Project

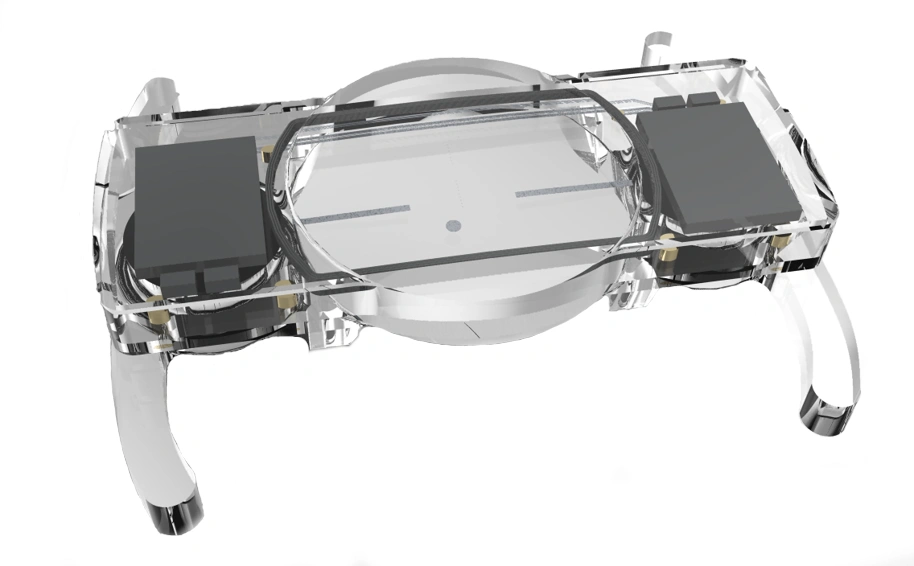

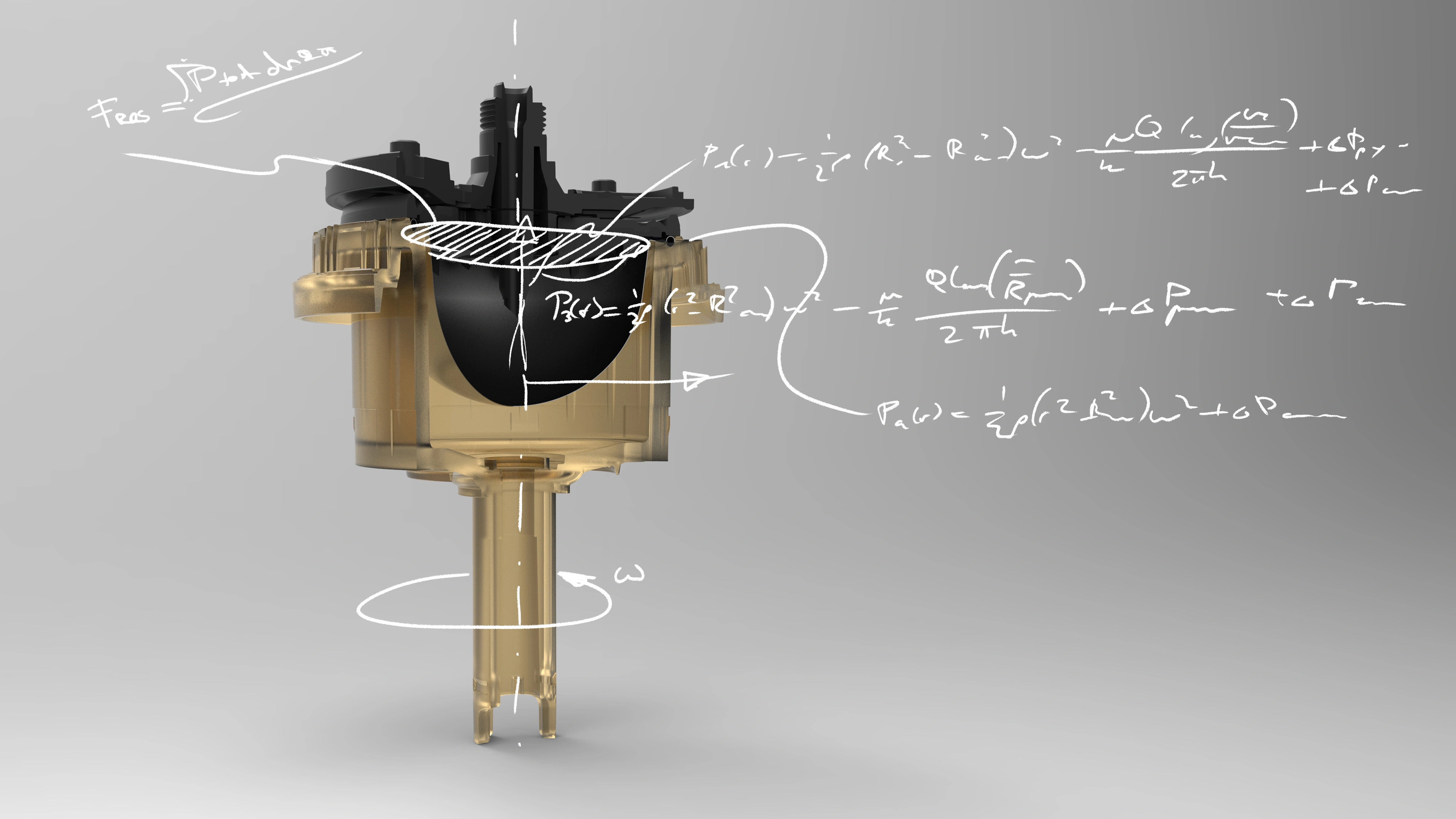

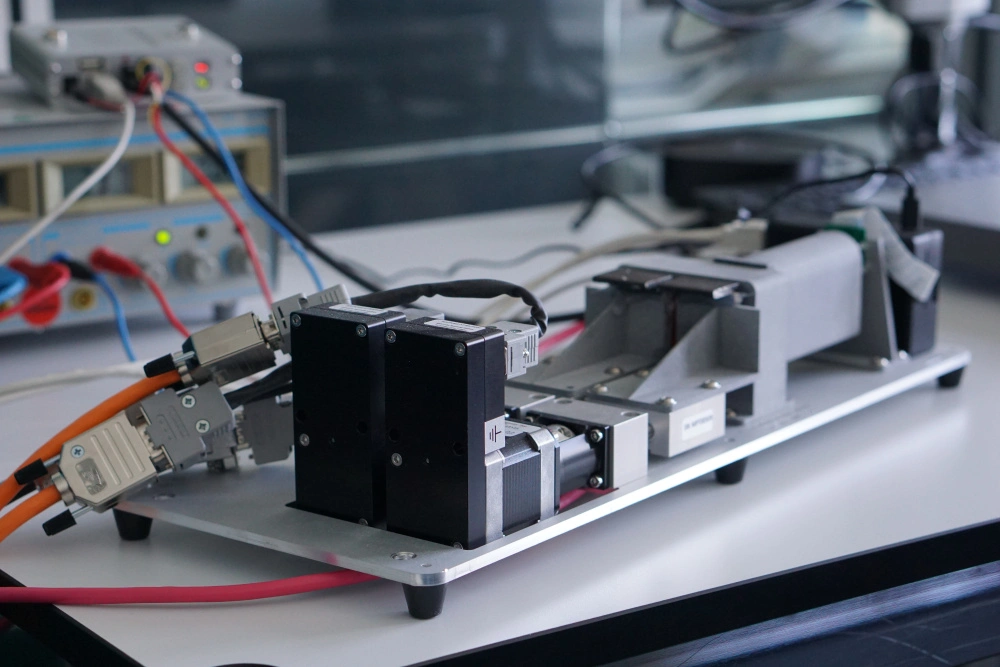

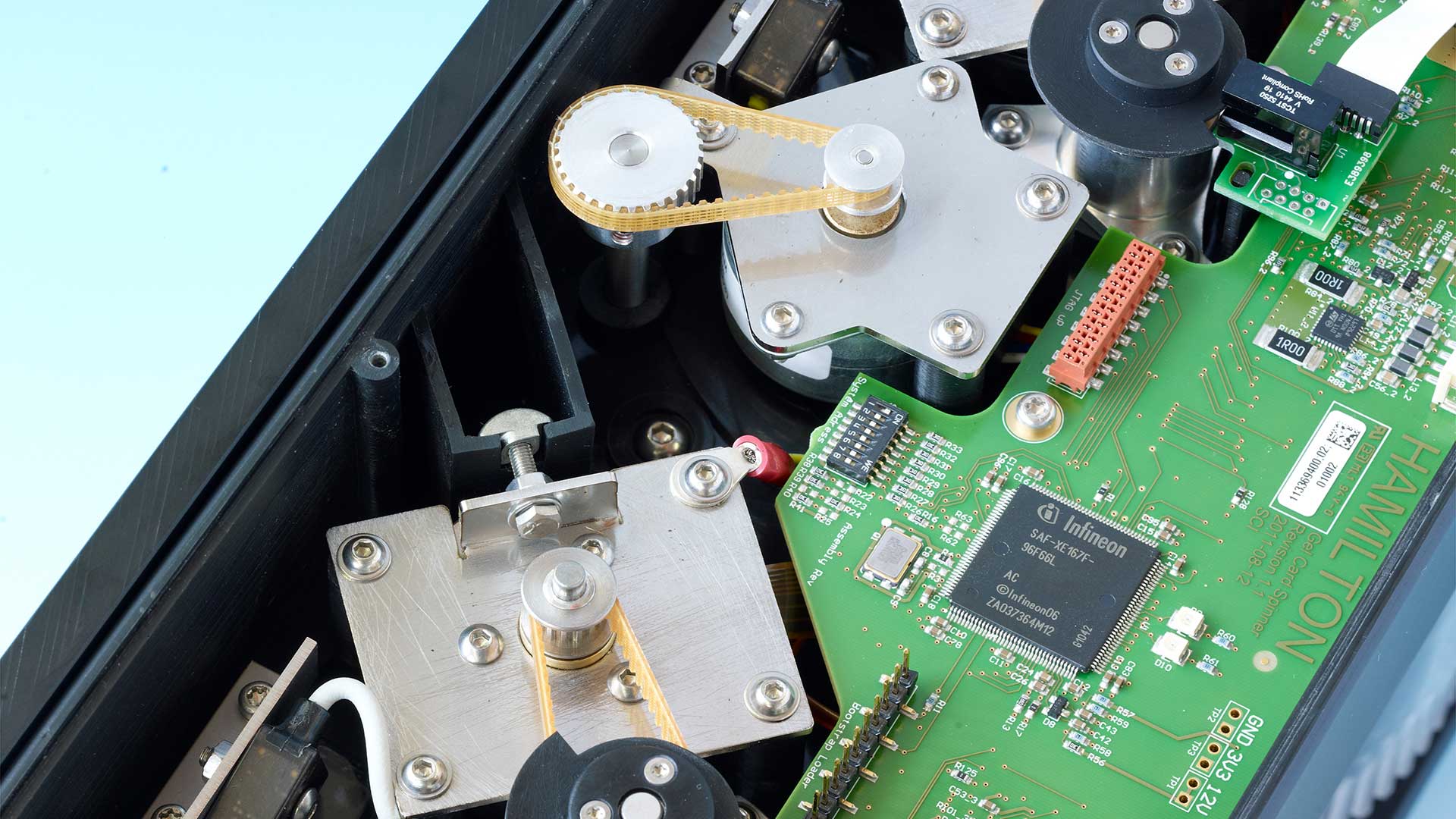

Gel Card Spinner

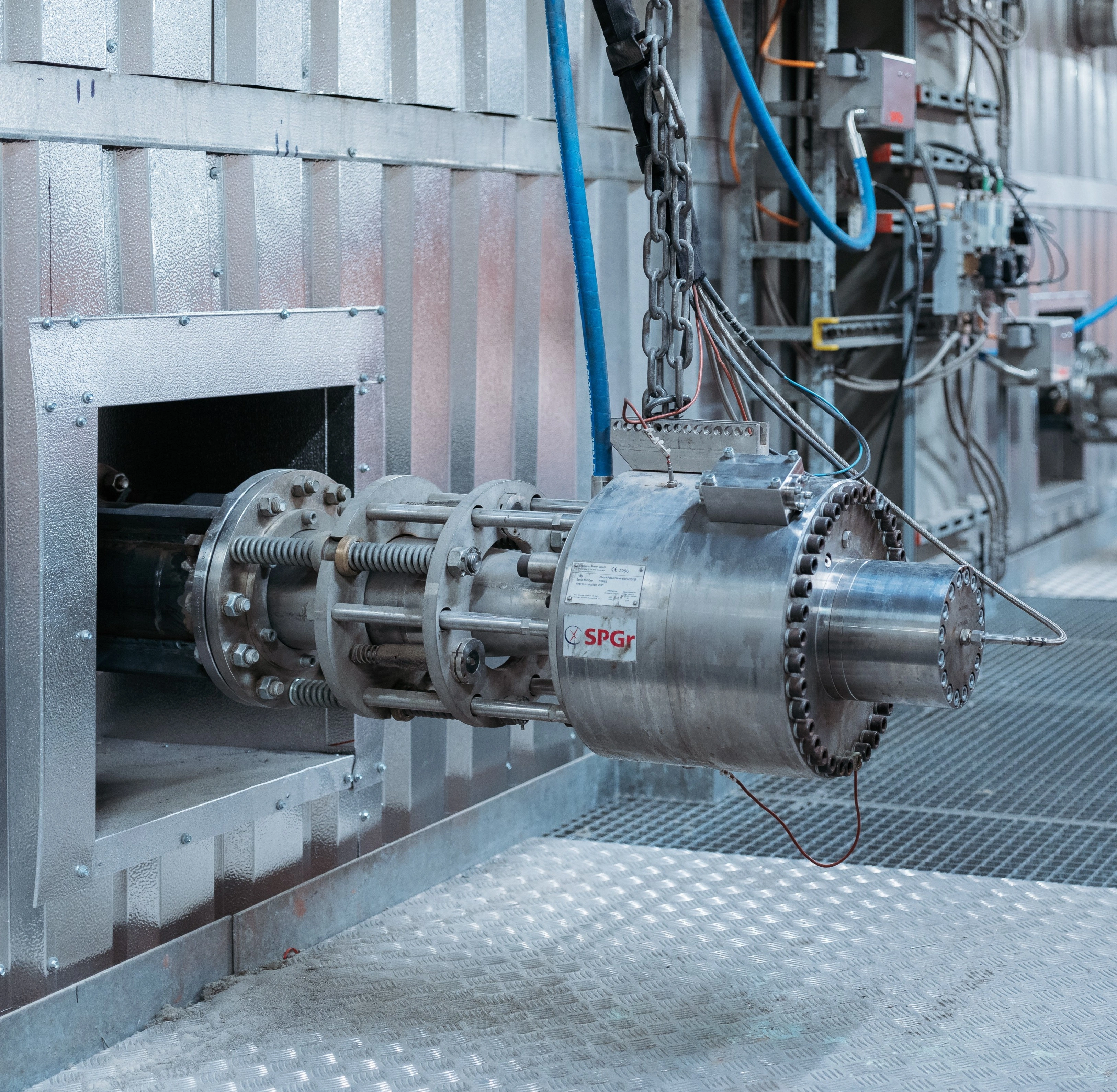

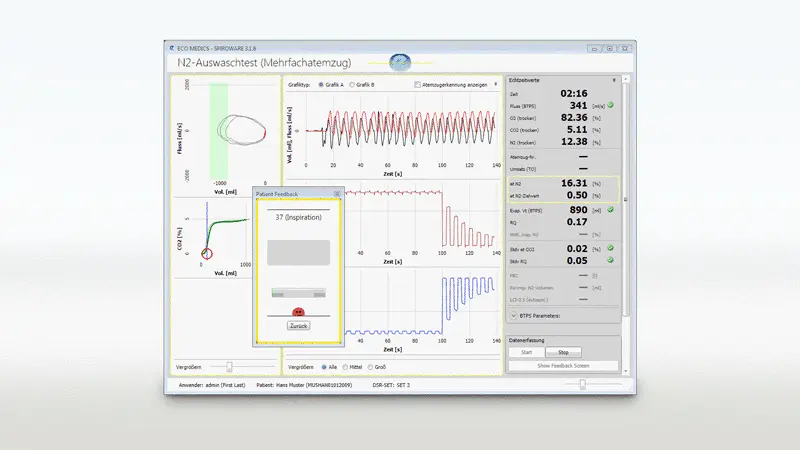

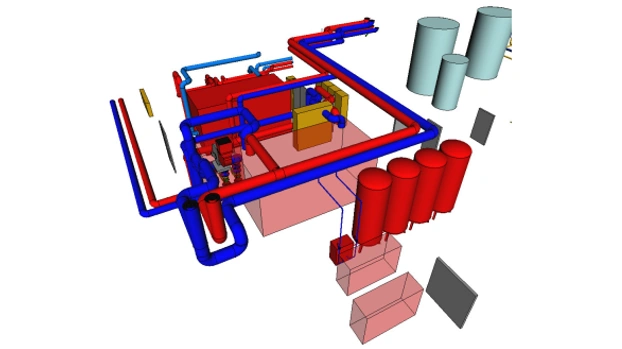

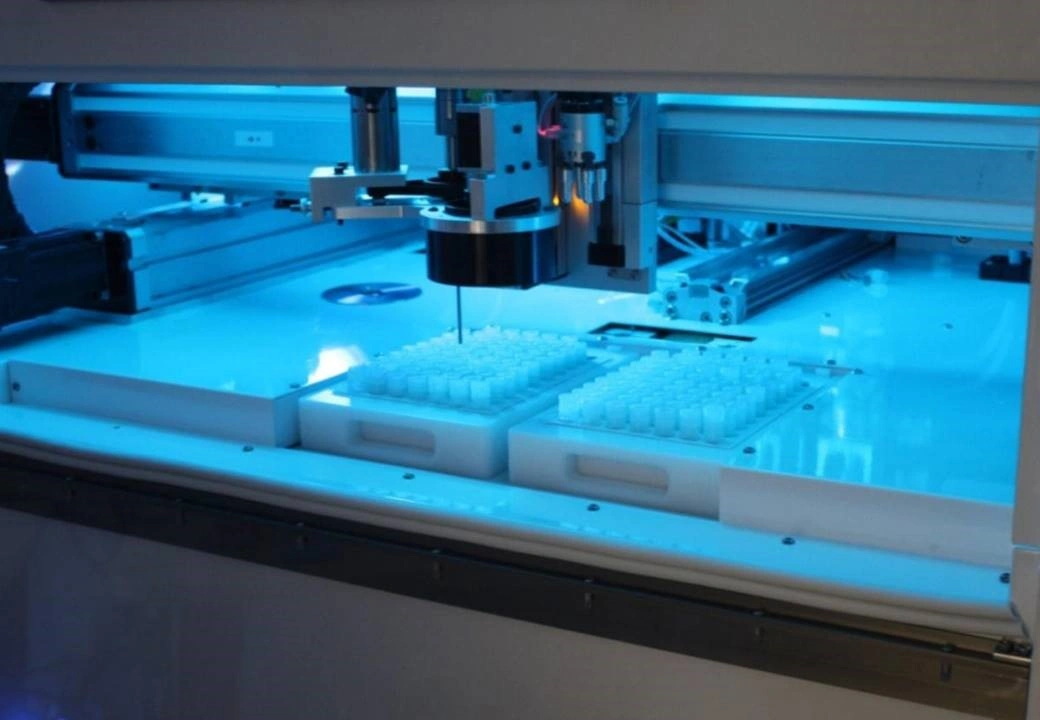

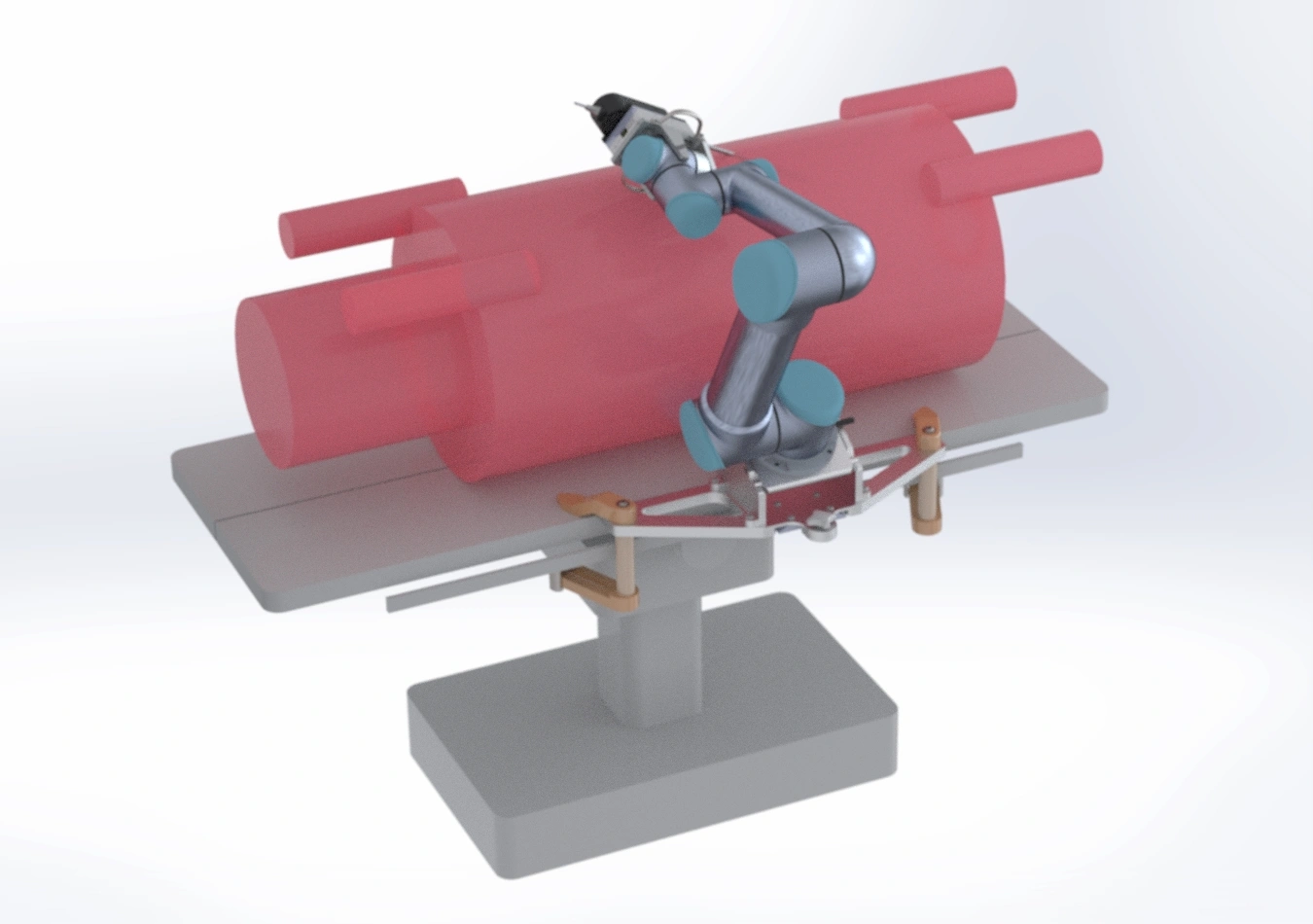

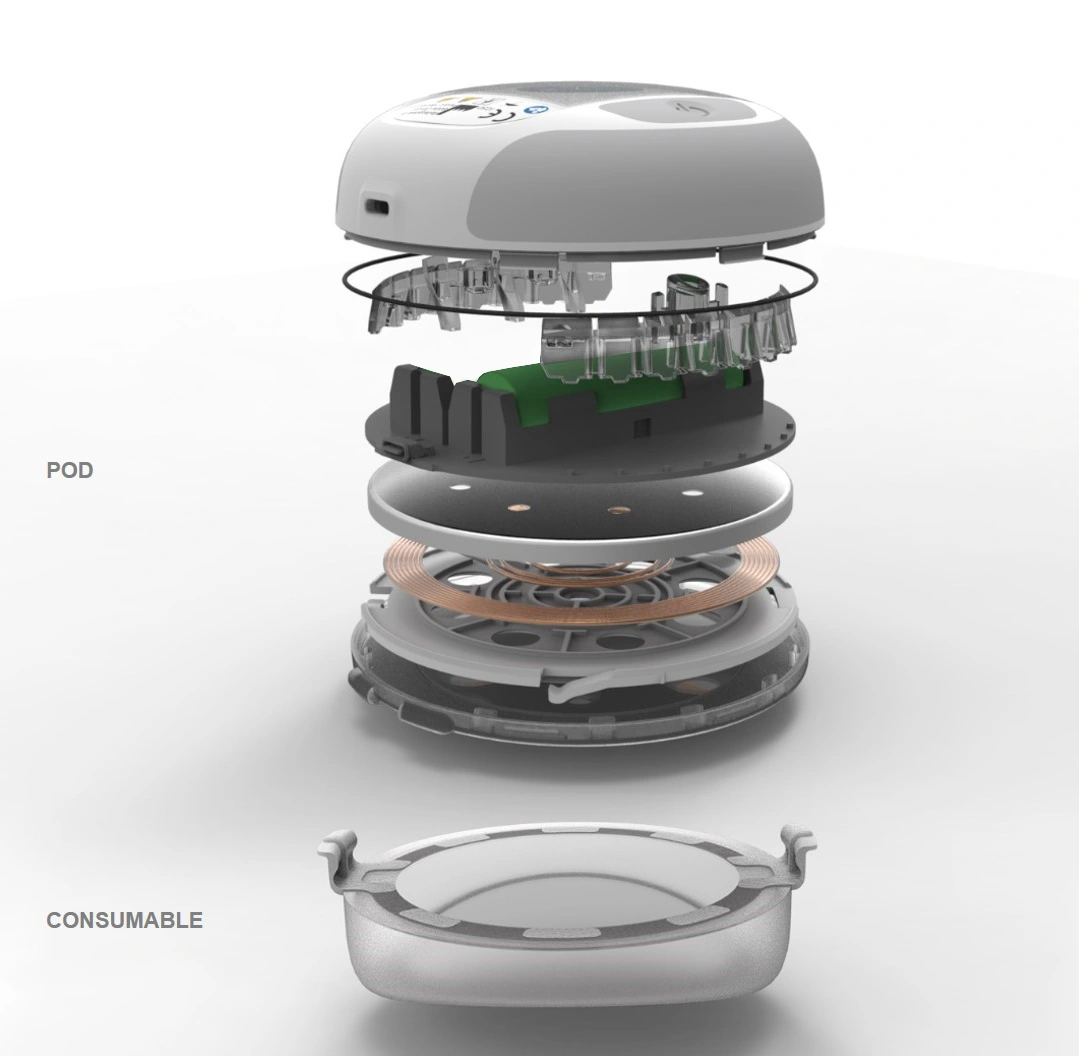

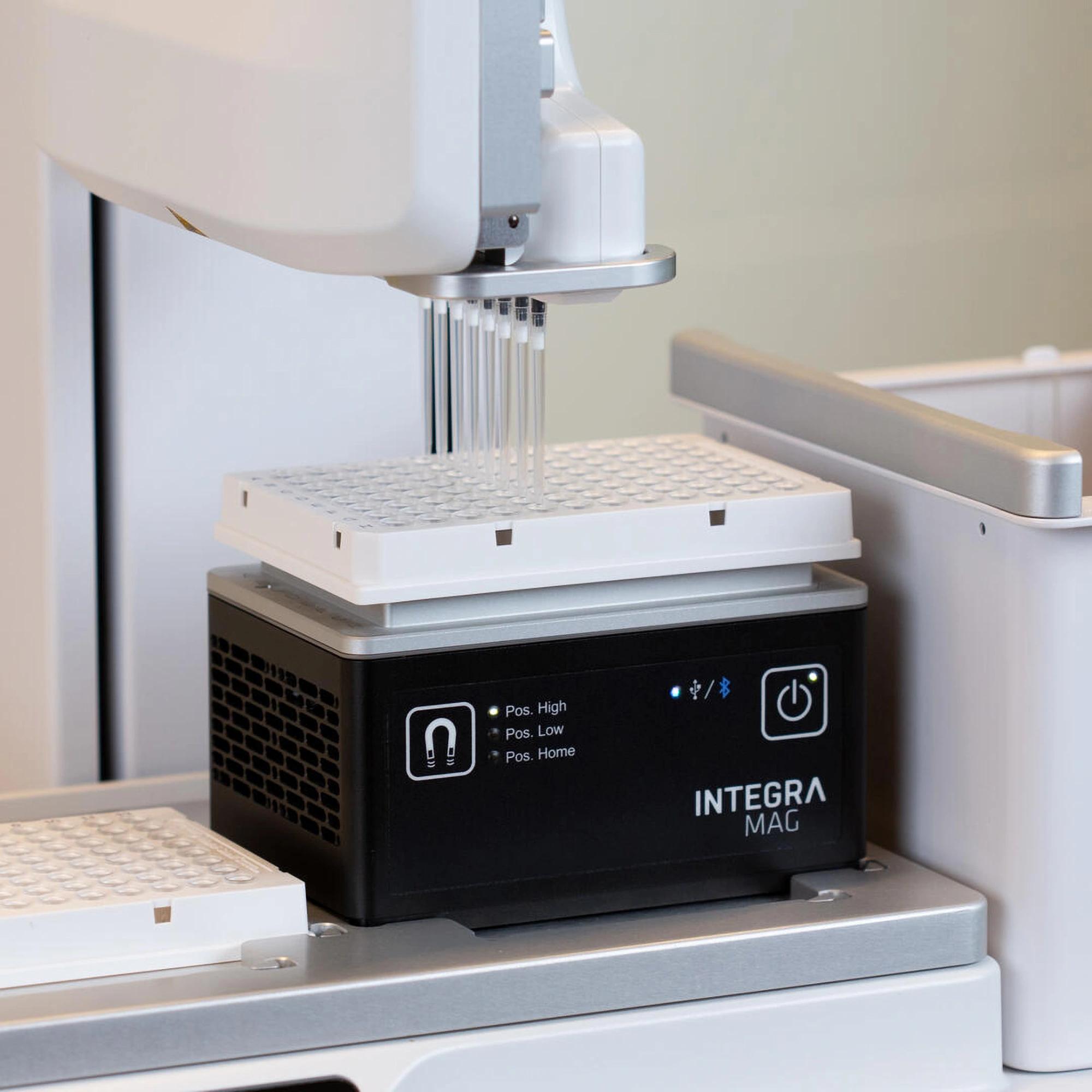

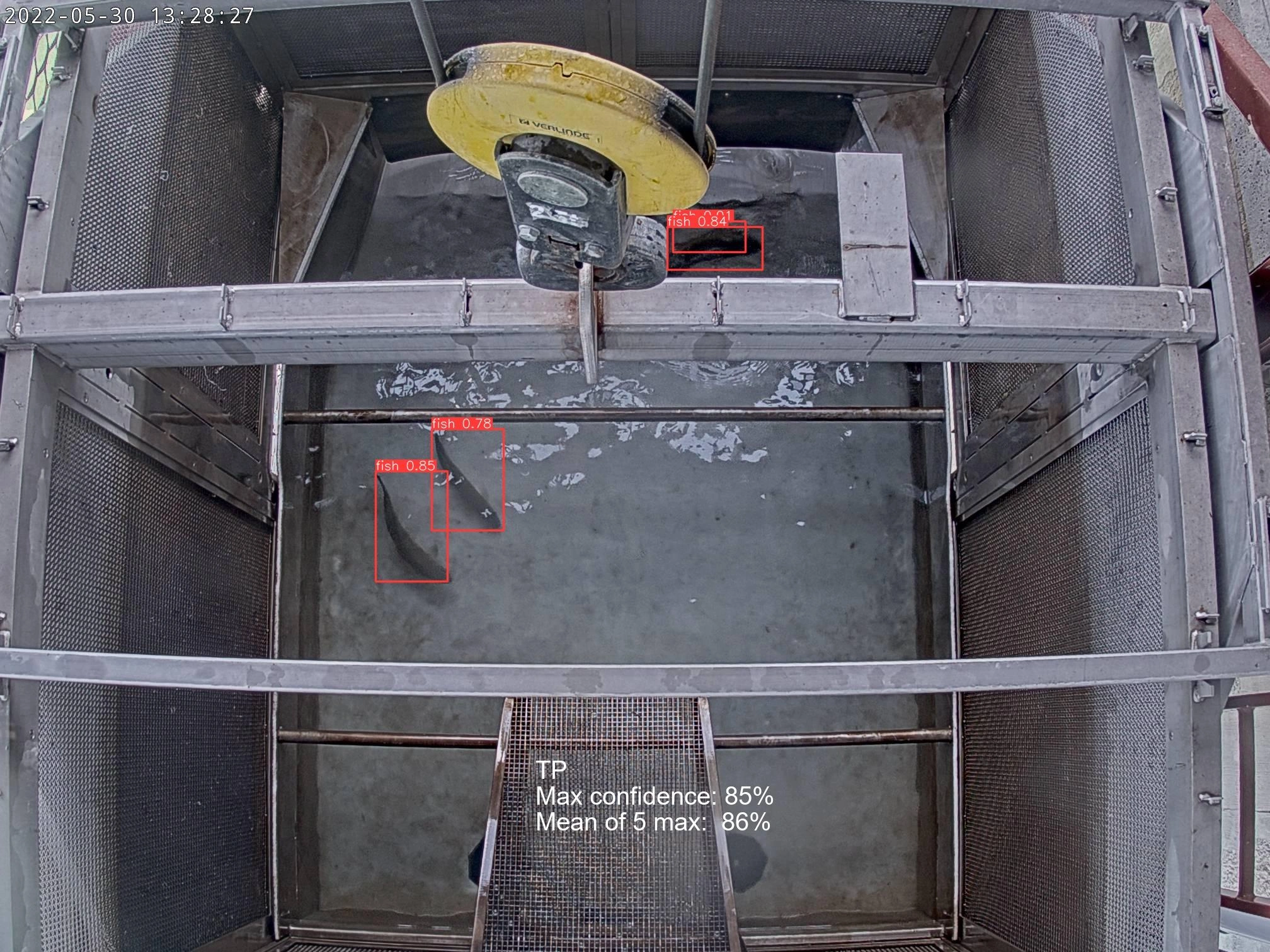

Gel card technology is used to determine blood type and has become a well-established and widespread standard method. Gel cards on laboratory machines are automatically processed in high throughput applications. Together with a medtech company, Helbling has developed a gel card spinner module deployed on one of the most up-to-date platforms for laboratory devices.

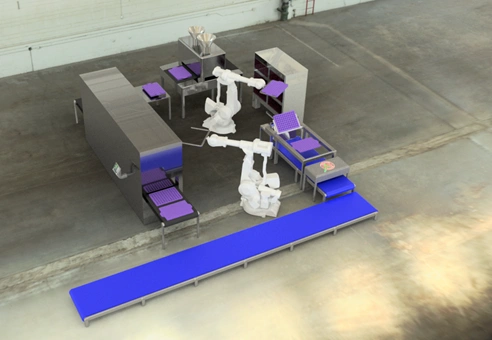

Driven by a customer project and a new application, a new gel card spinner module was to be designed and developed in minimal time. The fixed space ratios on the laboratory machine deck, the transfer positions to the gripper and the xyz robot as well as control via a defined electronics and software interface needed to be accounted for.

Since the company’s own development department was working to capacity on other projects, our customer took the decision to develop the product with an external partner that had the required know-how. Experience in agile system development, the design of rotating machines, electronics and software was particularly important. On the basis of these criteria, the customer chose Helbling and thus to continue the successful collaboration which had already begun many years before.

Driven by a customer project and a new application, a new gel card spinner module was to be designed and developed in minimal time. The fixed space ratios on the laboratory machine deck, the transfer positions to the gripper and the xyz robot as well as control via a defined electronics and software interface needed to be accounted for.

Since the company’s own development department was working to capacity on other projects, our customer took the decision to develop the product with an external partner that had the required know-how. Experience in agile system development, the design of rotating machines, electronics and software was particularly important. On the basis of these criteria, the customer chose Helbling and thus to continue the successful collaboration which had already begun many years before.

- Four spinners per module

- Independent centrifugation of four gel cards

- n modules stackable

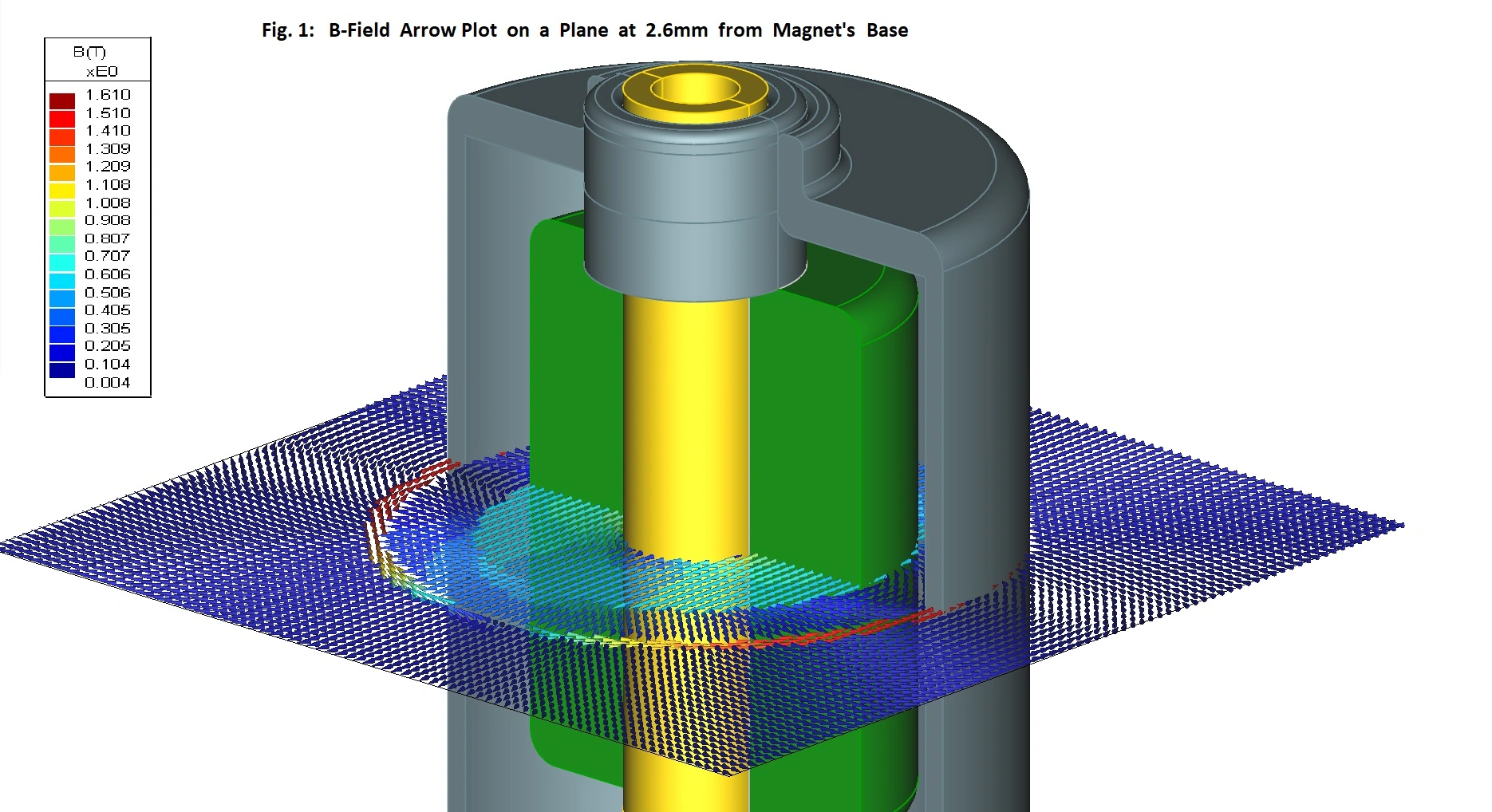

- 0 – 2,500 rpm

- Low noise, statically balanced

- Position-regulated EC drives

- Robotic loading/unloading positions

- Hermetically sealed through protective guards

- Free of contamination

- CAN bus interface

Services

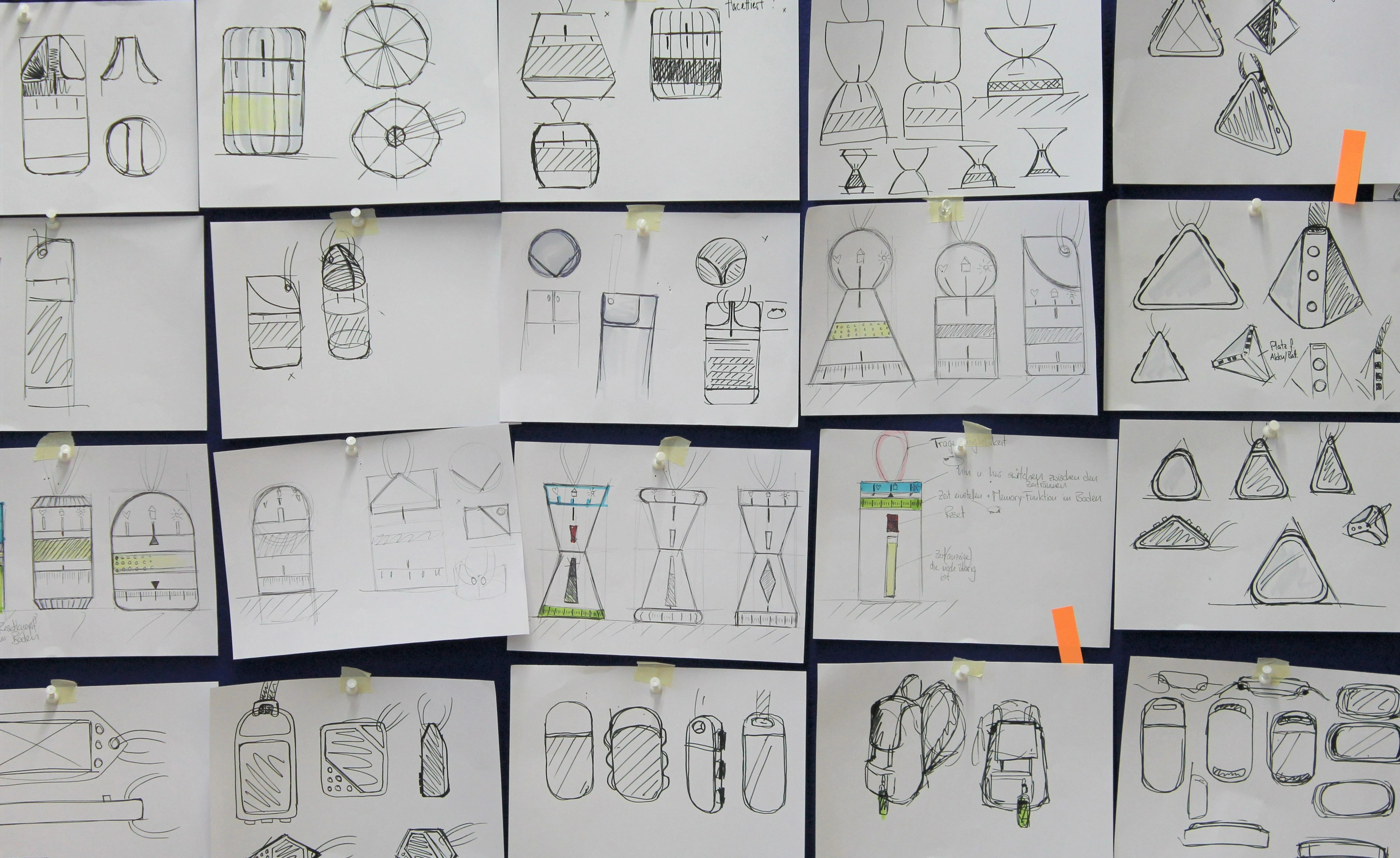

- Developing approaches for core functions after short concept phase

- Deploying a project team for accelerated development using an agile process in which all components are developed in parallel

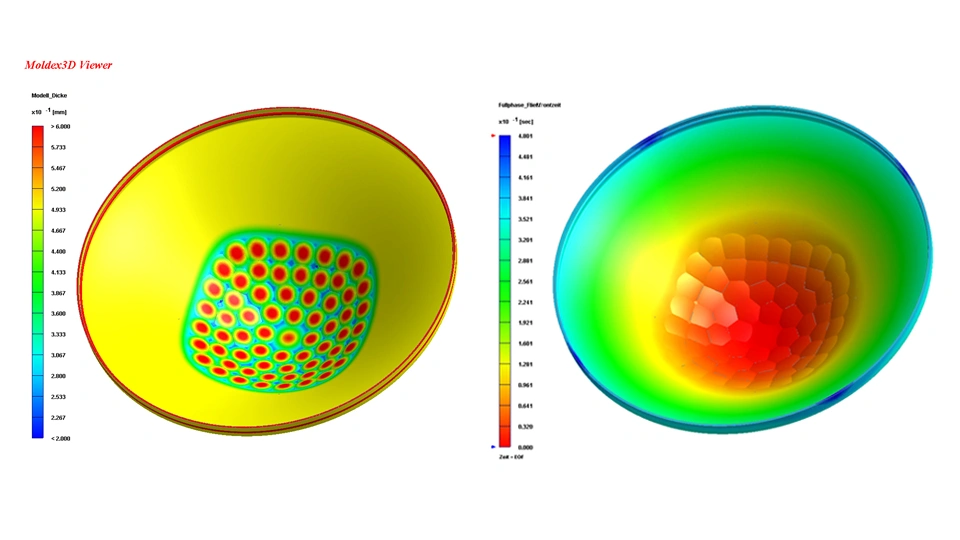

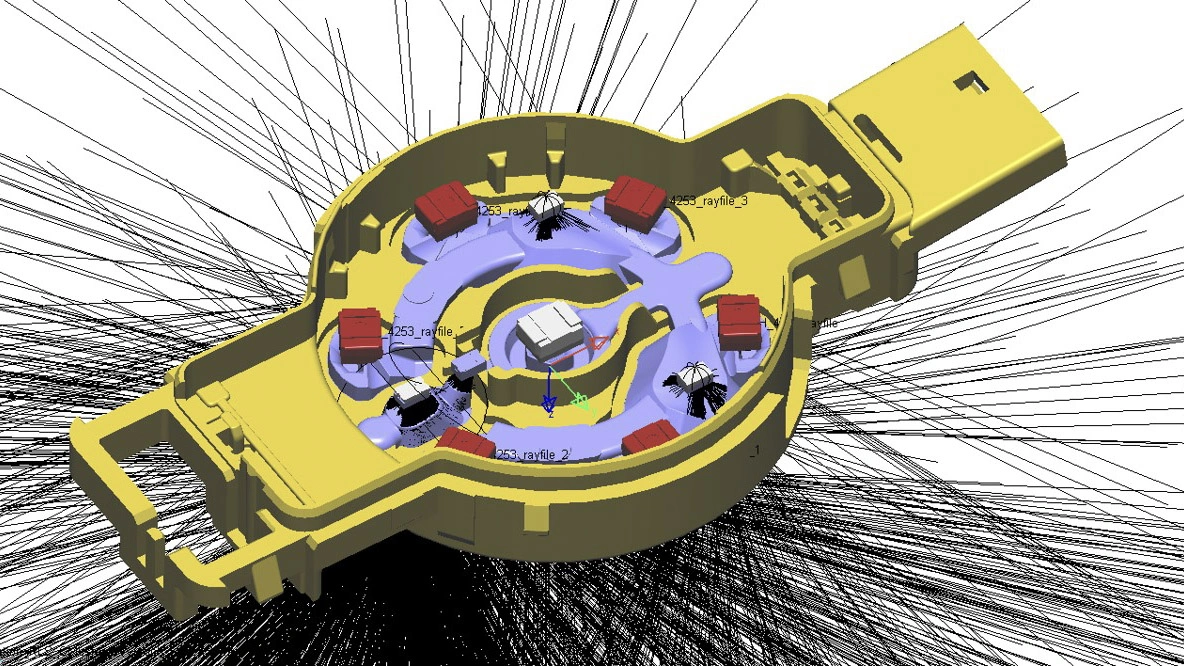

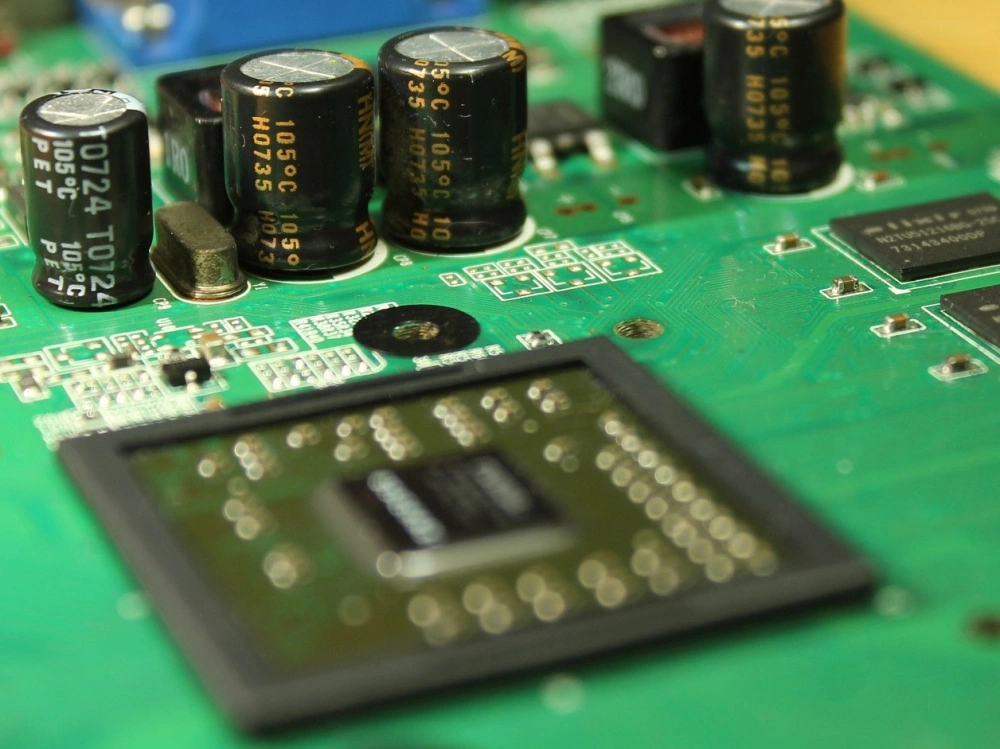

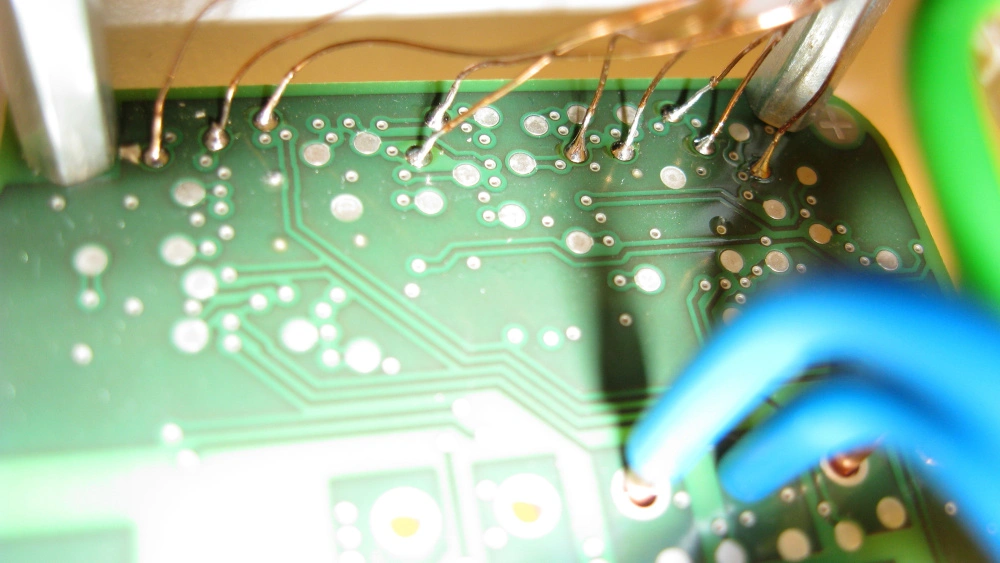

- Developing the mechanics with module chassis, gel card holder, hood with locking function, spinner drive, sensors, actuator, electronics board based on powerful controller with multiple uses already, cabling and connection technology

- Firmware/software with the development of HAL, the module functions and the command interface to the laboratory machine control

- Throughout development standards for electrical safety, personal protection and EMV were taken into account consistently

- Production of several prototypes

- Design and verification tests

- Production of manufacturing documentation for final design and transfer of design history file to the customer

Result / Success

In less than six months, Helbling had developed the product and transferred it to the client in a fully verified pre-production state.

The module is available for customer-specific applications and processes and is used together with a very successful device platform.

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

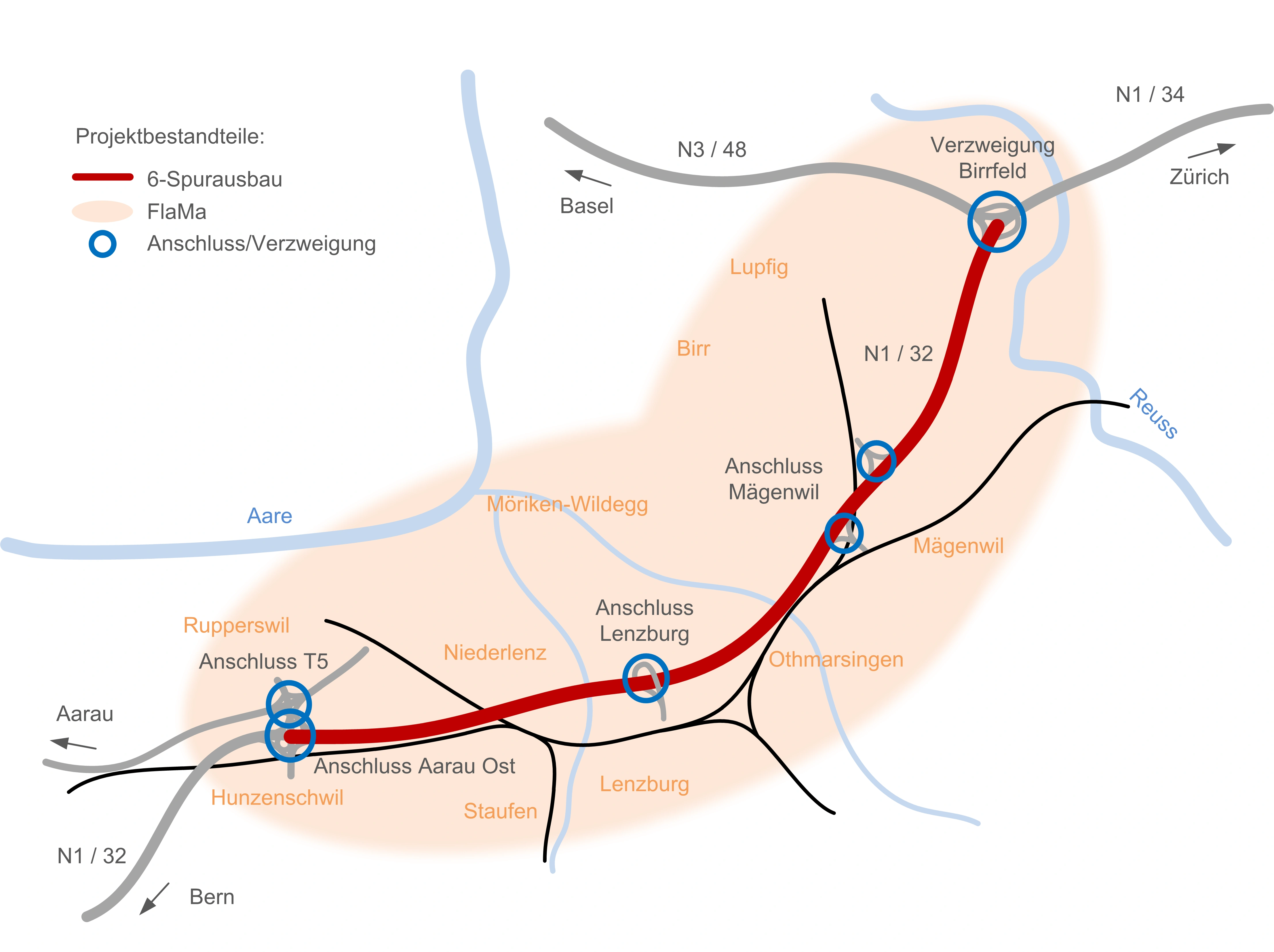

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: