Reference Project

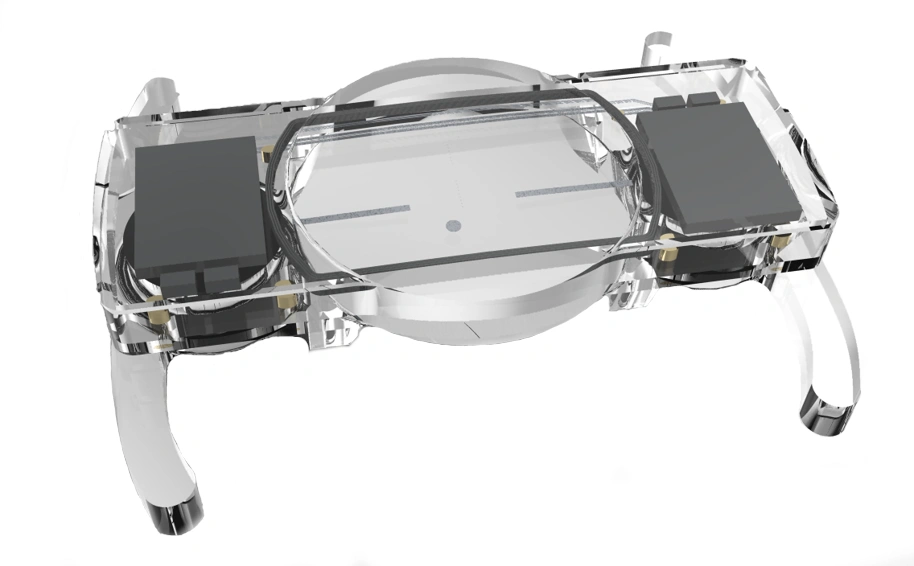

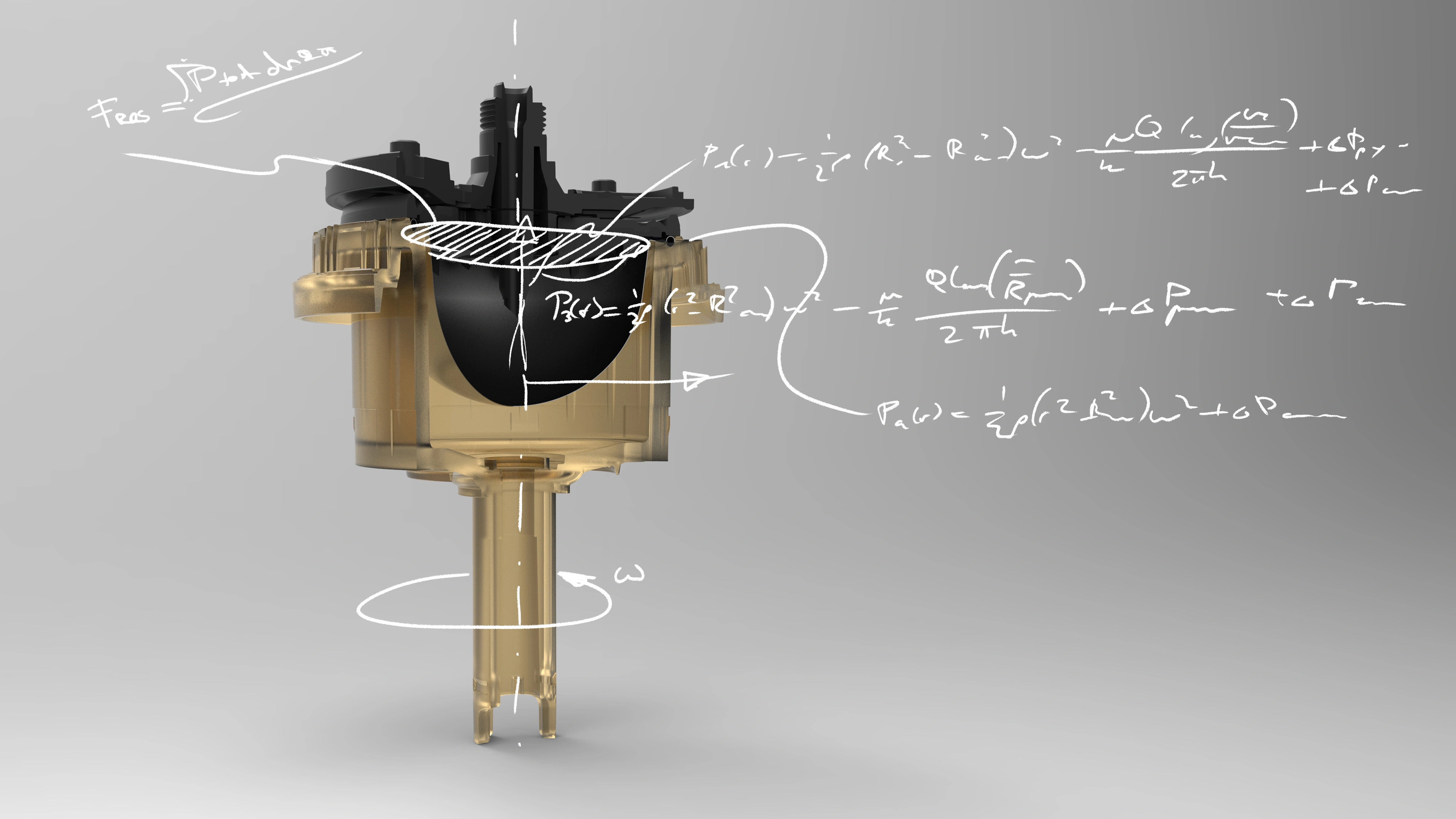

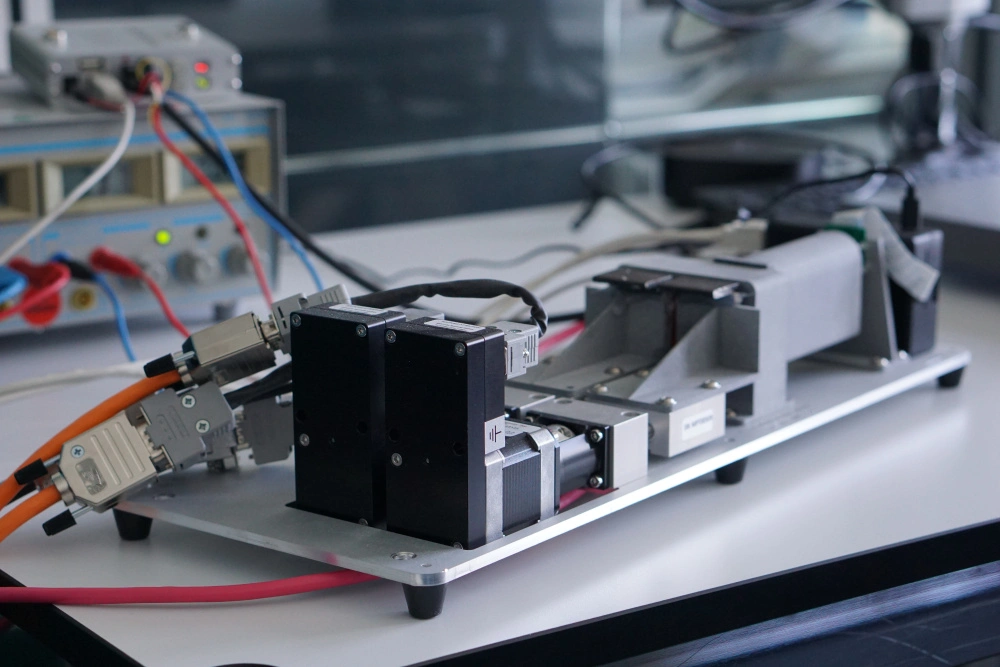

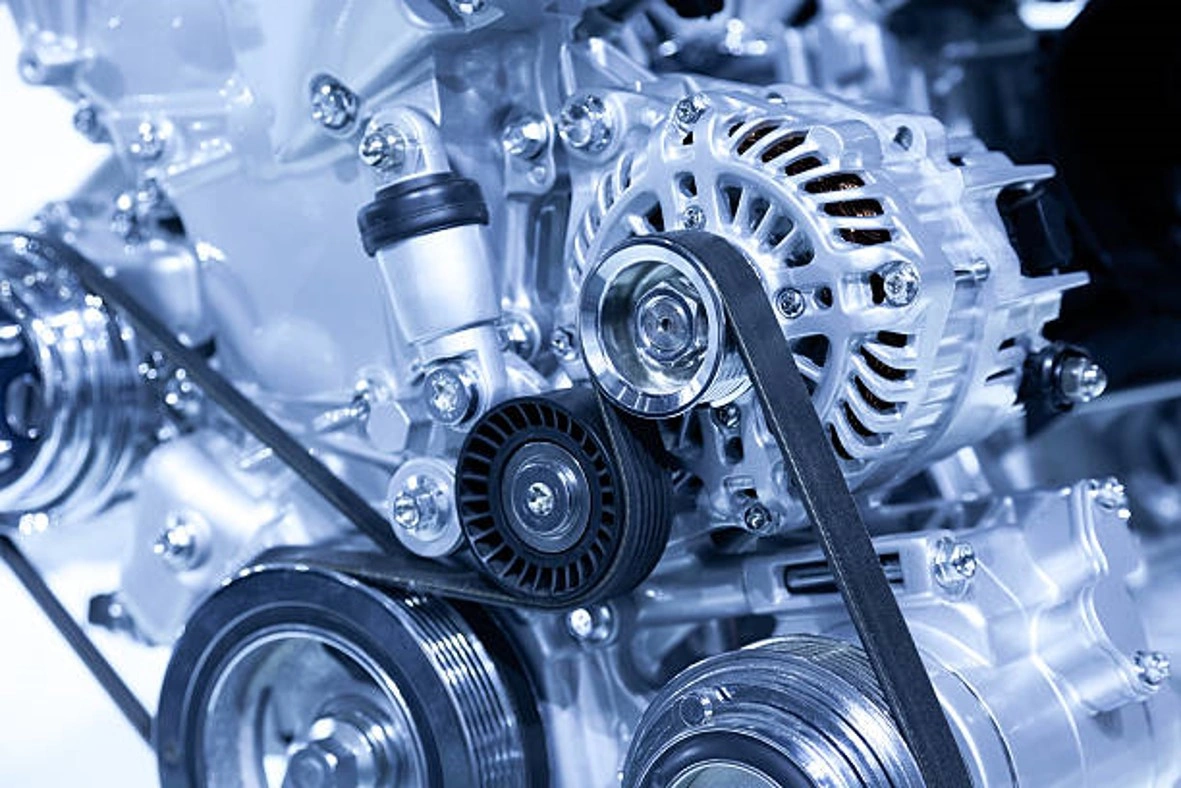

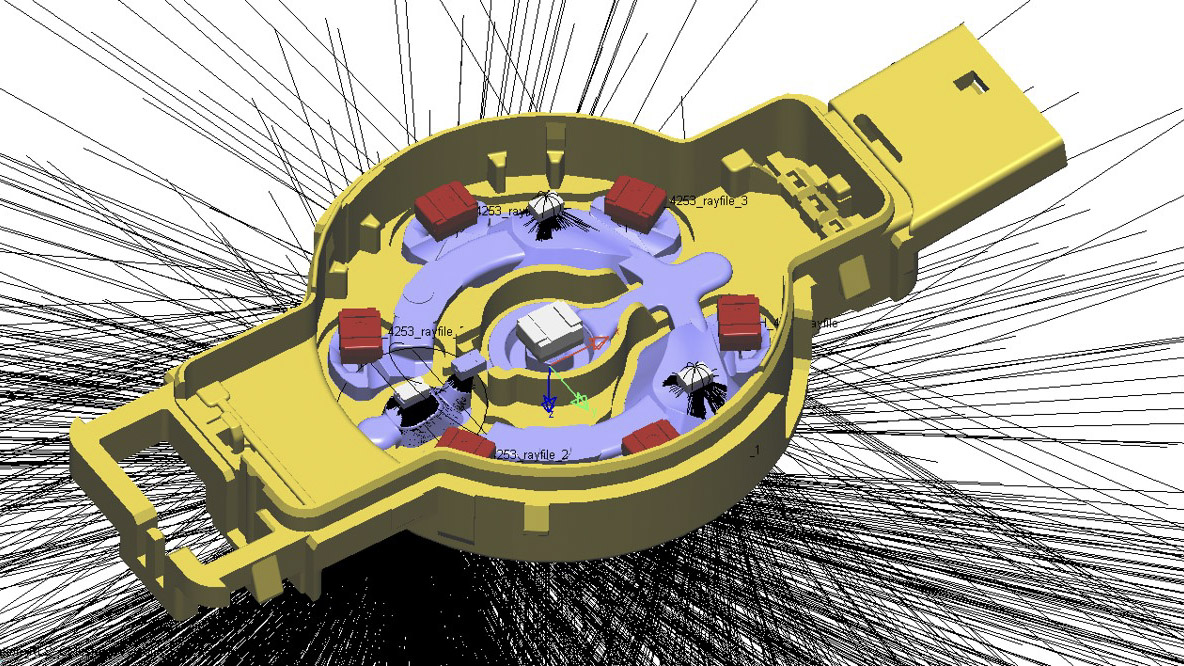

Developing optics for a rain light sensor

The French automotive supplier Vale was looking for a partner to develop the optics for a rain light sensor. The decisive factor in choosing Helbling was the range of competences we have in this area:

solid knowledge and experience in plastic optics for high-volume production (including concept, optics design, optical simulation, optical analyses down to advising on production questions)

experience with cost-down projects (cost reduction)

specific knowledge in the field of optics design

- customizing optical freeform surfaces for an extremely wide- angle sensitivity

characteristic

- analysis and reduction of scattered light

- optical design with LightTools and high performance computing

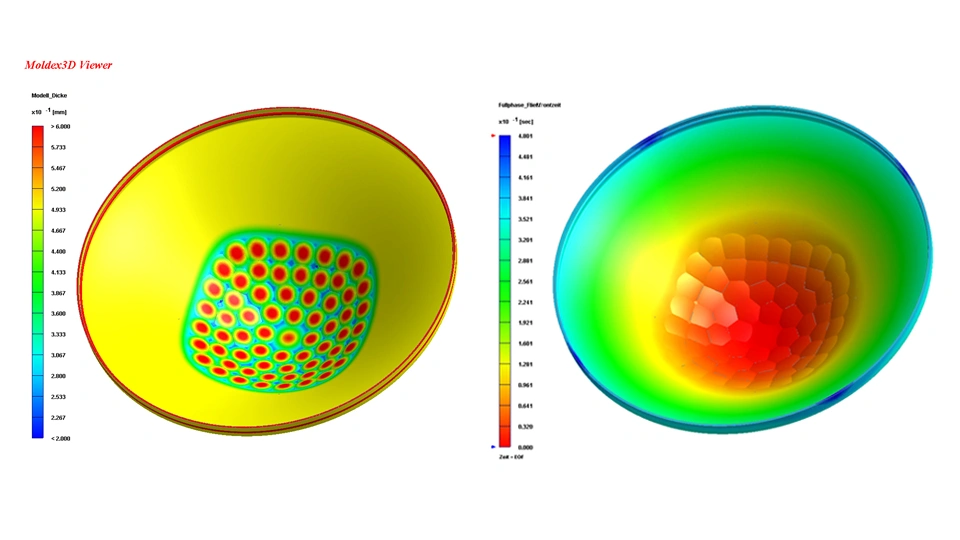

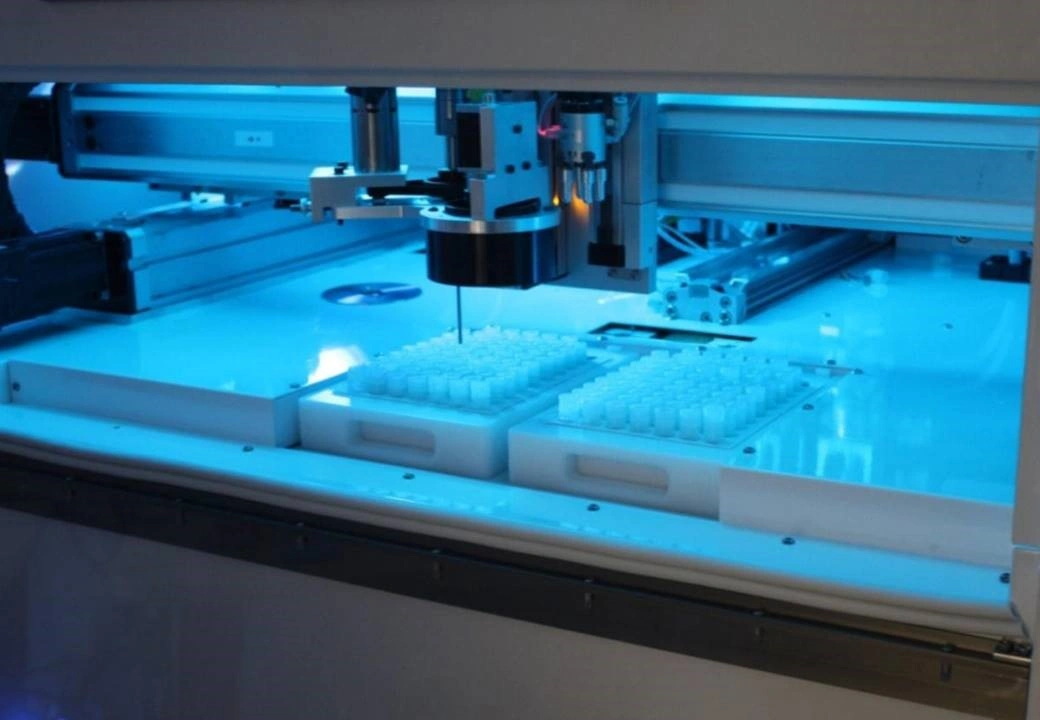

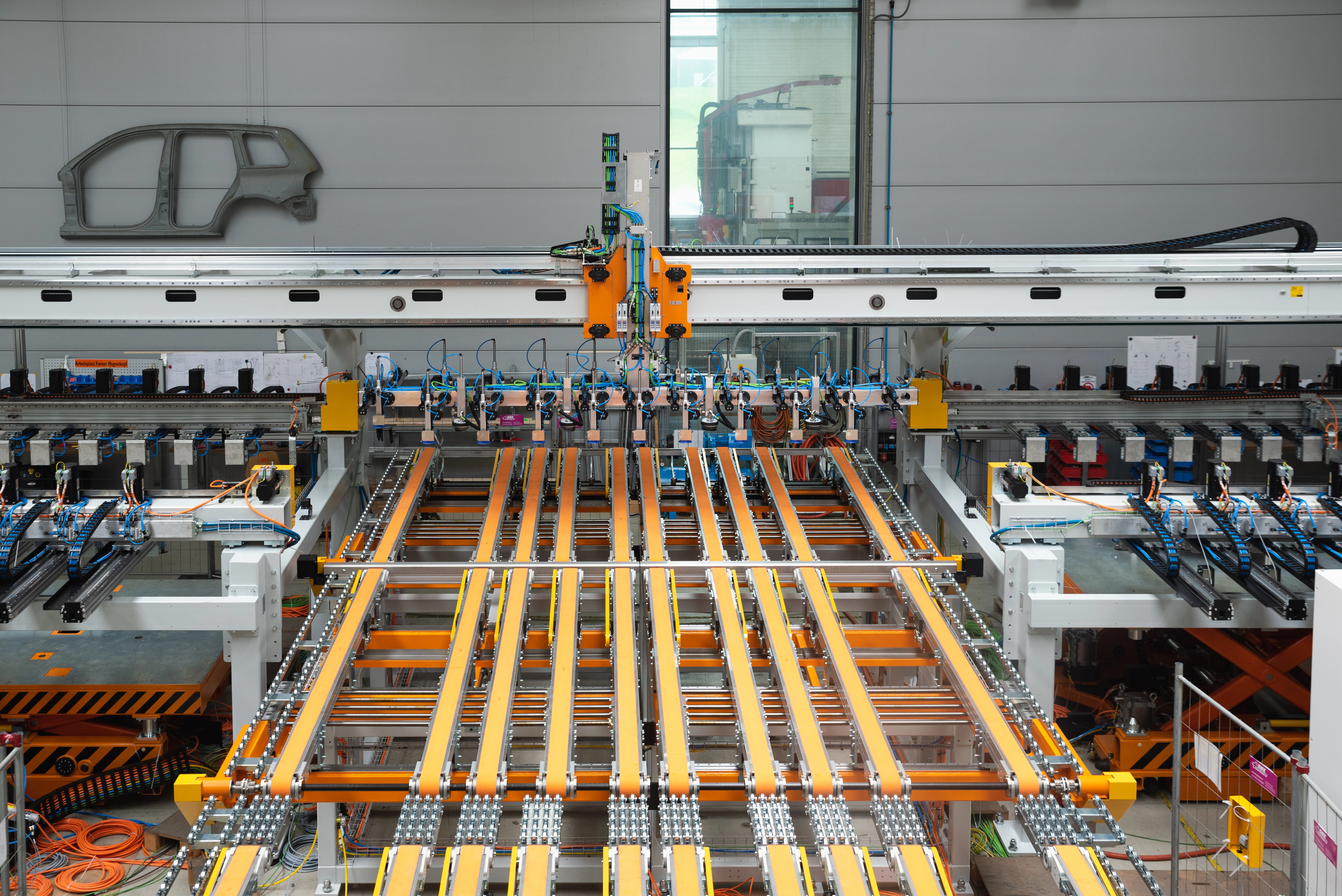

optimizing suitability for injection moulding and mass production (several million/year), reducing reject rate

evaluation of optoelectronic components

solid knowledge and experience in plastic optics for high-volume production (including concept, optics design, optical simulation, optical analyses down to advising on production questions)

experience with cost-down projects (cost reduction)

specific knowledge in the field of optics design

- customizing optical freeform surfaces for an extremely wide- angle sensitivity

characteristic

- analysis and reduction of scattered light

- optical design with LightTools and high performance computing

optimizing suitability for injection moulding and mass production (several million/year), reducing reject rate

evaluation of optoelectronic components

Services

Industries

Technologies

Key Figures

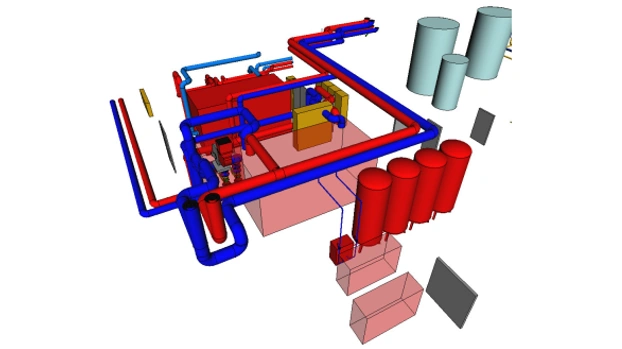

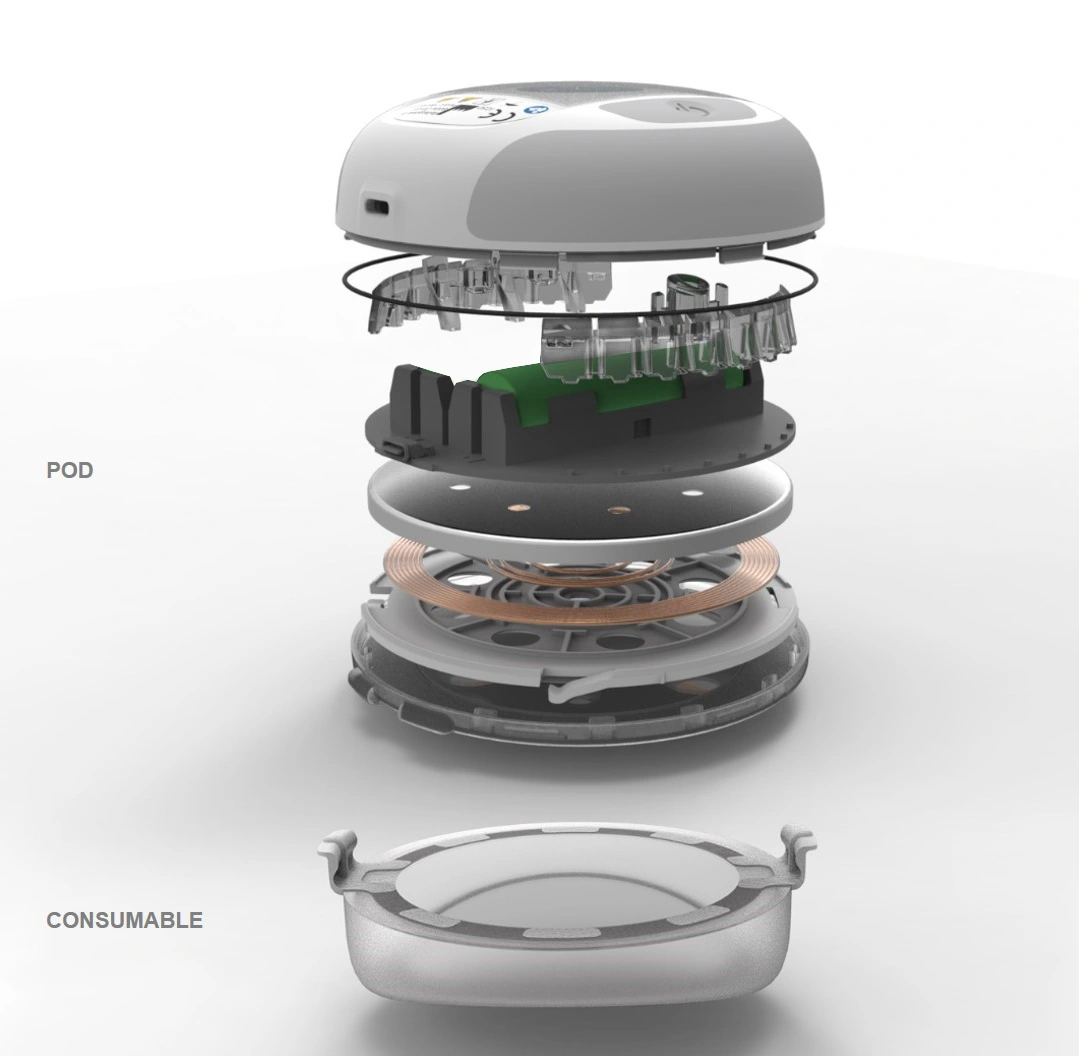

- The rain light sensor combines the following sensor functions:

- rain sensor to identify raindrops on the windshield

- ambient light sensor to measure ambient brightness

- forward sensor to measure brightness ahead of the

vehicle

- solar sensor to measure sun position

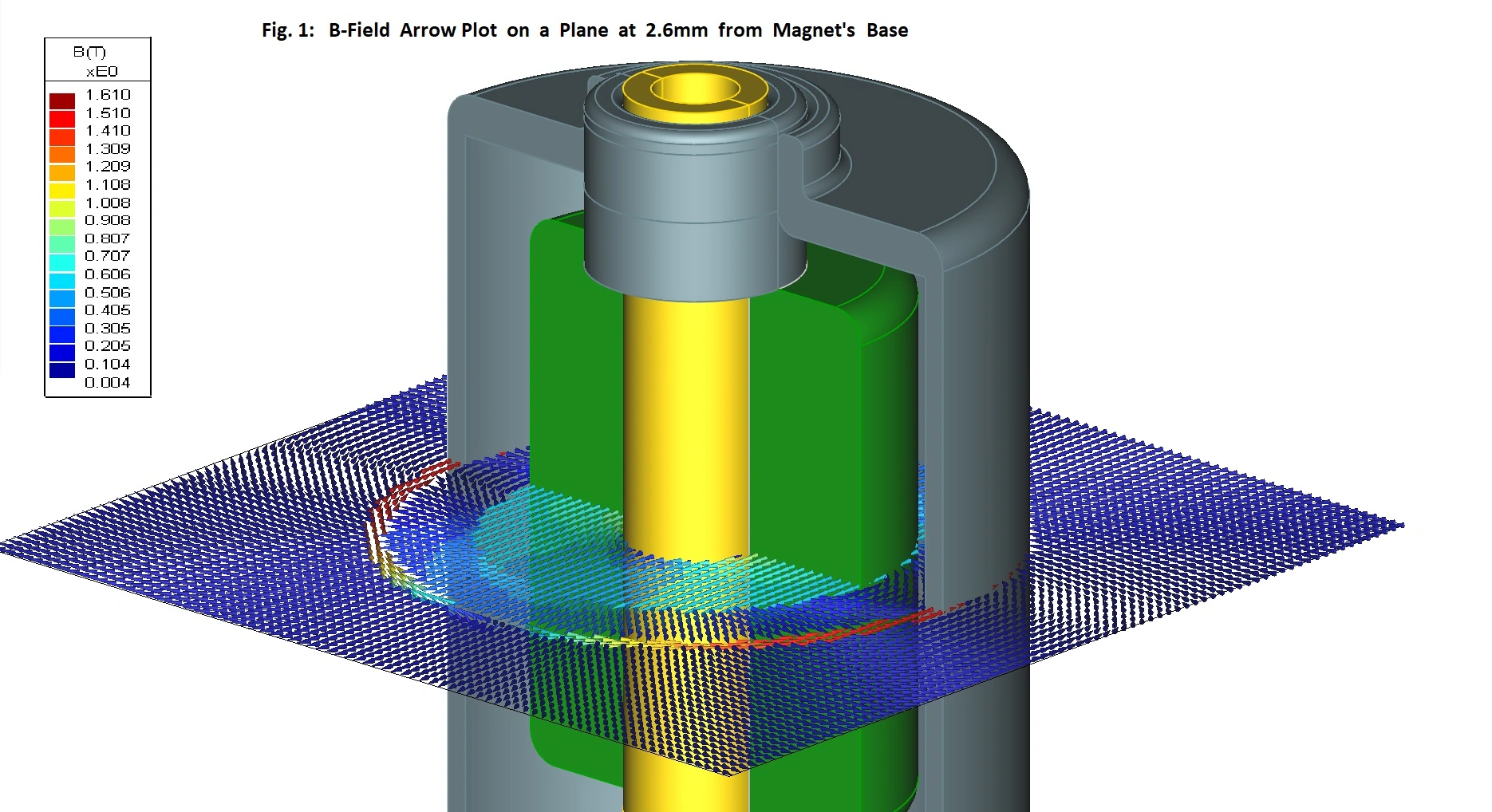

- The optics of all the sensors are integrated into a single component and are implemented with a total of 27 optical surfaces: 5 freeform surfaces, 4 toroidal surfaces, 8 aspherical surfaces, 10 prisms

- The sensor is optimized for series production of several million units/year

- The sensor can be used for all standard types of windshield with a thickness of 3-6 mm

Our Contribution

- Concept development, feasibility analysis

- Design, calculation and optimization of optical surfaces

- Optical simulations, tolerance analysis, scattered light analyses

- Production oriented design of optics in 3D CAD

- The project was handled in several phases:

- concept development

- optical development and calculation

- adaptation of optics to new customer specifications

- industrialization

Outcome

- The sensor is produced in large volumes

- The sensor is installed in Audi and VW vehicles, among others

- A new generation is currently in development

Contact

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

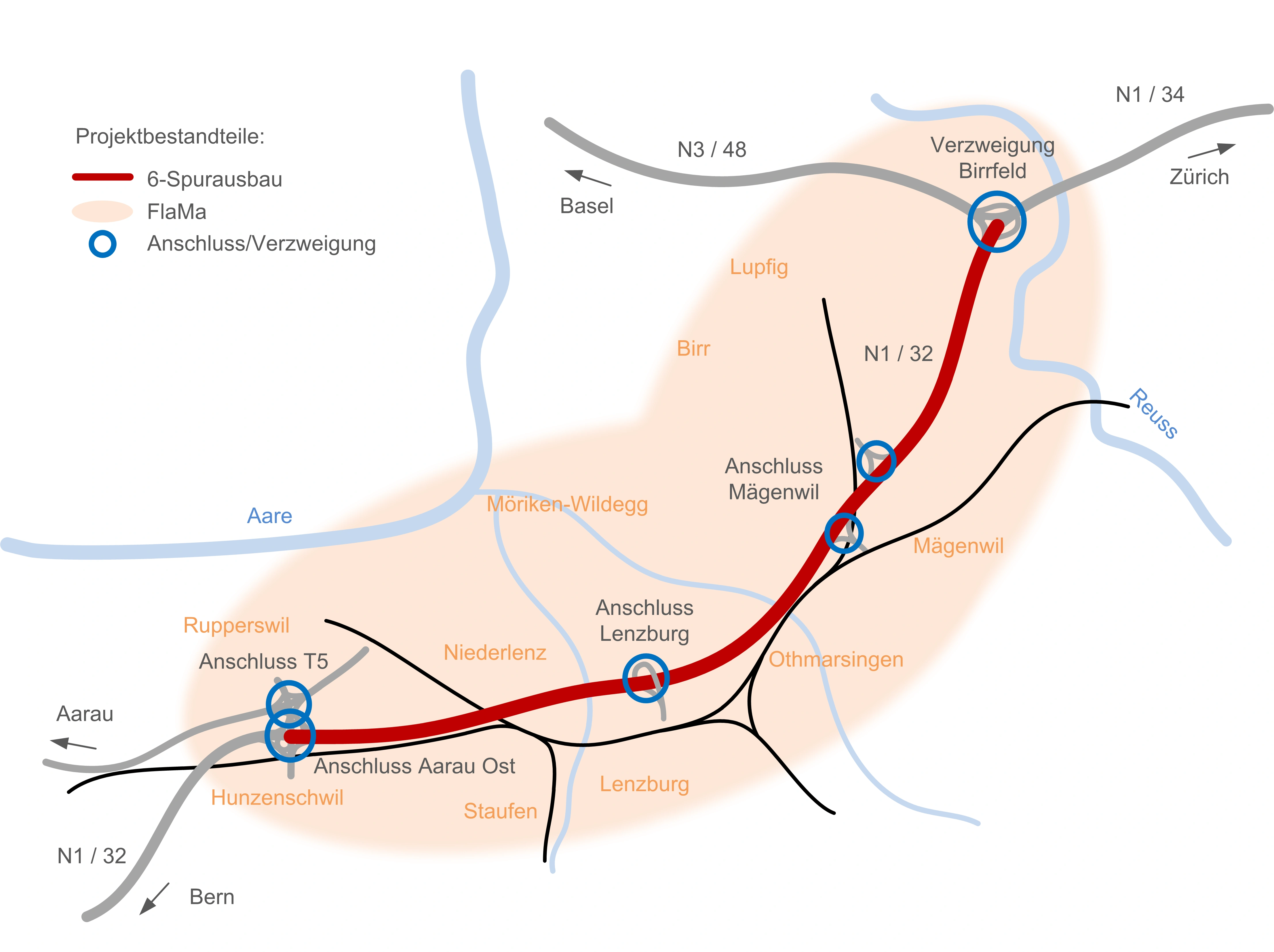

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: