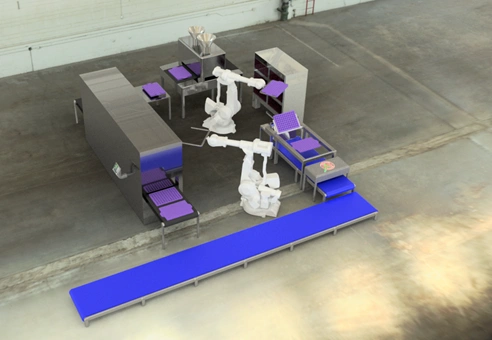

Project

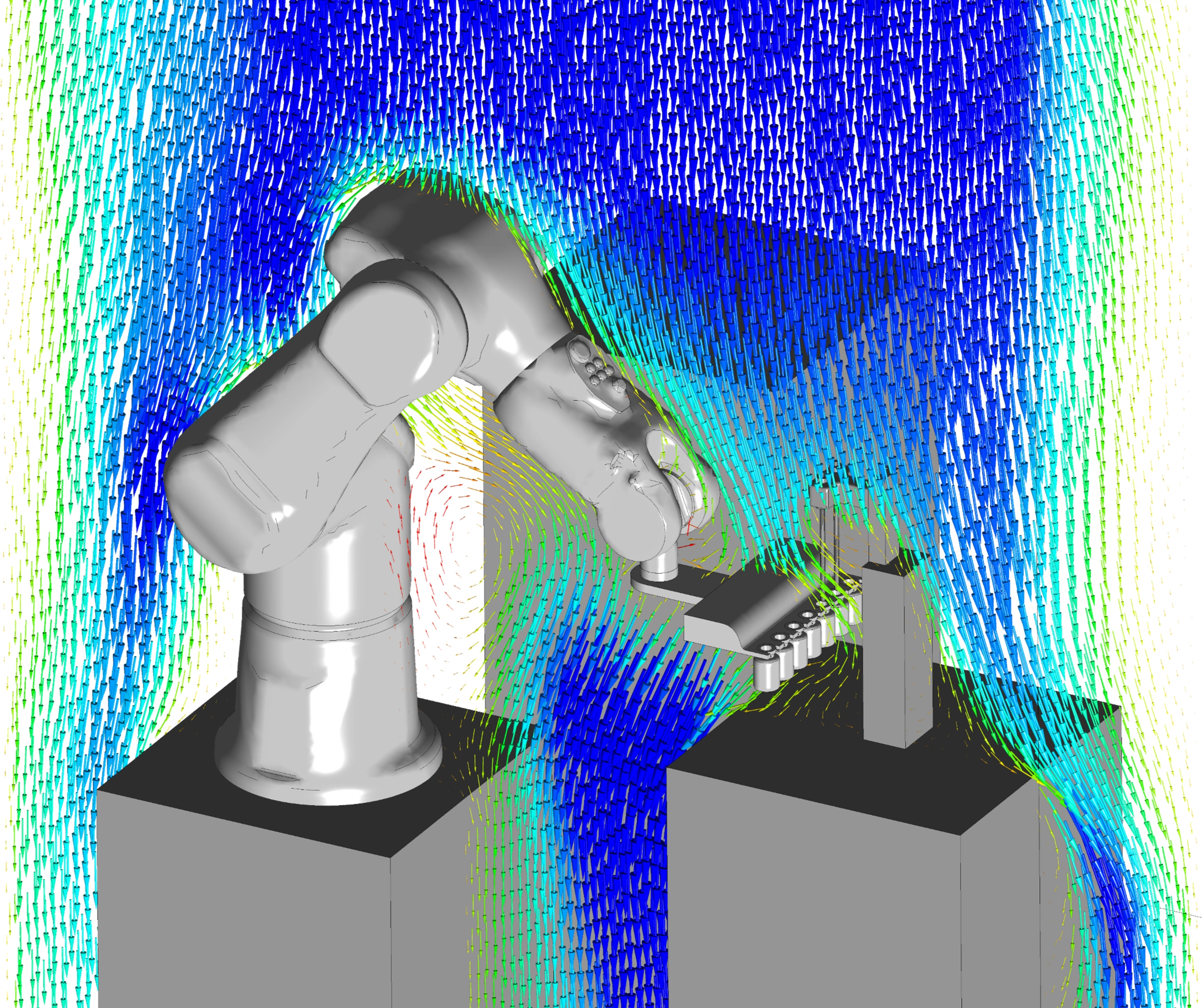

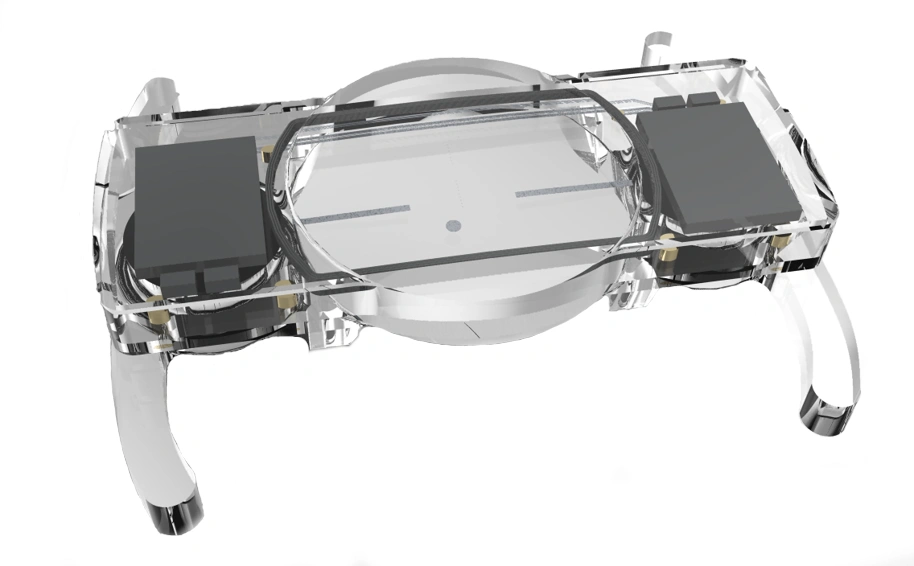

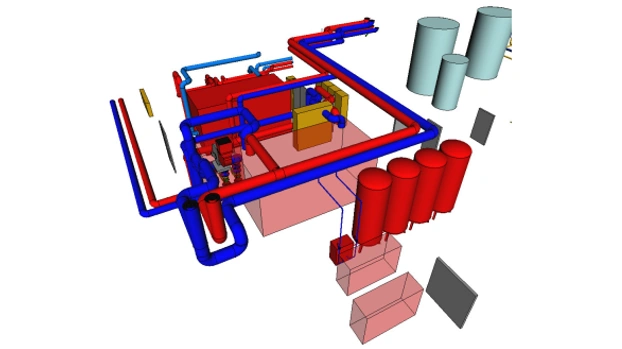

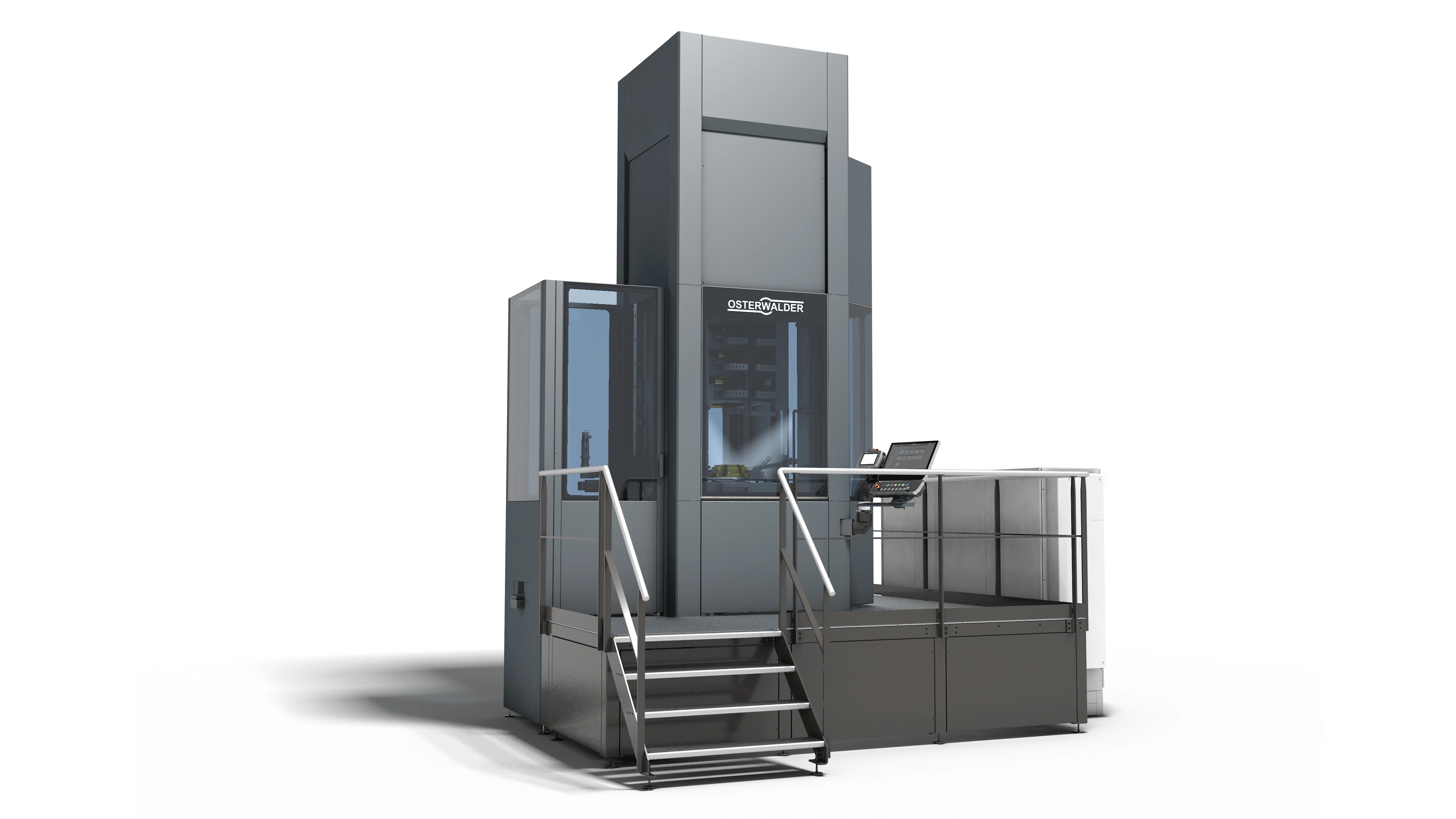

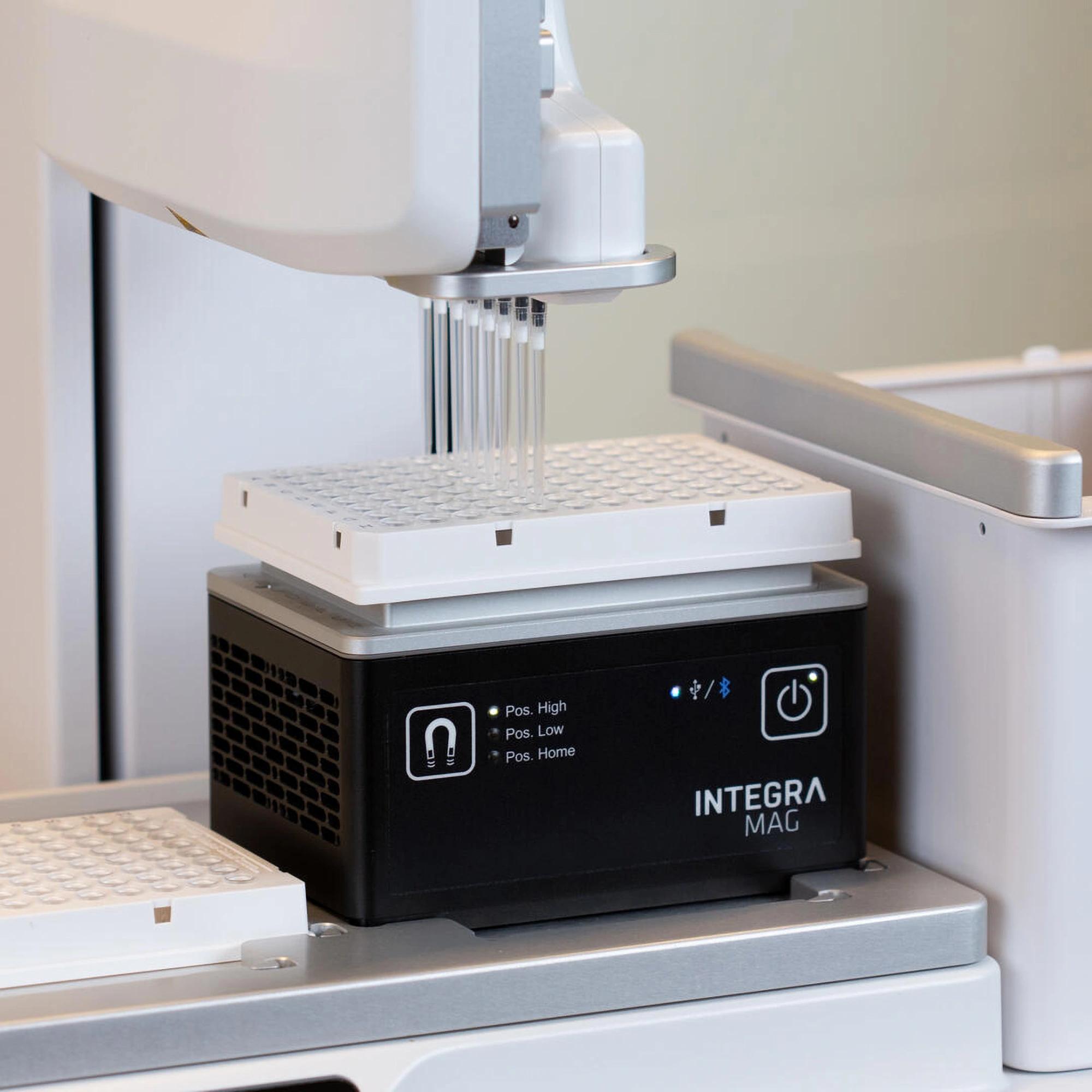

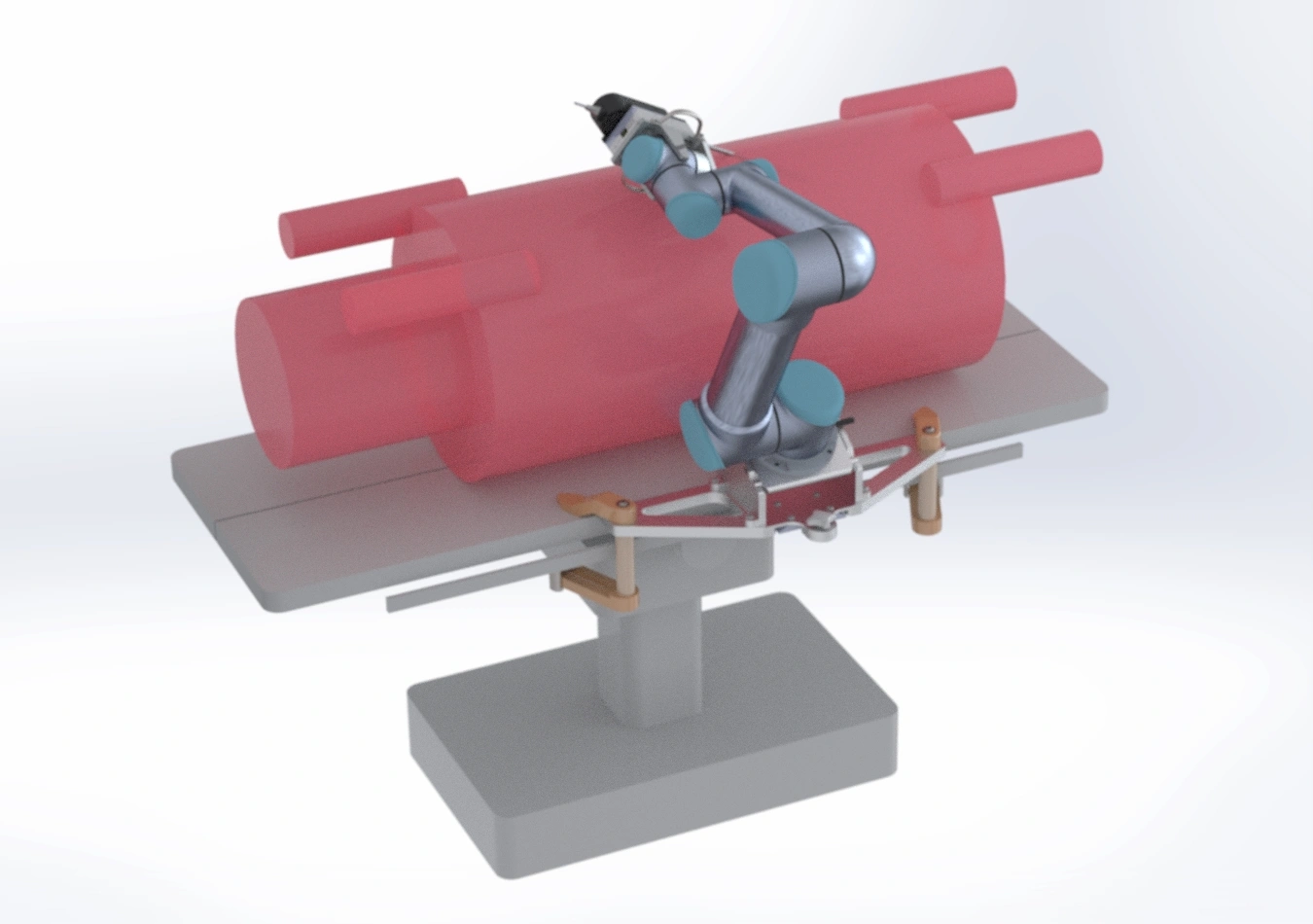

Surrogate Robotic Arm System

Our client is a world leader in surgical tools, engaged in developing a new suite of robotic instruments for a state-of-the-art robotic system.

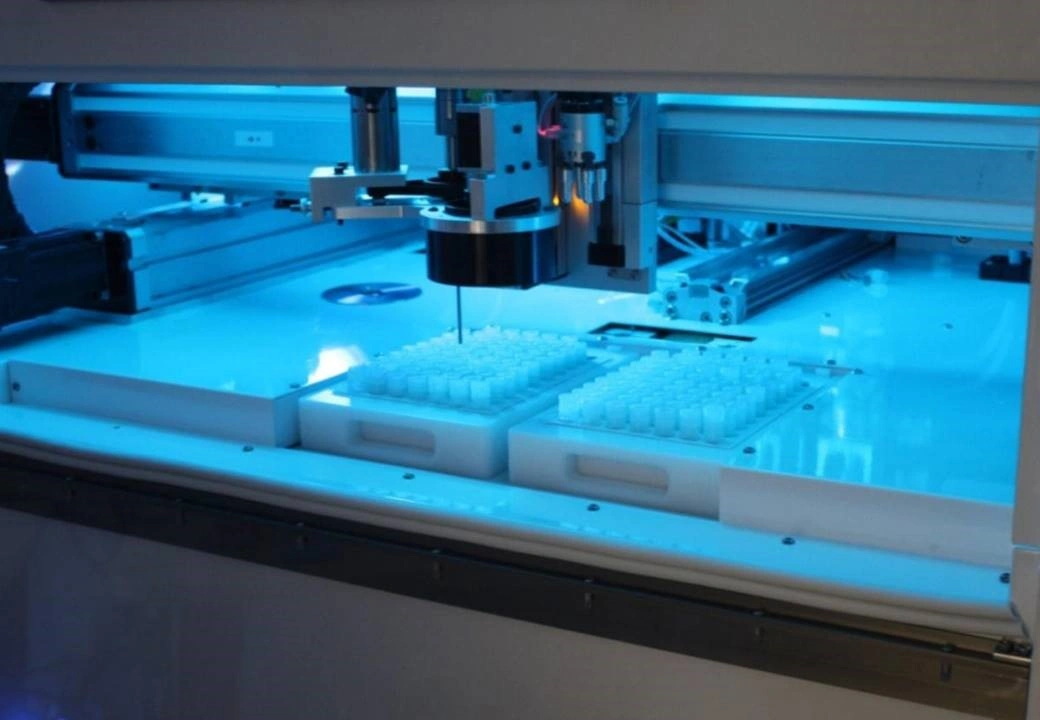

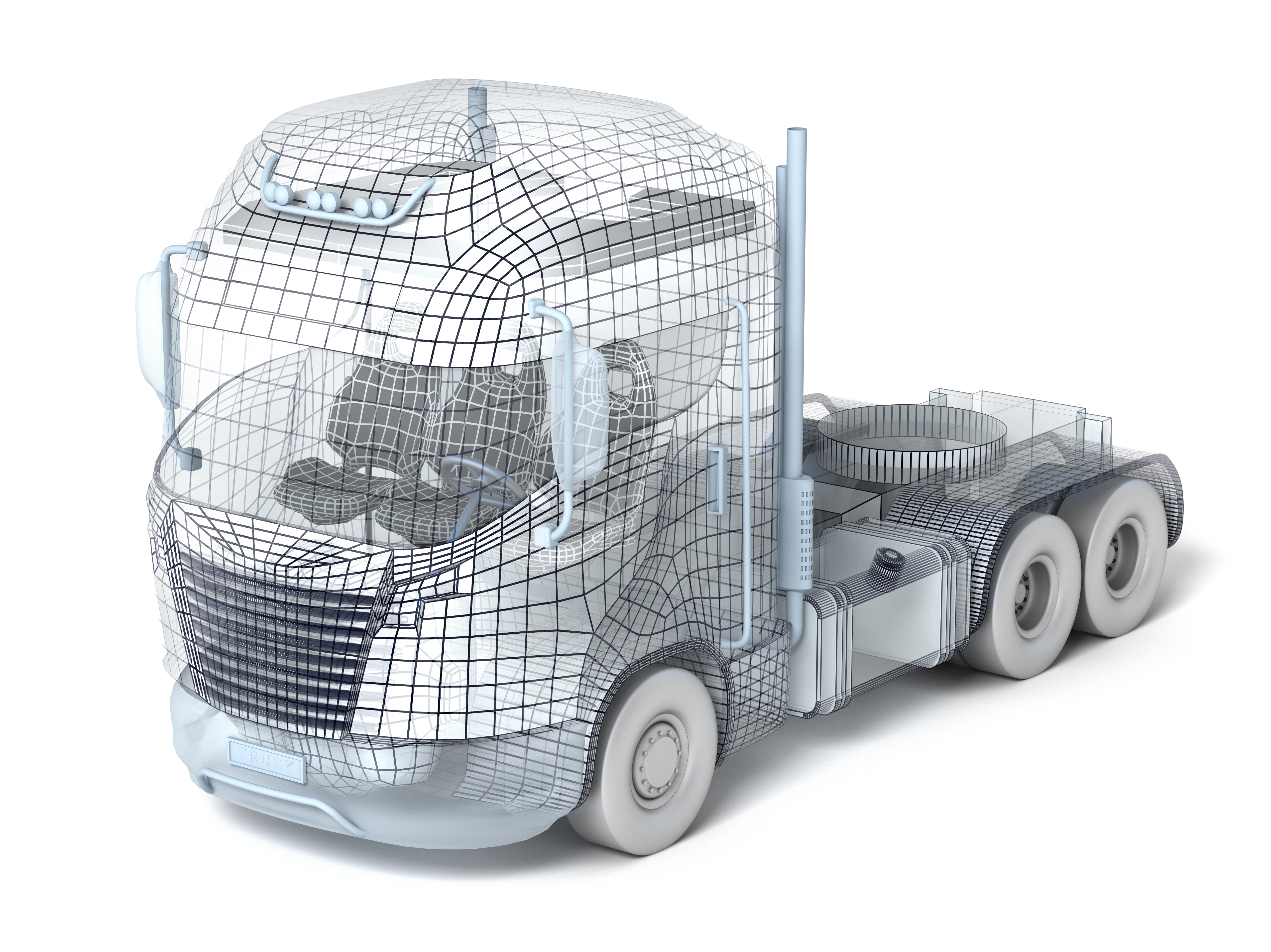

We were tasked to develop and build a “surrogate” robotic arm system, which allows our client to quantify the performance of new instruments comprehensively in a pre-clinical environment. The instruments were tested with the robotic arm to evaluate their technical performance and usability preferences.

We were tasked to develop and build a “surrogate” robotic arm system, which allows our client to quantify the performance of new instruments comprehensively in a pre-clinical environment. The instruments were tested with the robotic arm to evaluate their technical performance and usability preferences.

Technologies

Key Figures

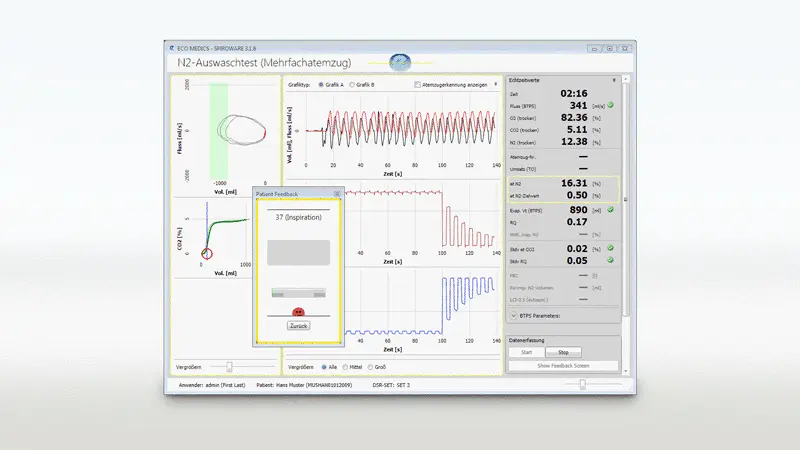

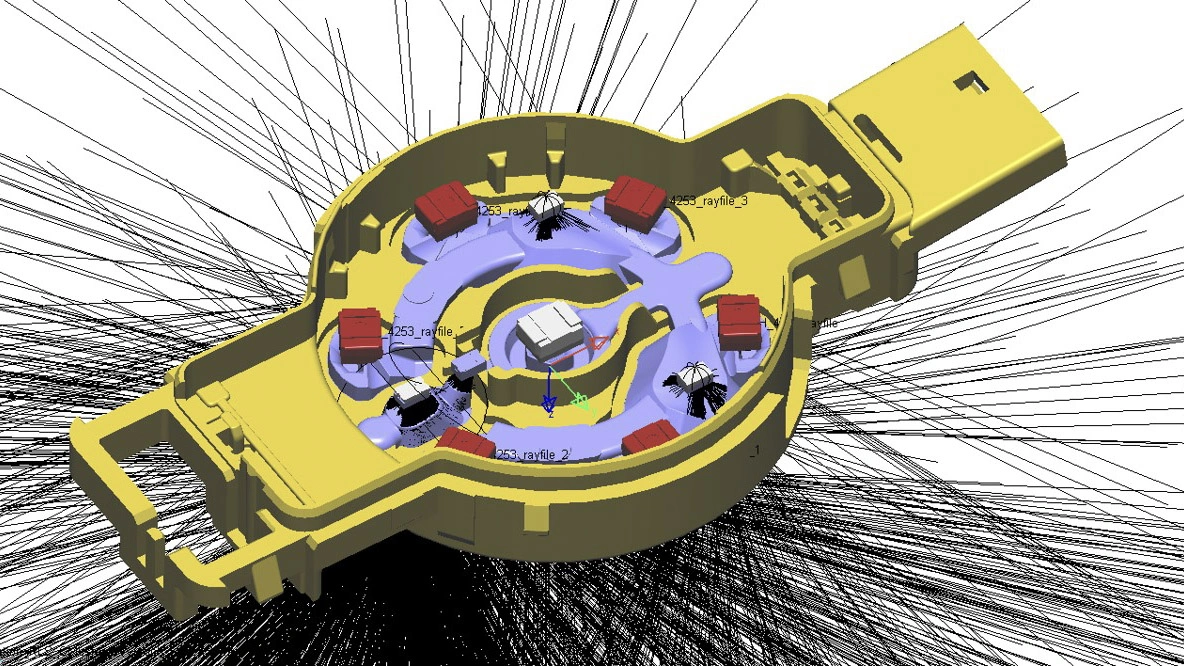

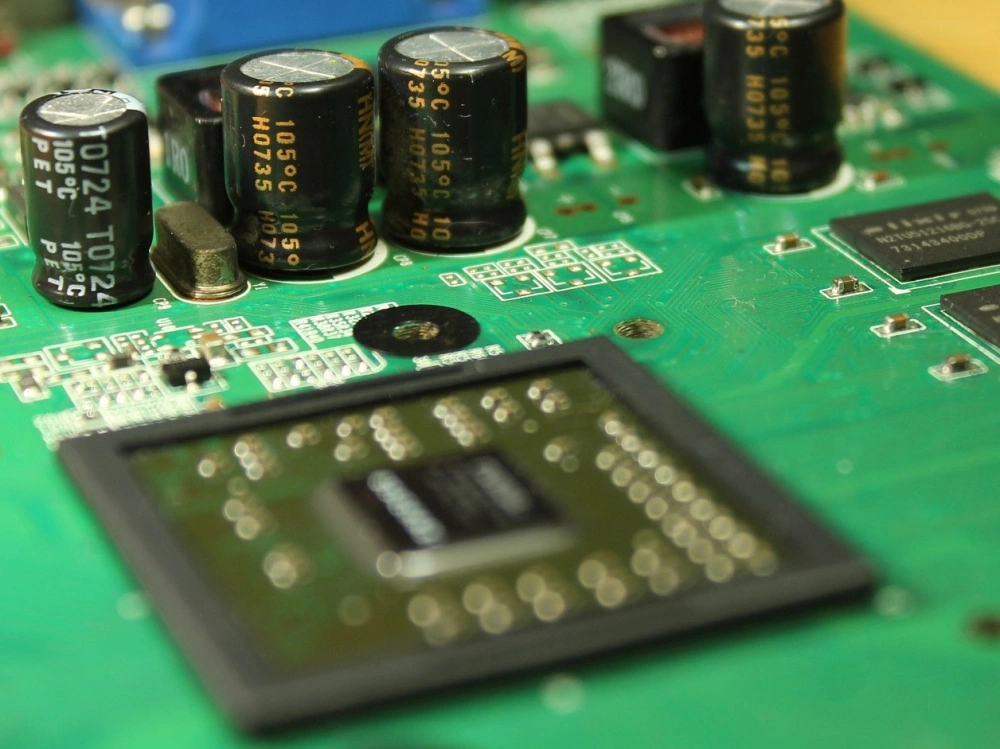

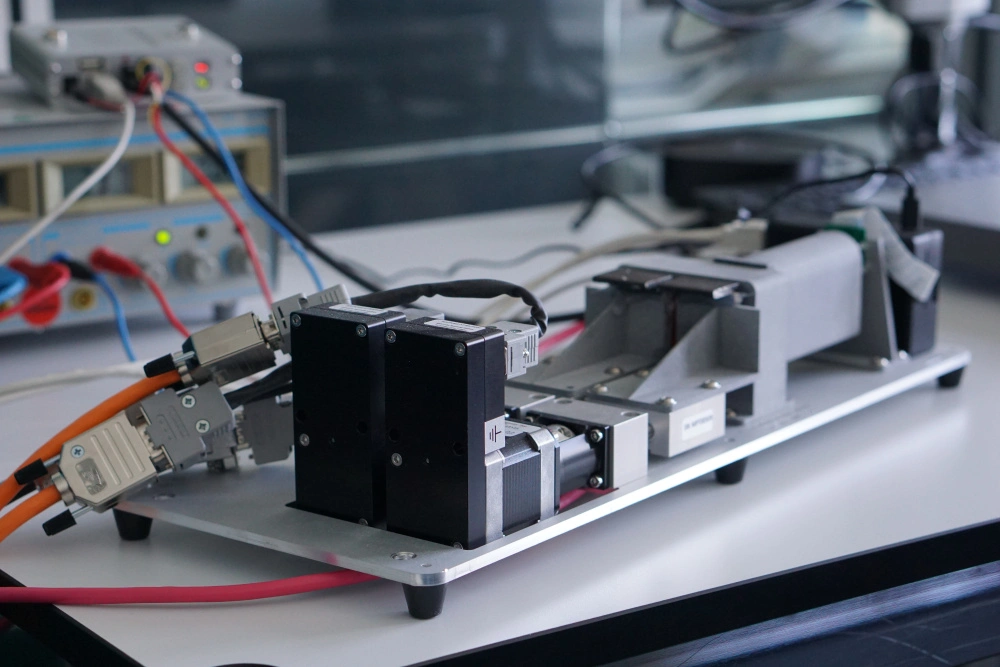

- Integration of off-the-shelf (OTS) robotic arm and hand-held wireless controllers

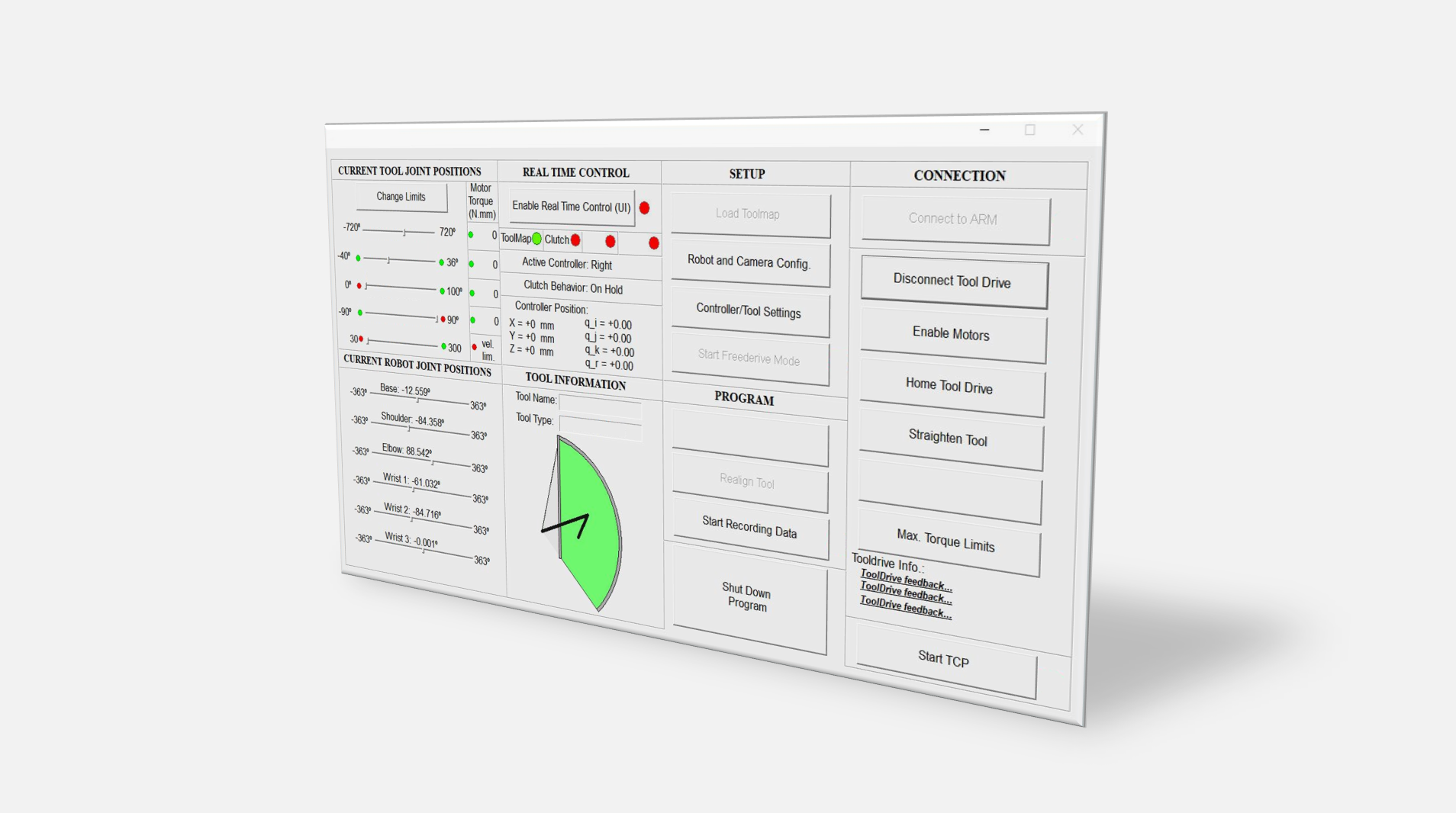

- Lag-free real time control of surgical tool through the UI

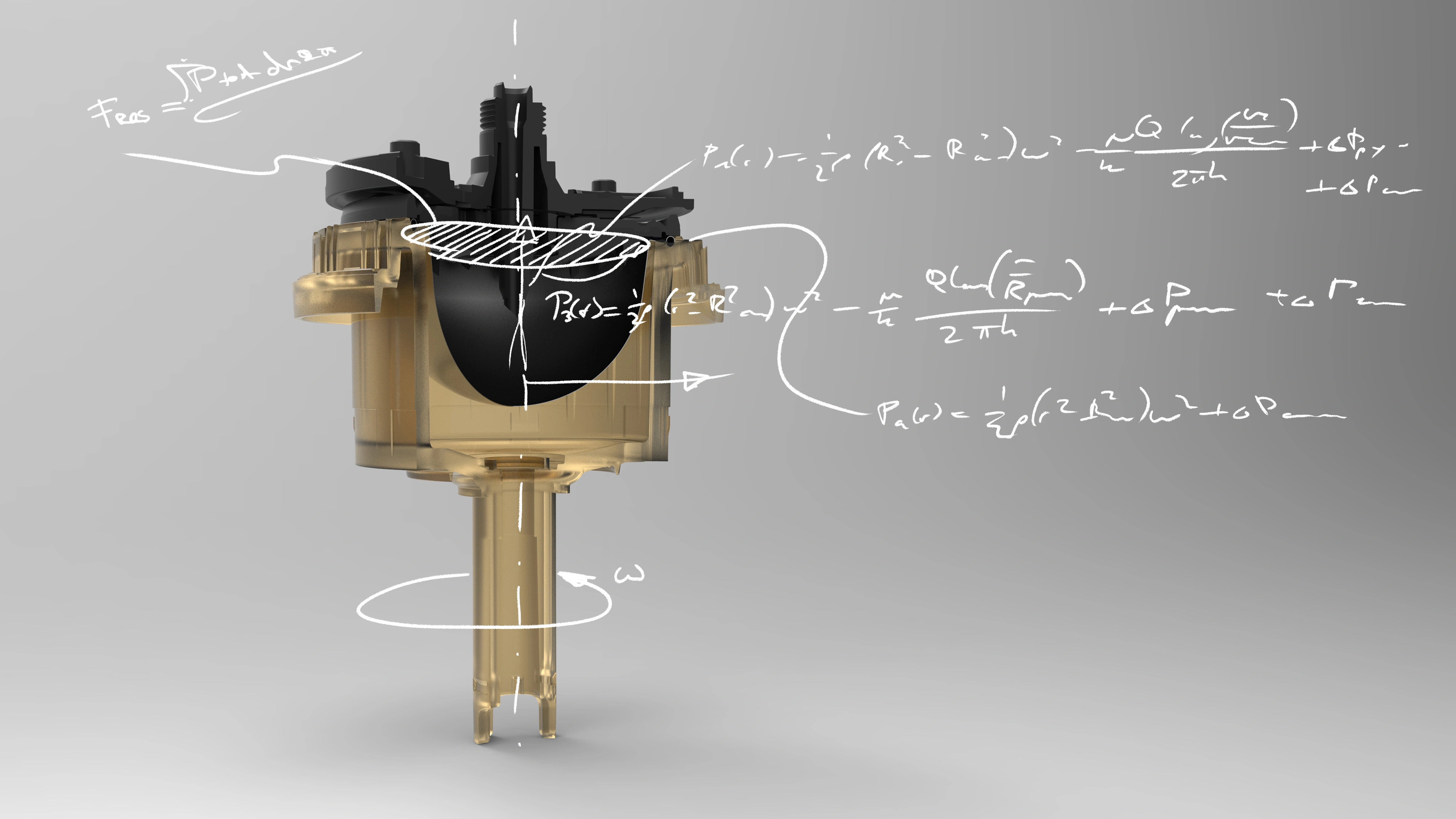

- Iterative and closed form inverse kinematics algorithms of the tool and manipulator

- Core algorithm and GUI developed in visual C++

- Portable system, easy and quick to setup

- Integration of safety features, enabling the system to work in proximity of humans

Our Contribution

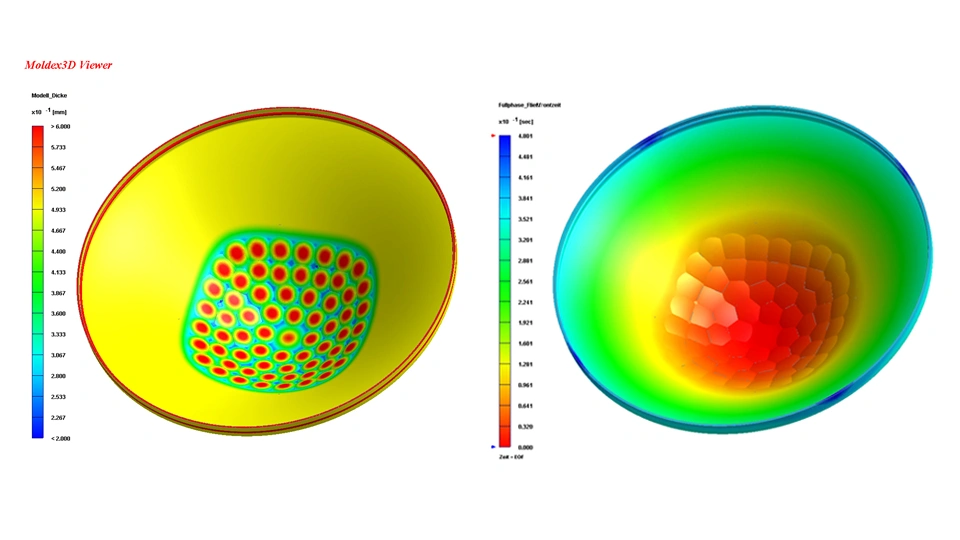

- Develop a system requirements document, the overall conceptual design and the system-level layout

- Identify, select and source OTS components for robotic arm and UI

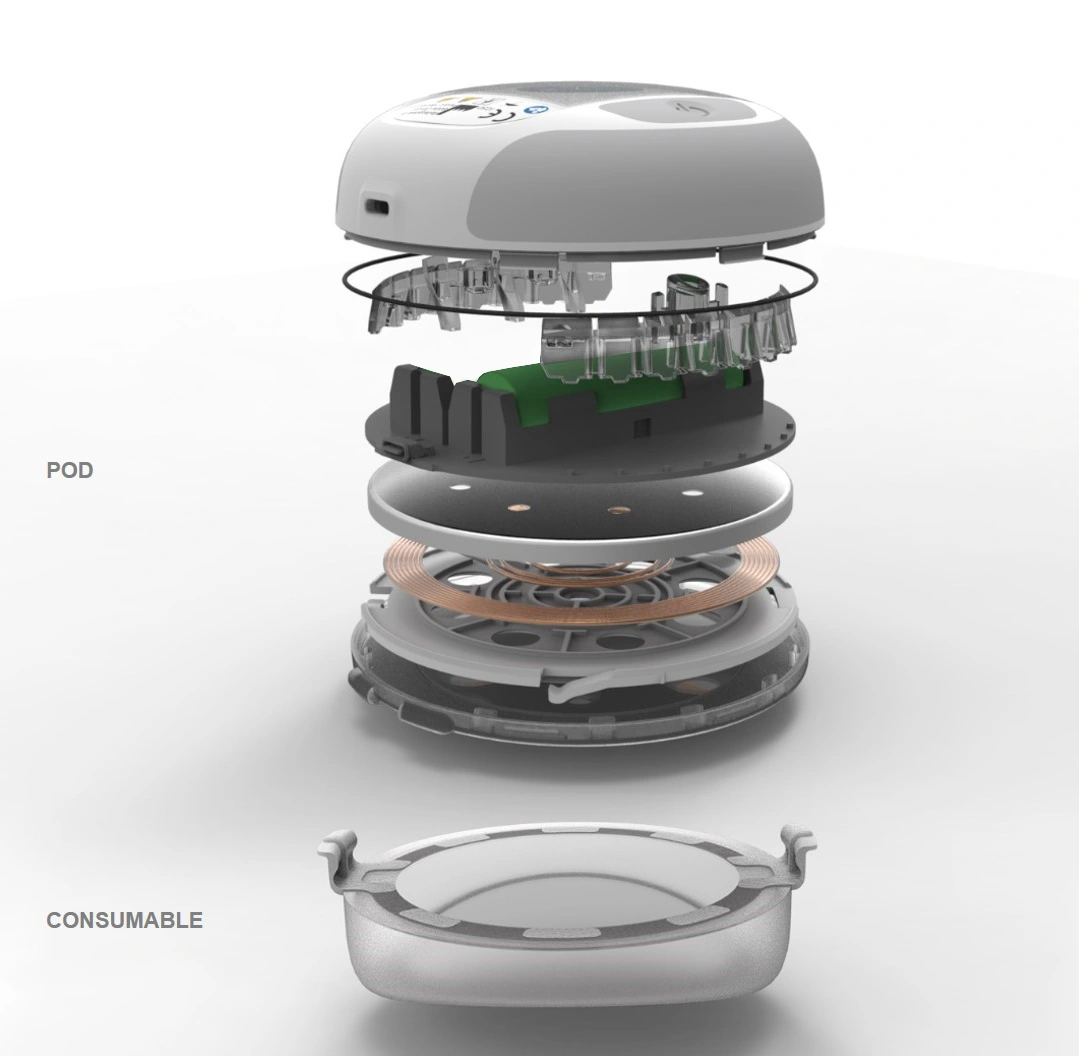

- Custom instrument tool driver electro-mechanical design

- Develop a robust inverse kinematics algorithm which maps user input to tool motion and a backlash mitigation algorithm

- Design and program a control system with a GUI

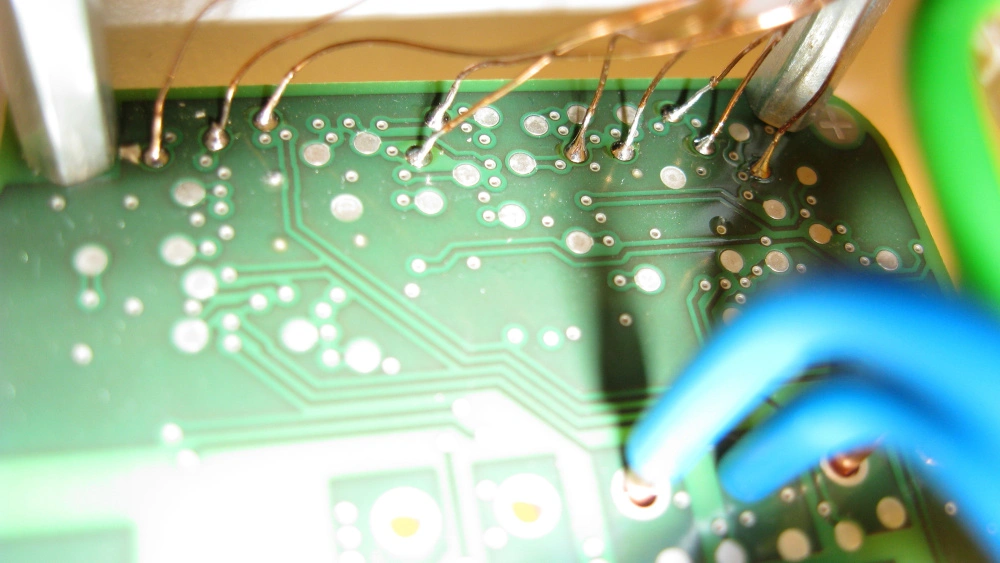

- Assembly, wiring and integration of all subsystems

- In-house functional testing and debugging of entire system

- Engineering support during in-vivo cadaver studies

Outcome

By developing, building and testing a fully functional “surrogate” robotic arm system in record time, our customer was able to accelerate the instrument development and testing program by months.

Contact

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

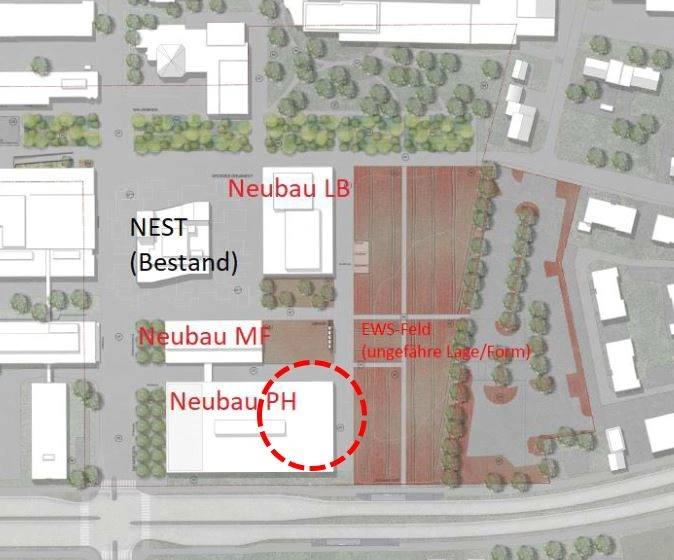

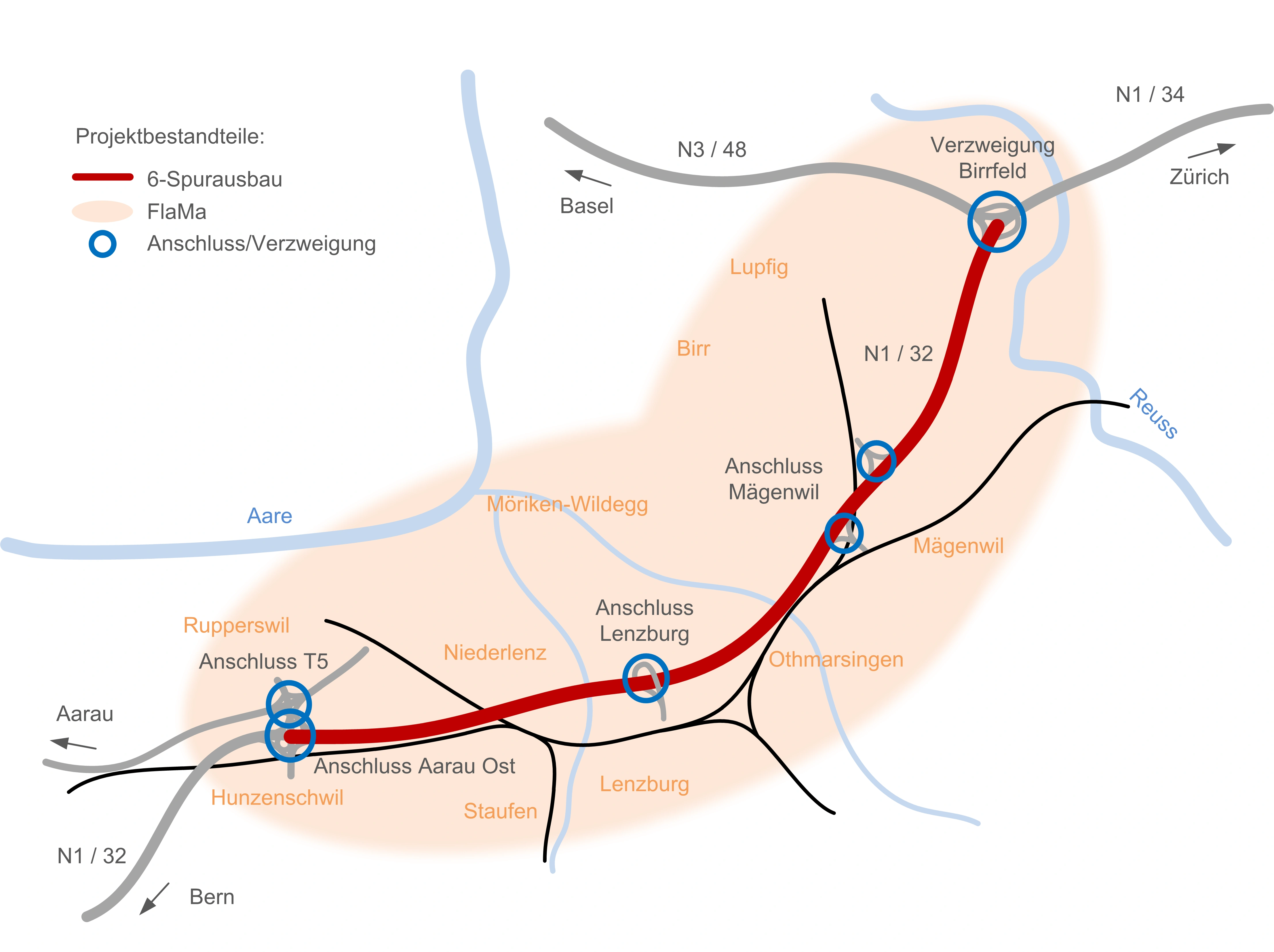

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: