humidity management, robotics, sterile cleaning, vision system and pattern recognition, vial handling, operating parameter tracking, data management and a user interface.

Industries

Technologies

Key Figures

- Fully automated lab system extracting multiple frozen aliquots from a sample,

eliminating freeze-thaw cycles - Preserve sample integrity for better scientific outcomes

- Maintain samples at ultra-cold conditions of -80°C during the whole process

- Avoid cross-contamination among samples

- Standardize sample aliquoting

- Improve lab efficiency and reduce costs

Our Contribution

- Due diligence of client’s core technology

- Requirements development for entire system

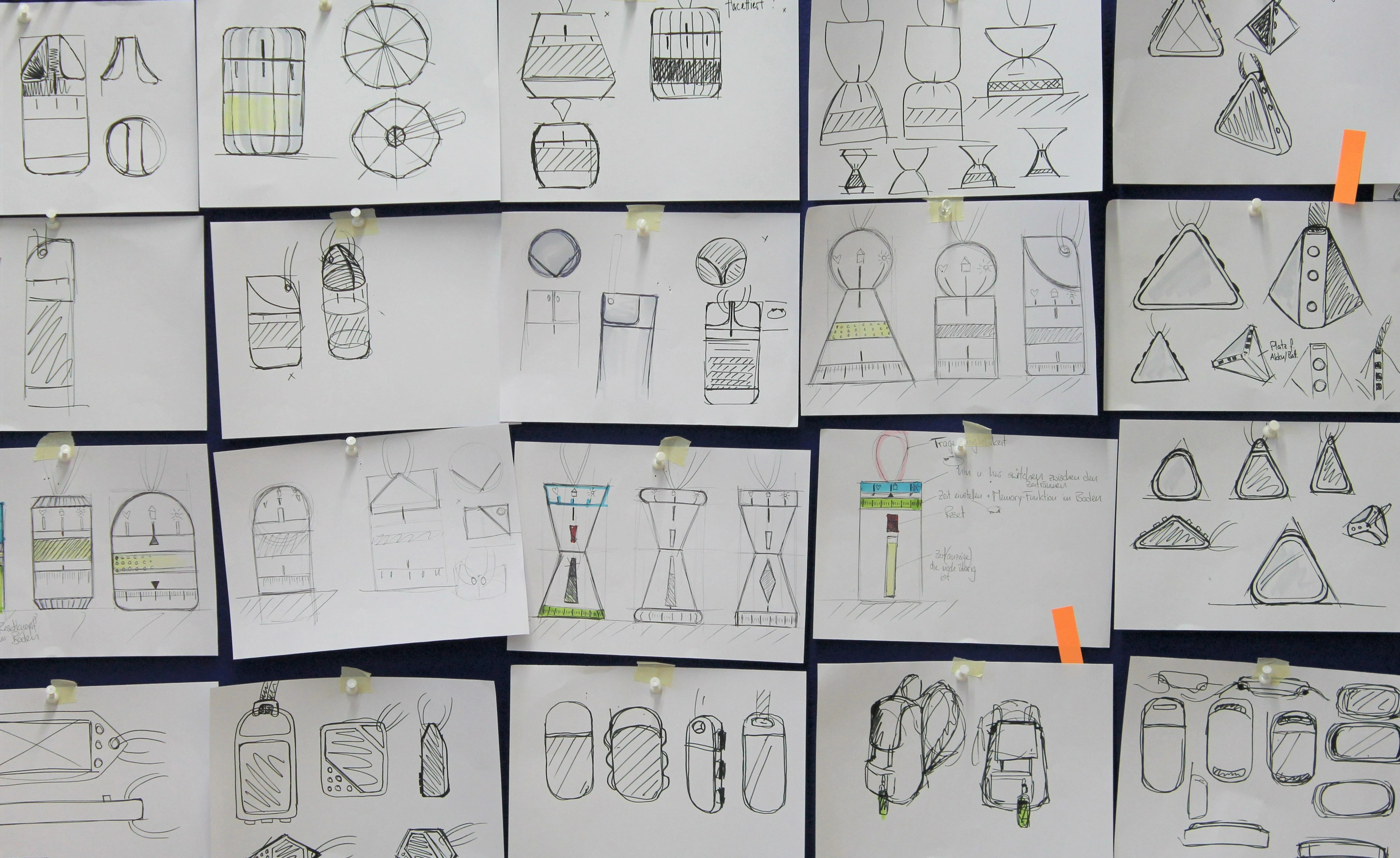

- Conceptual design and layout of entire system: mechanical, electrical, pneumatics, vision, software (LabView), usability

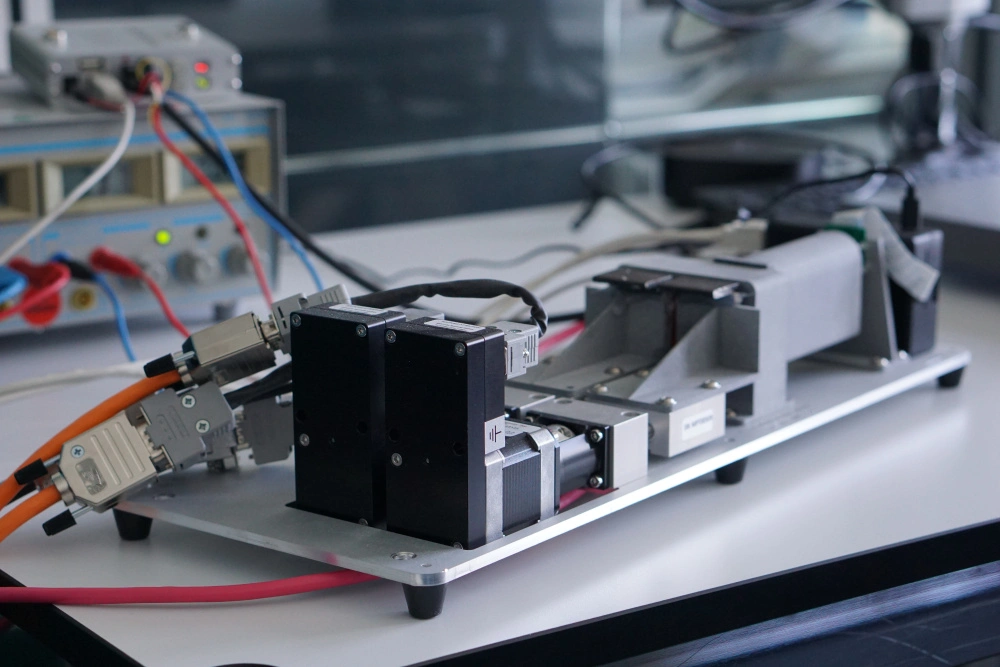

- Theoretical appraisals and build of key proof of principle (POP) modules incl. gantry robot, vision system, image processing, coring pattern recognition, cooling system, drill cleaning/sterilization, specimen level sensing

- Detailed design of entire system based on POP test

- Creation of manufacturing documents, interaction with vendors to source all parts

- Development of verification test protocol and reports

- Build systems and perform verification and acceptance tests

- Support design transfer to client’s manufacturing partner

Outcome

- Developed, built and tested ISBR award-winning, fully automated systems in record time

- Facilitated manufacturing transfer in support of commercial launch

Contact

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

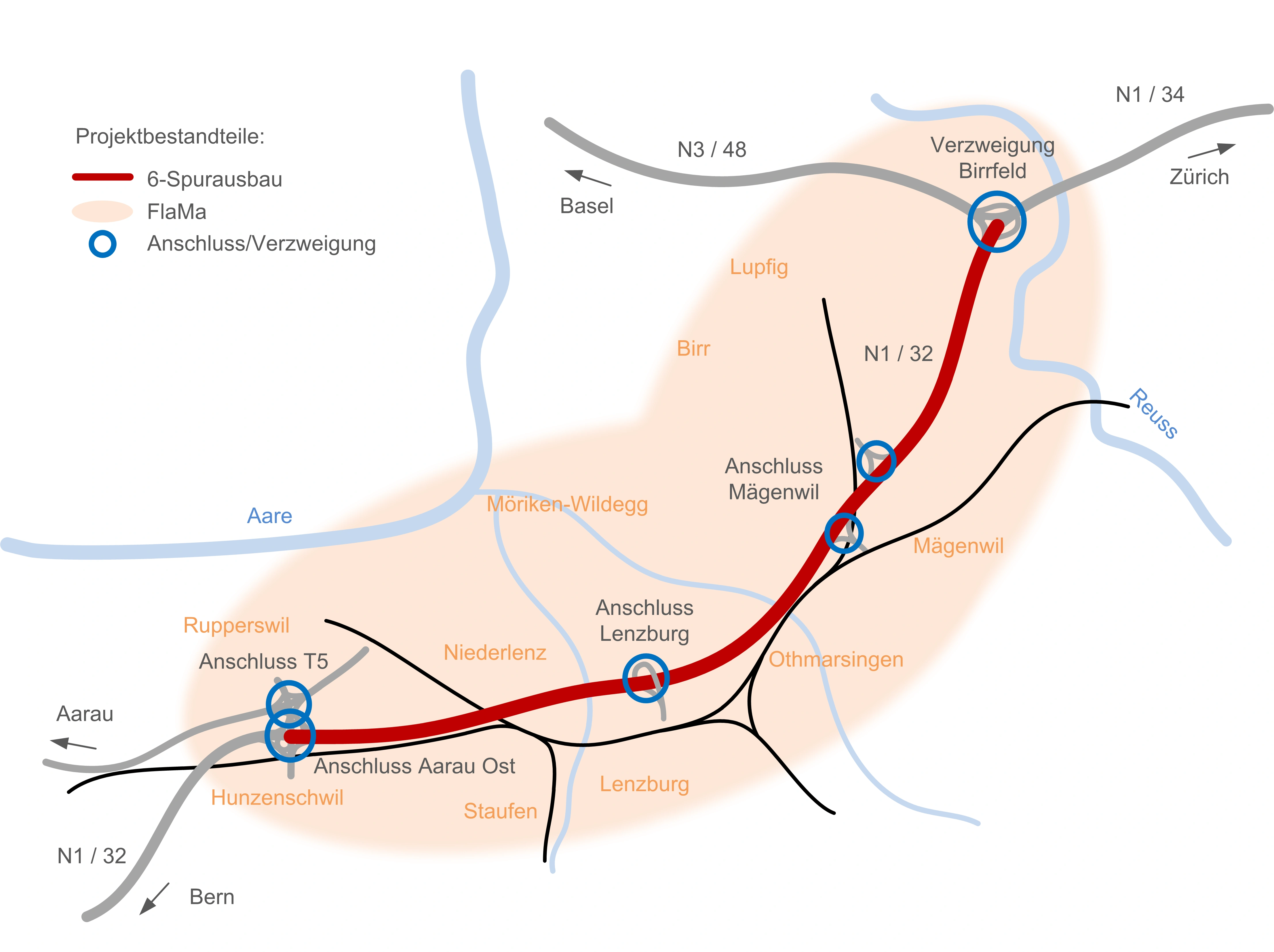

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: