REFERENCE PROJECT

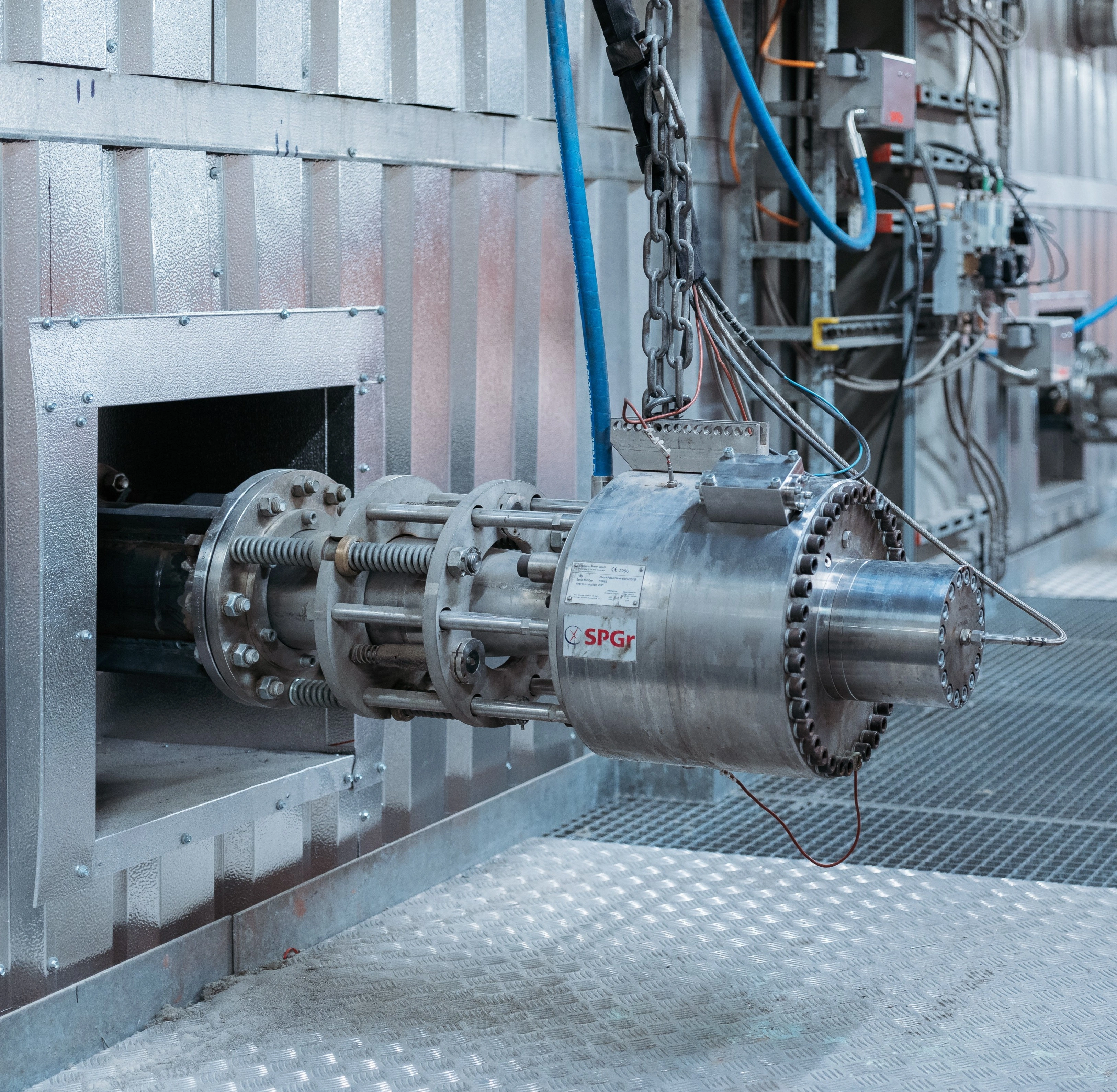

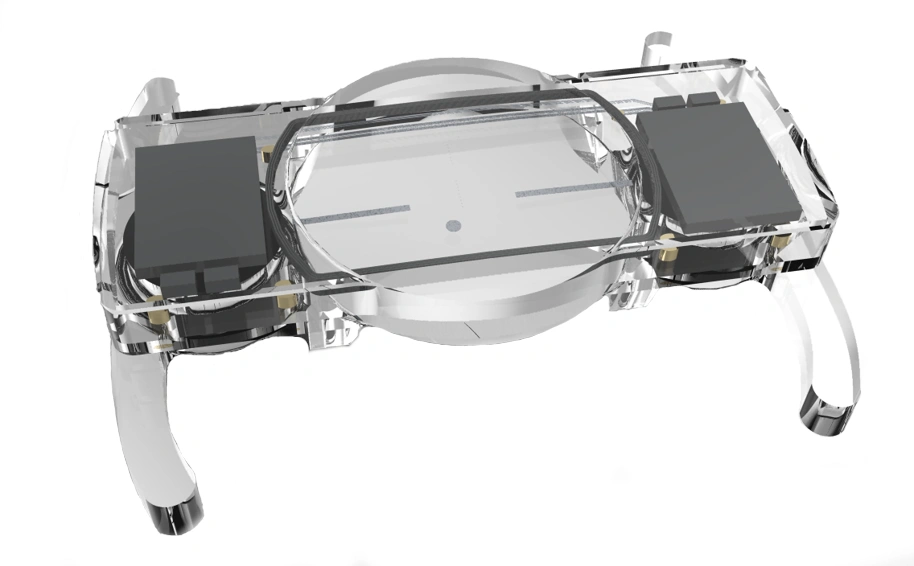

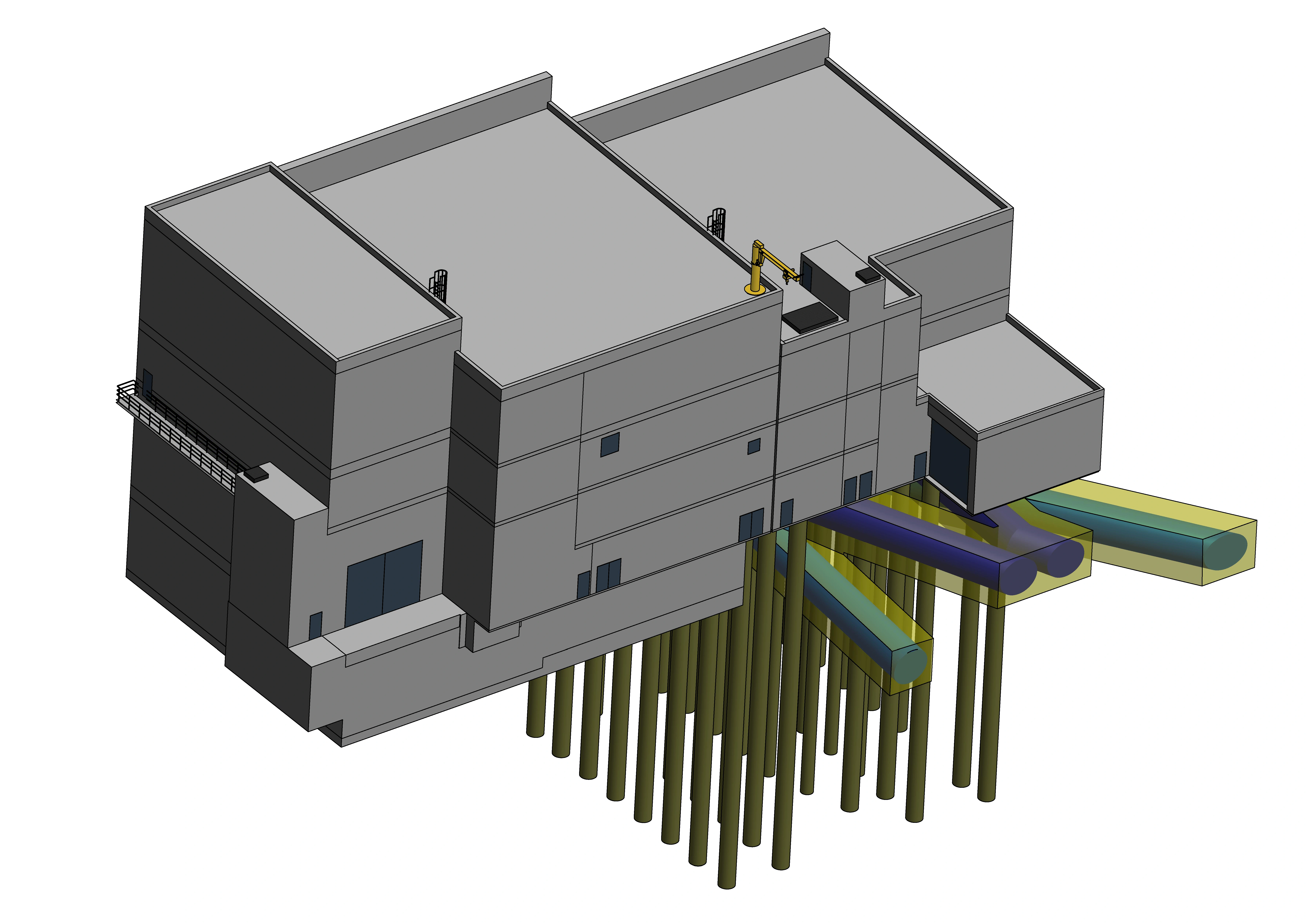

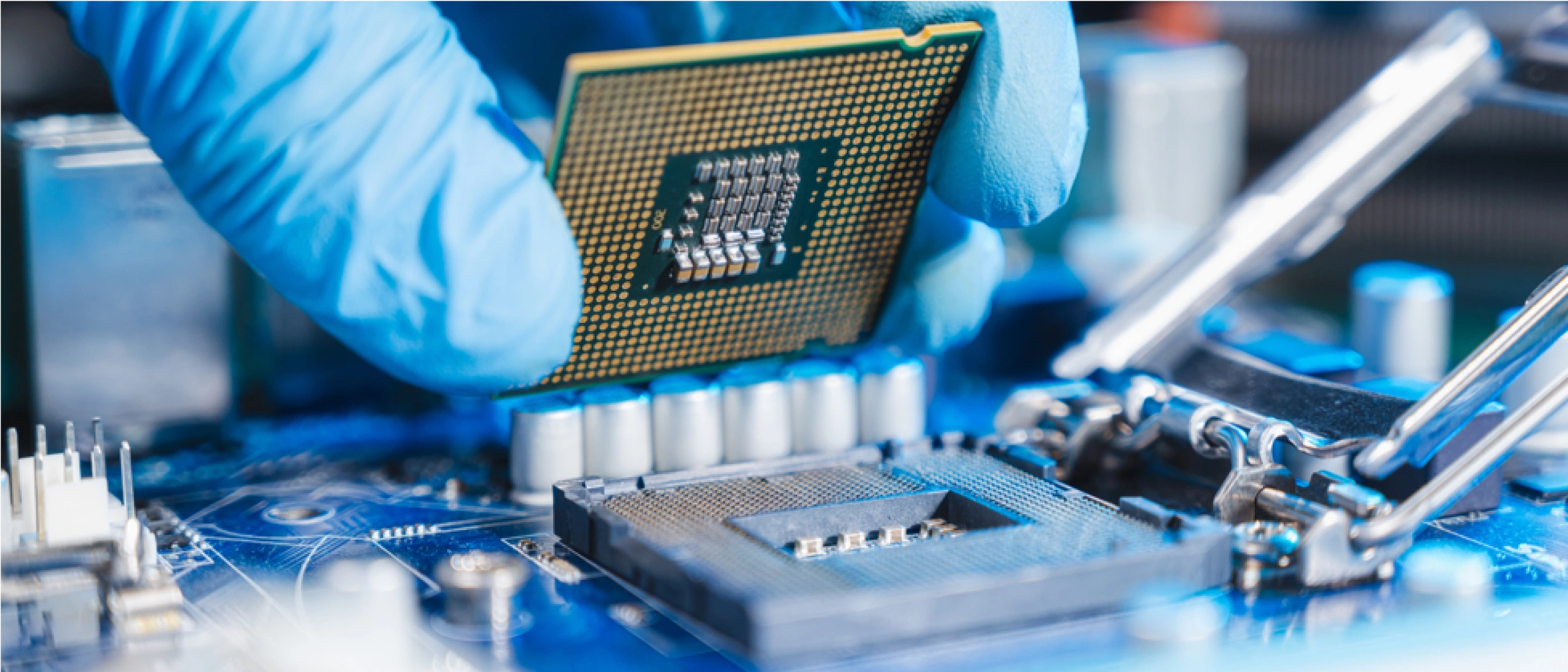

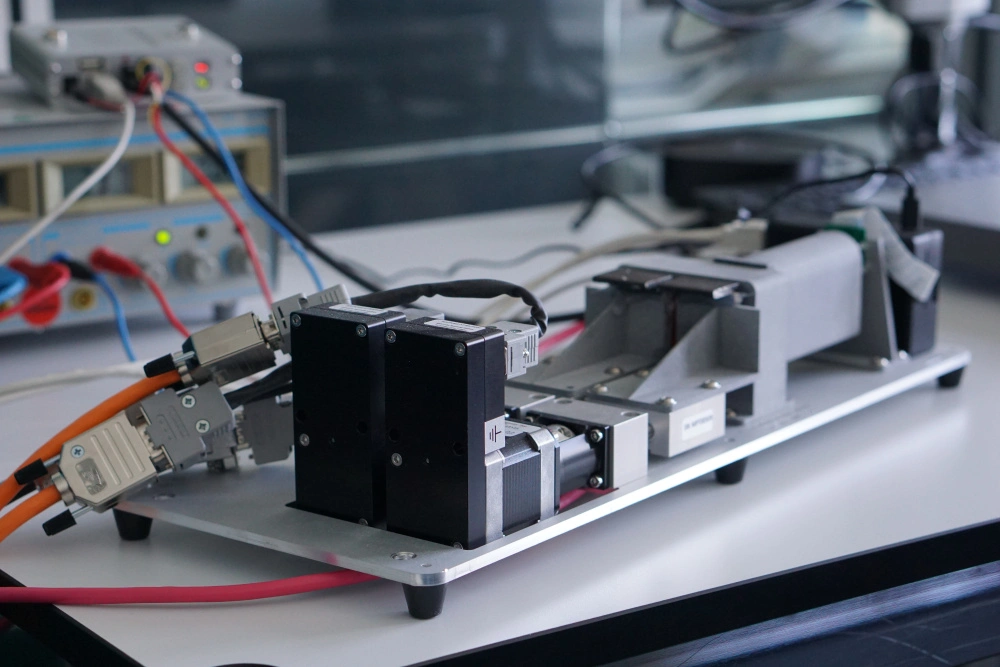

Turnkey test systems for 2.5 MVA inverters and power modules

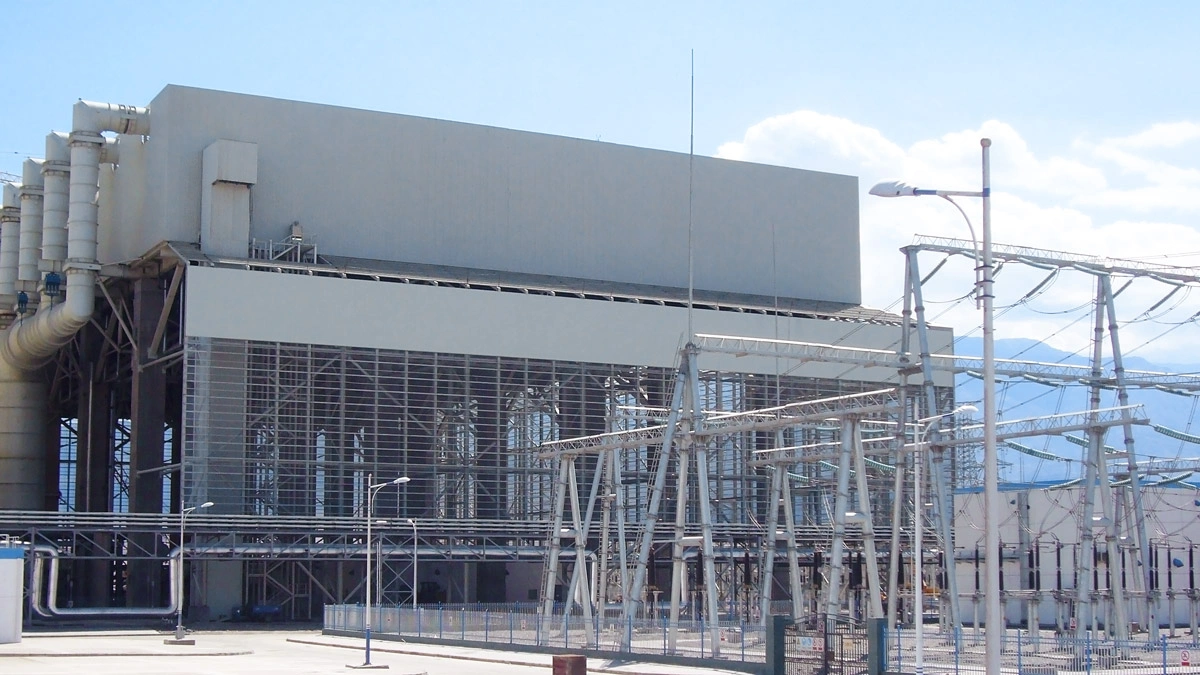

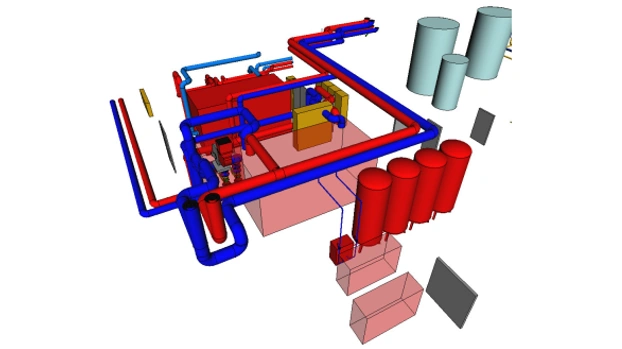

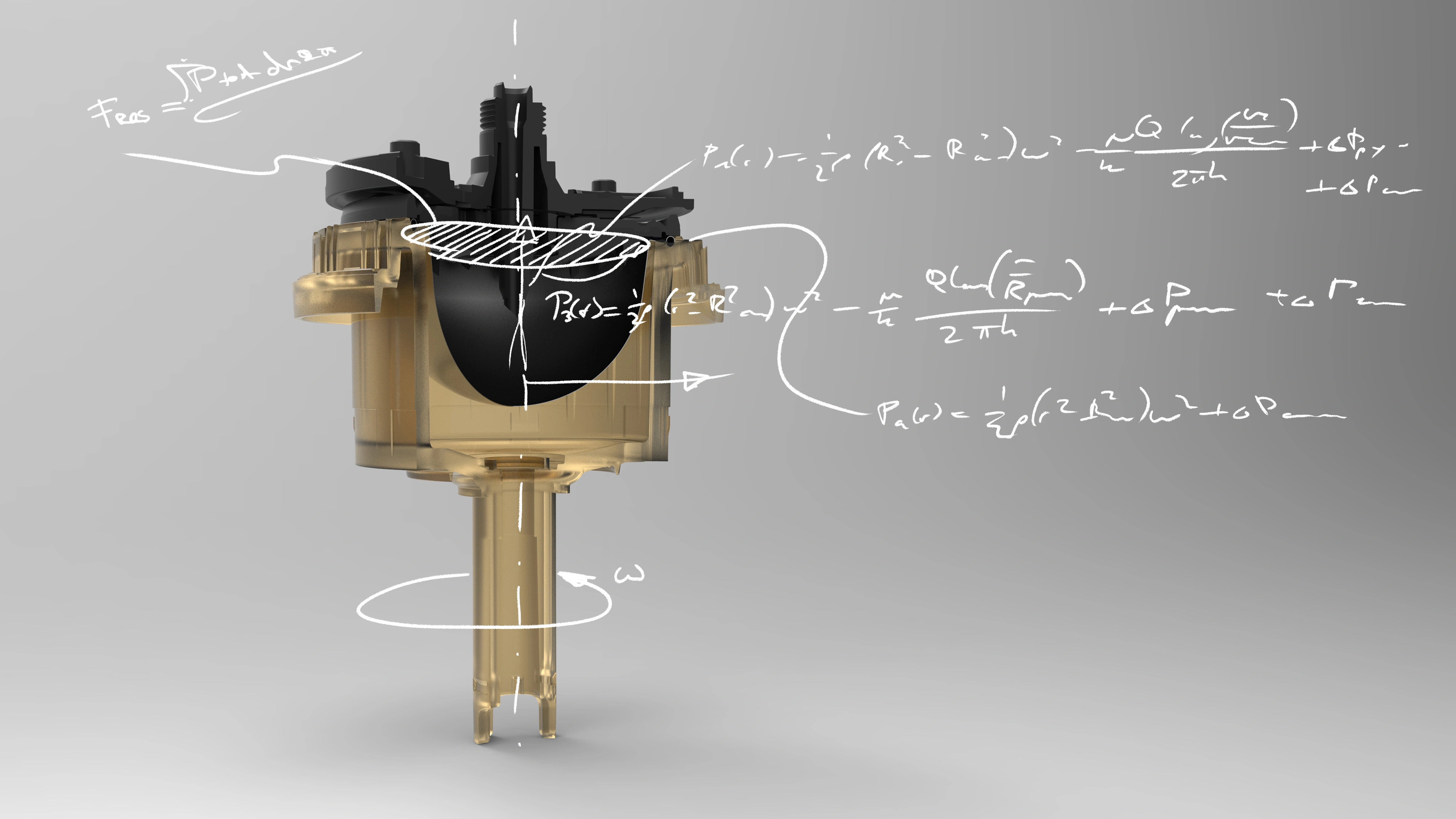

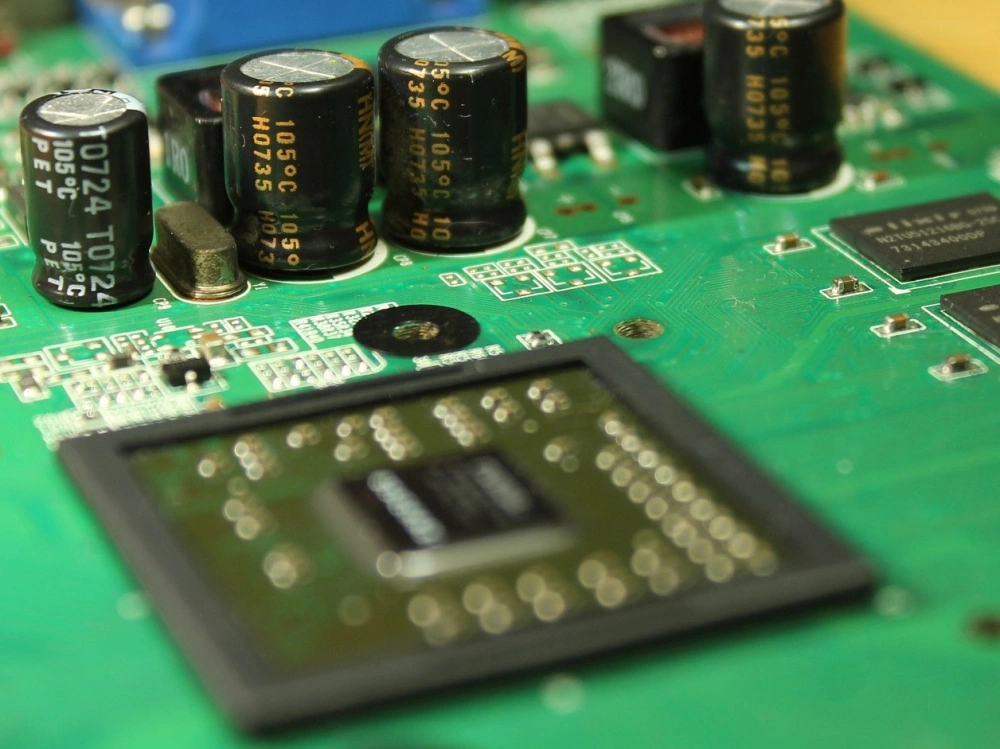

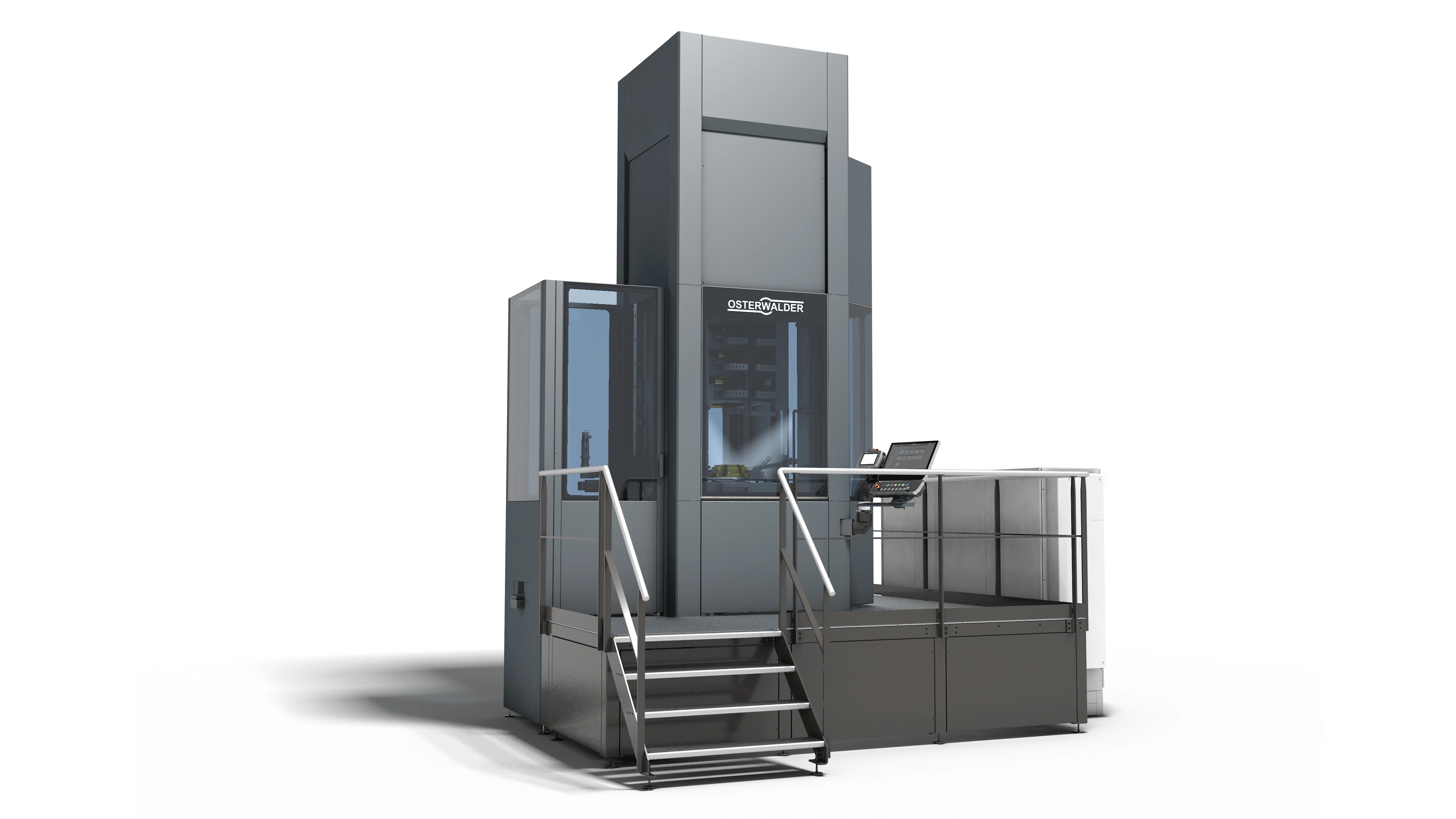

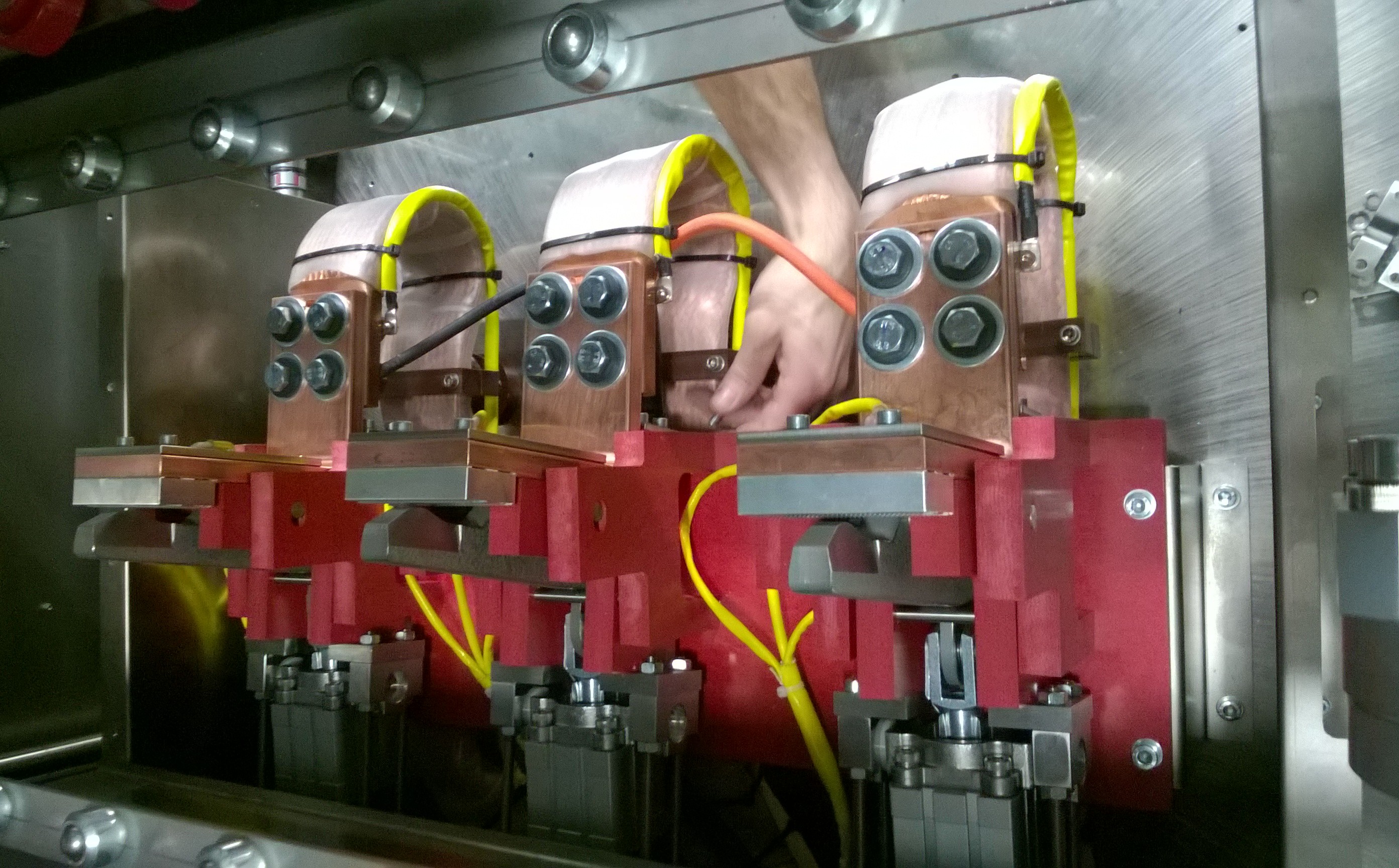

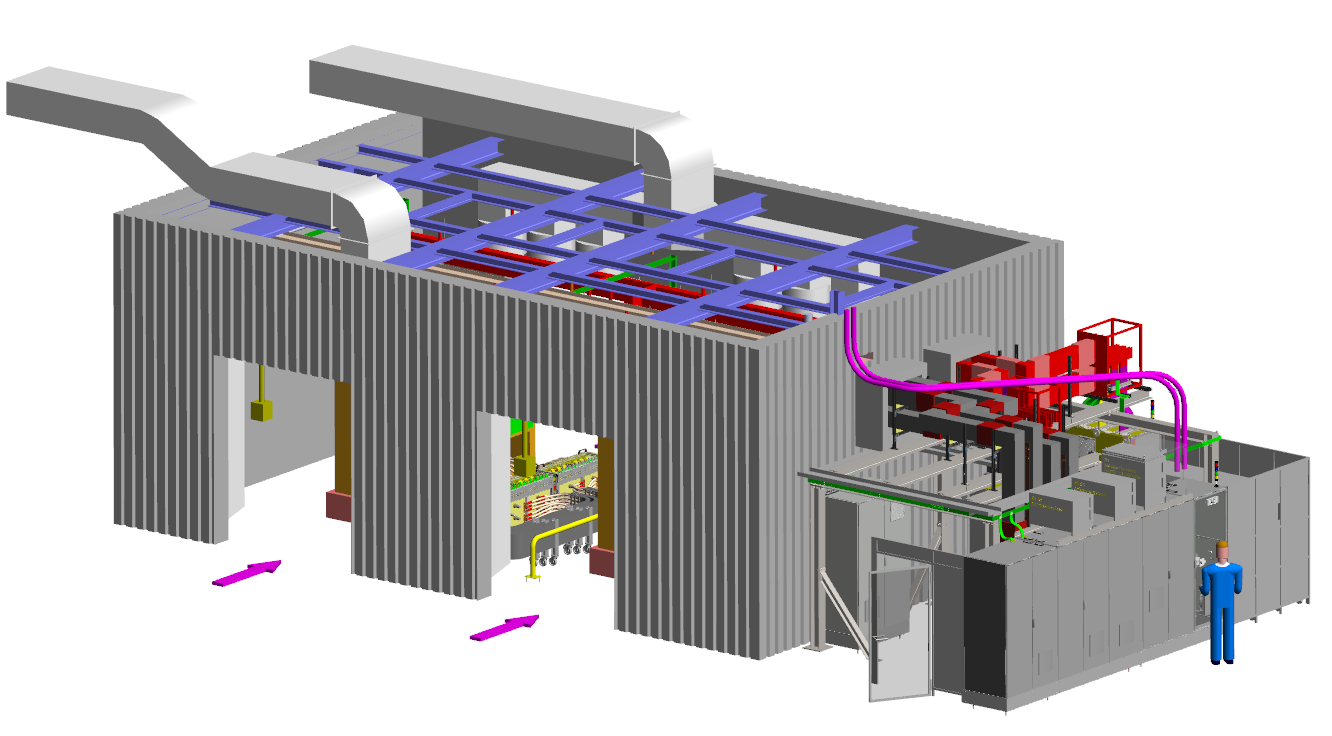

Our client, a leading manufactor of quality products in the energy sector, was facing the market launch of a new generation of inverters in the 2.5 MVA class (equivalent od the output of a solar area of approx. 4 football fields).

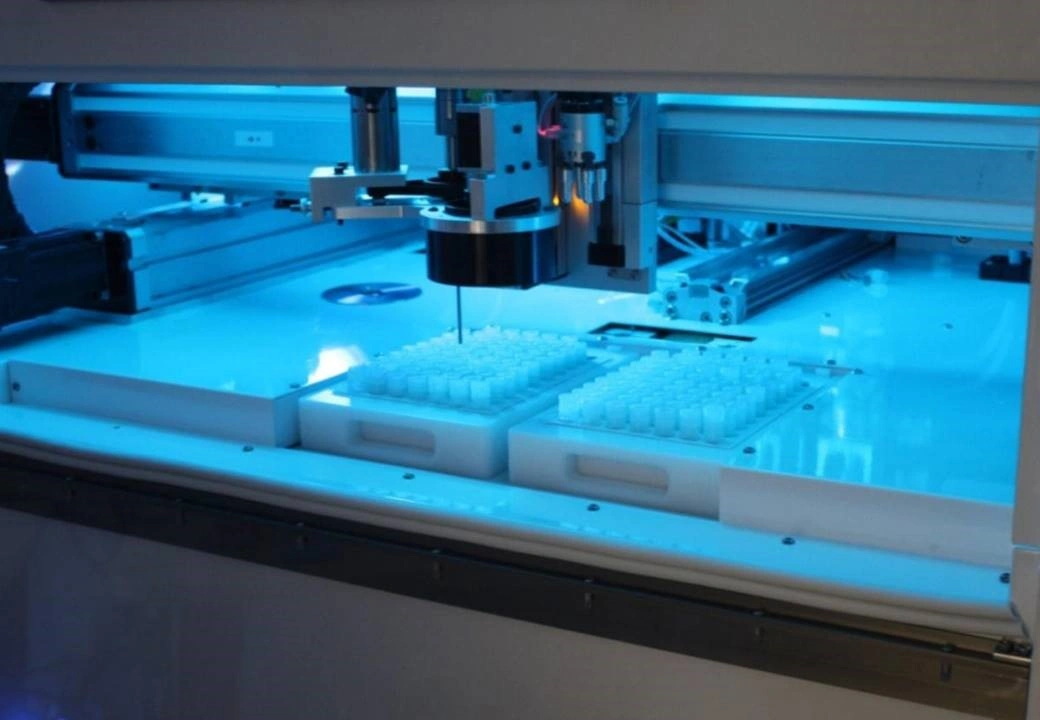

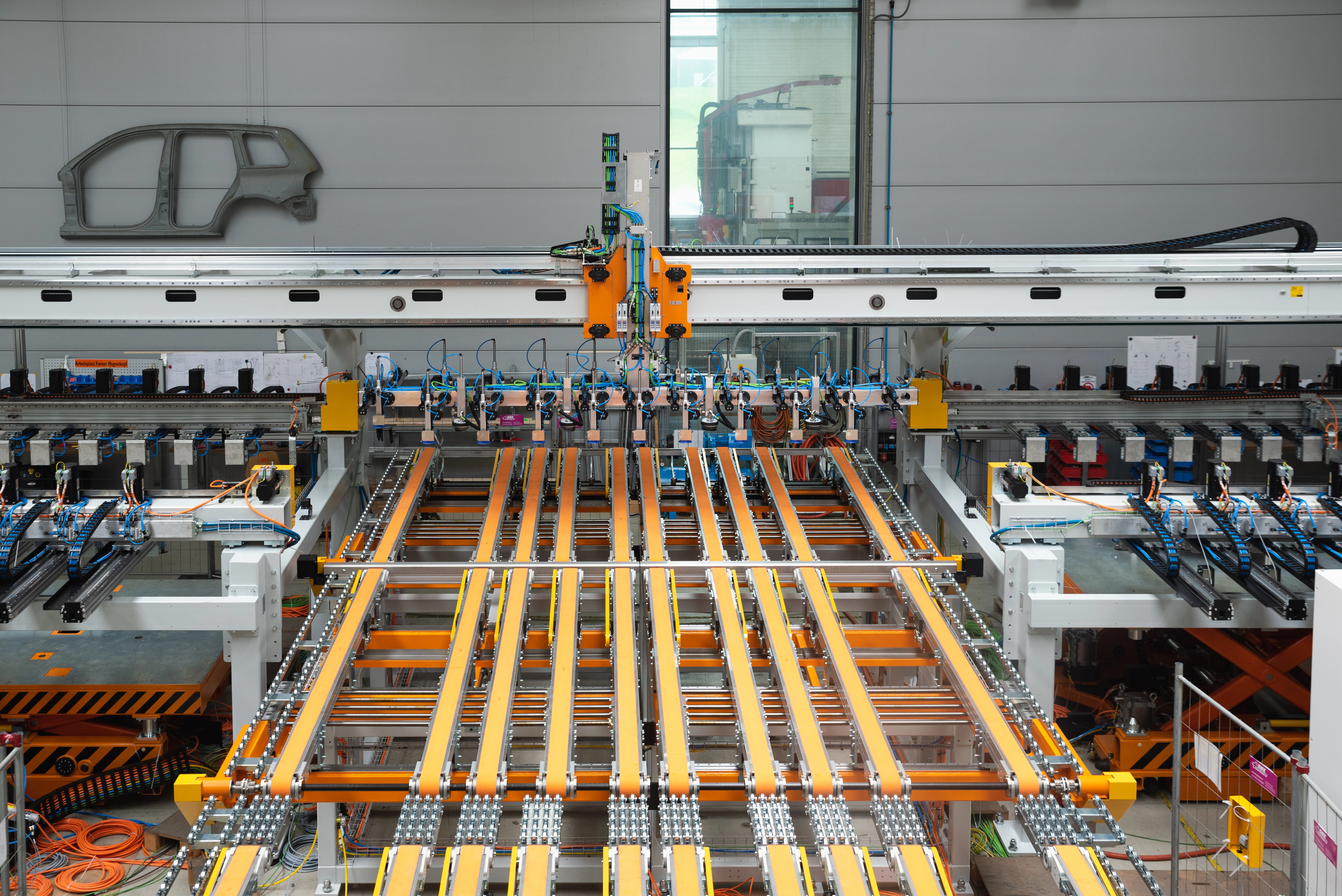

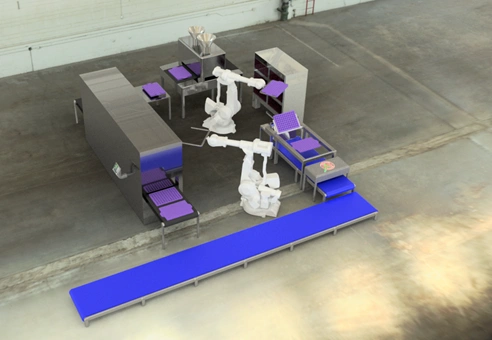

These inverters and their power modules must be tested in the production line.

His challenges were:

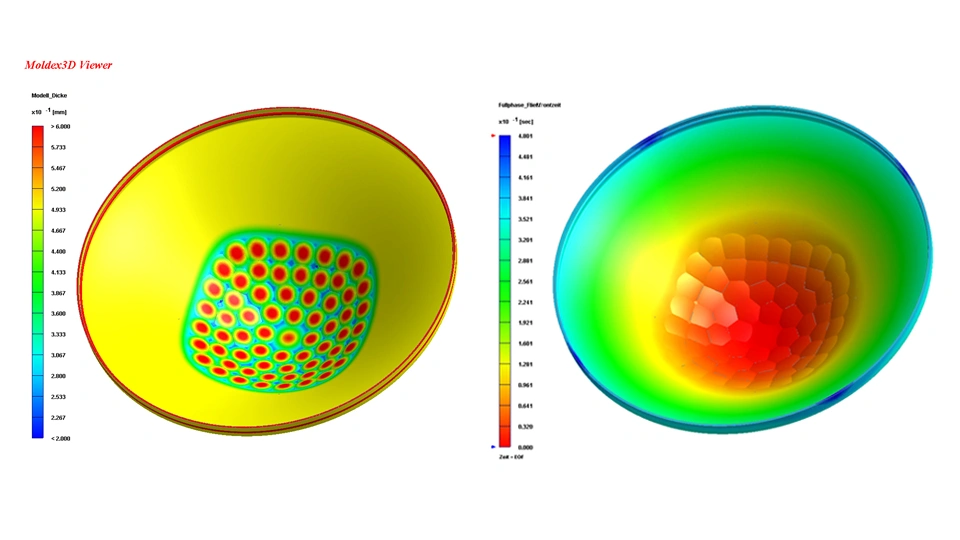

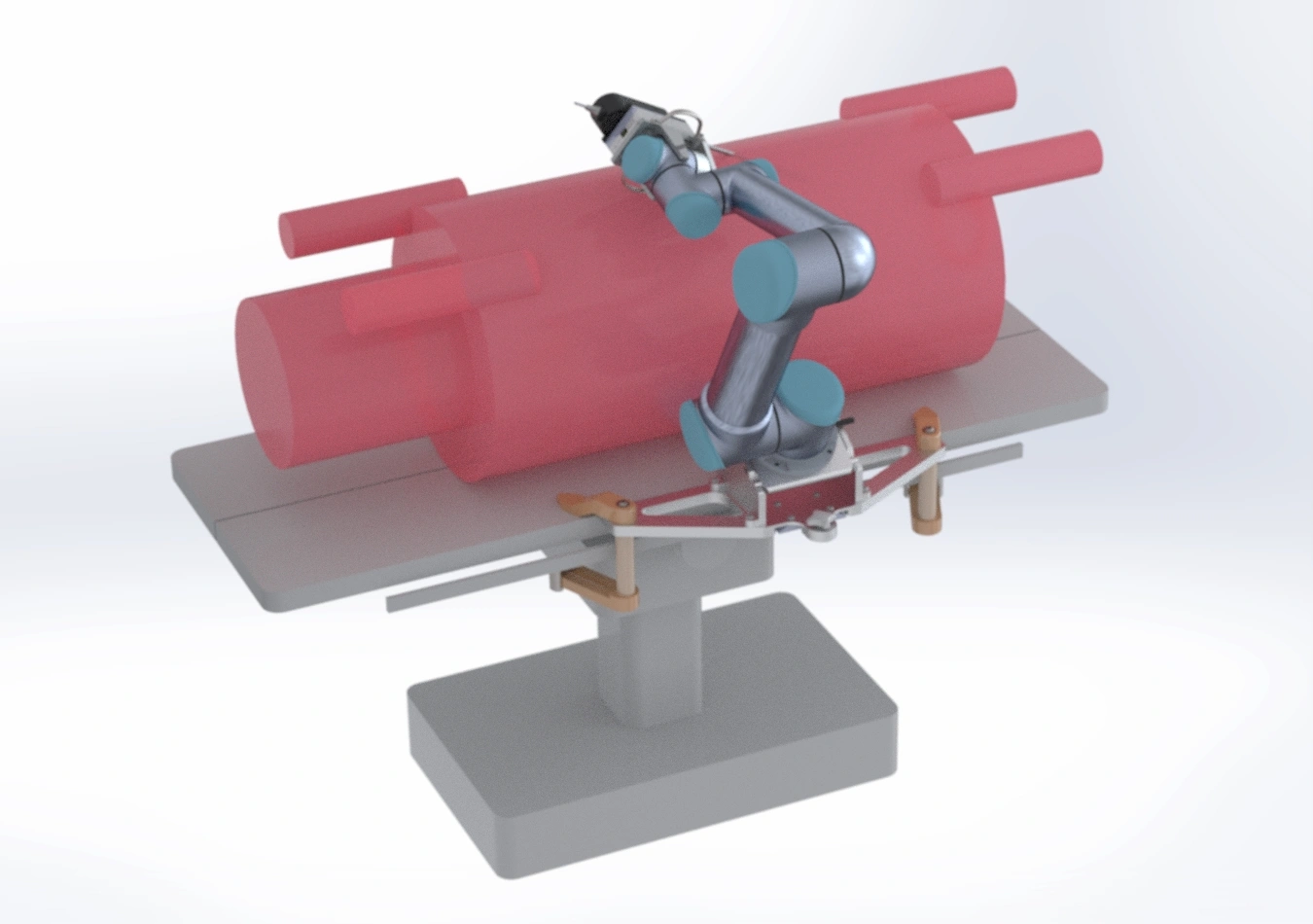

- Complexity: Test systems were required that could test both the individual power modules and the complete inverters under load.

- Time pressure: The deadline for the “Start of Production” (SOP) was given. Time-to-market was the critical success factor.

- Integration: The system had to integrate seamlessly into the client’s existing process landscapes and IT structures.

The complexity of the project exceeded the resources of a system supplier. The client was looking for a partner for general planning and implementation, right up to final acceptance.

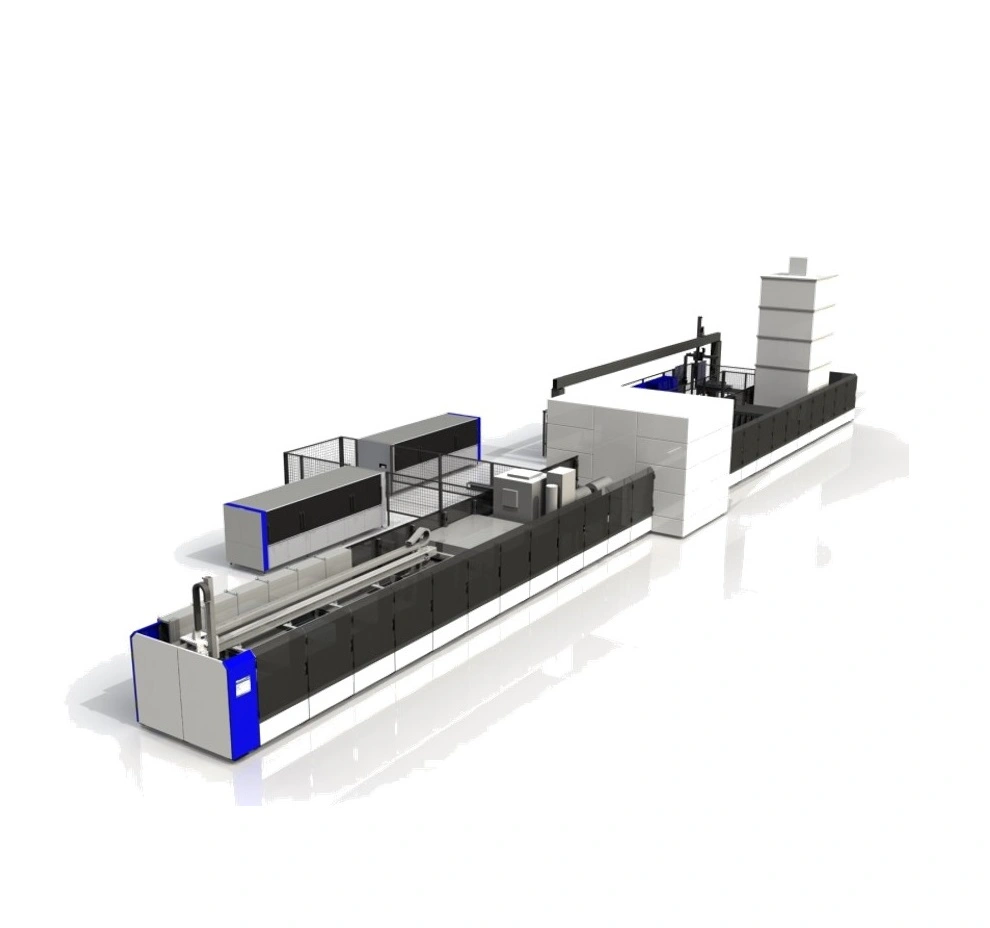

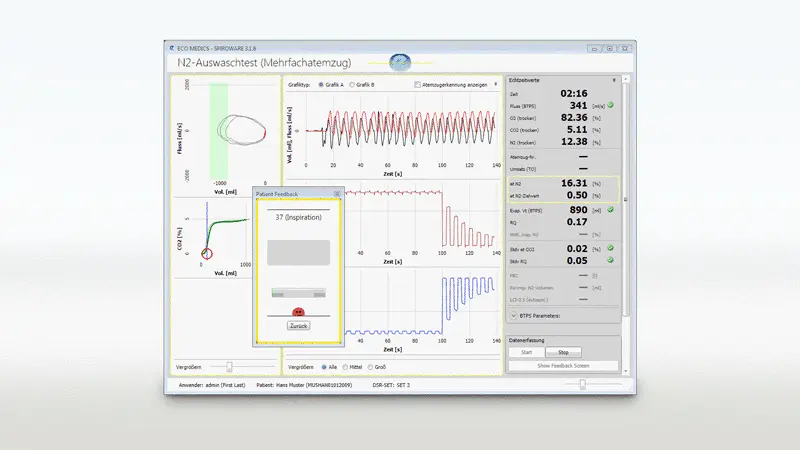

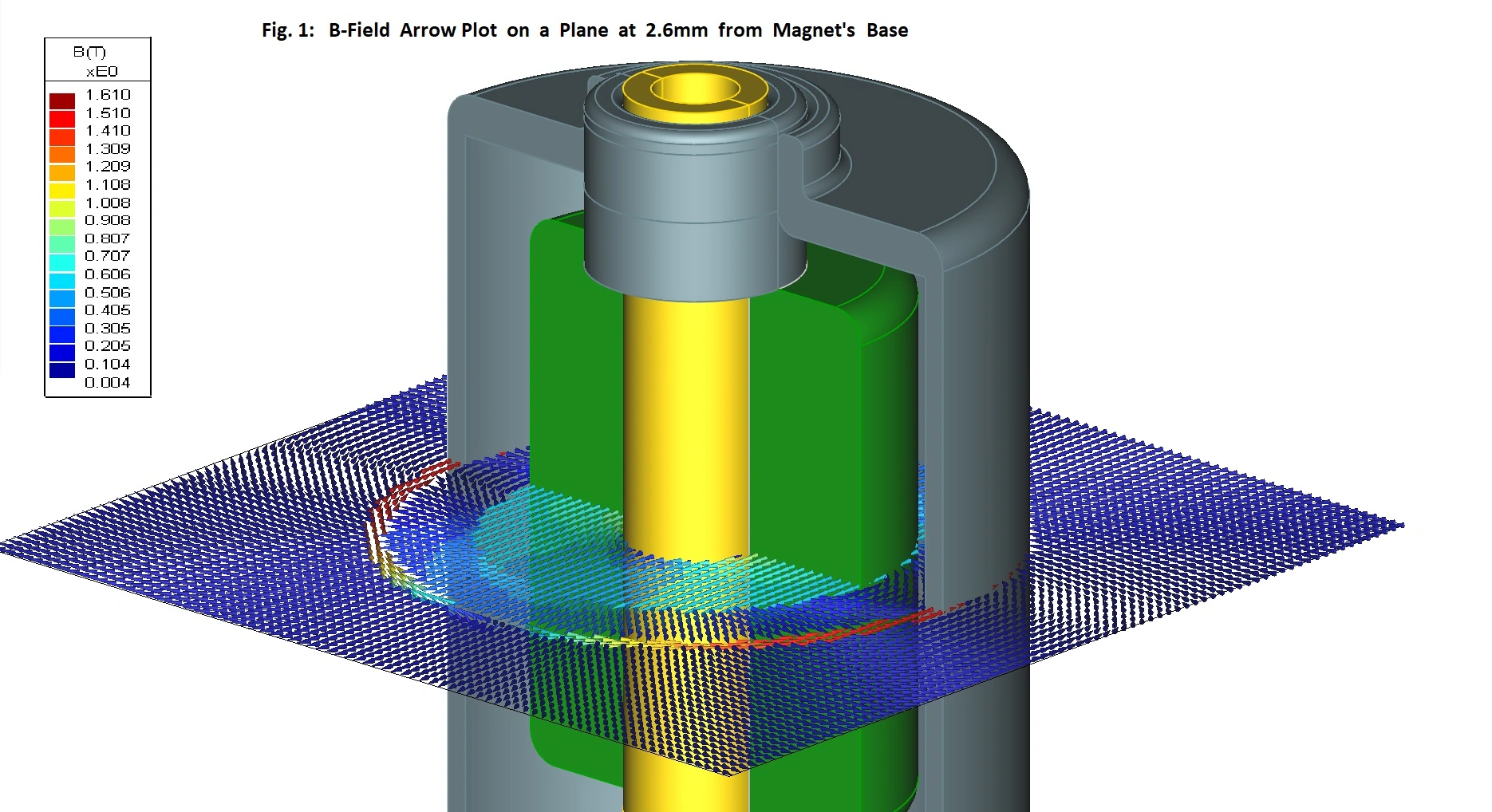

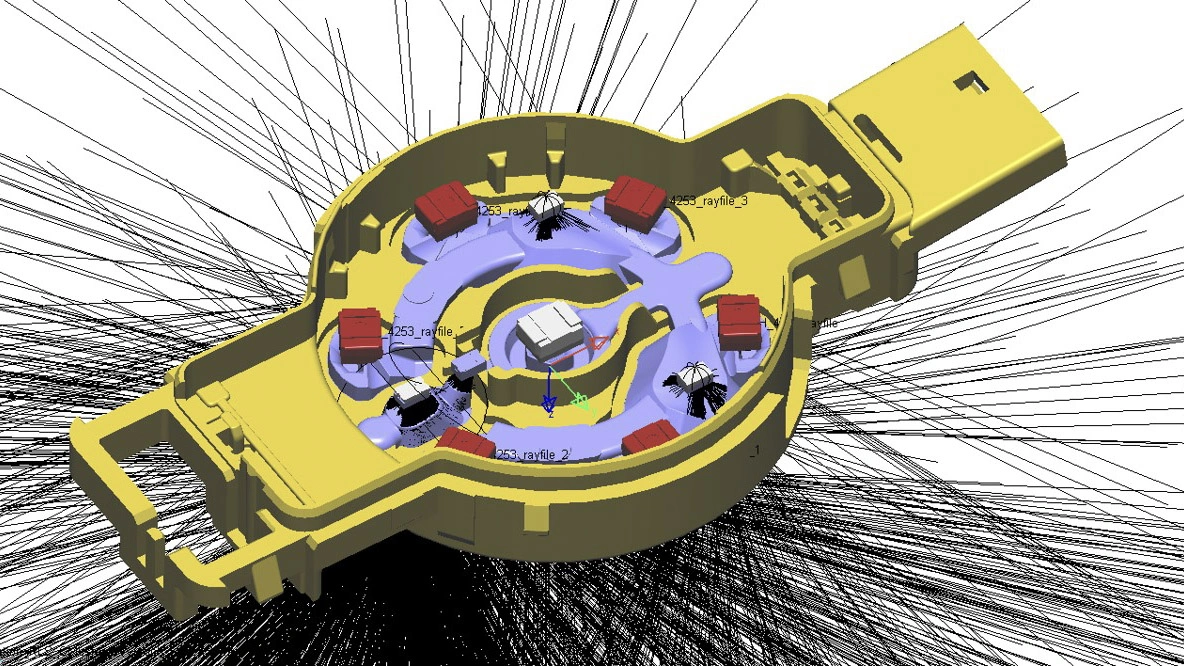

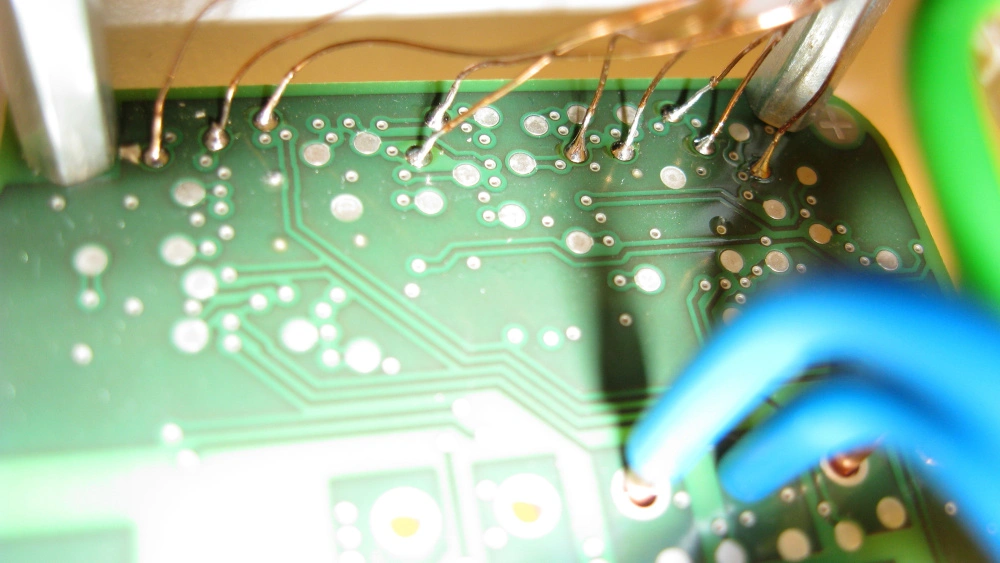

We acted as a general planner for the overall project and were responsible for each step from the first evaluation to the key handover as the “Single Point of Contact” for our client. Through professional supplier management & construction support, we took over the evaluation of technologies, selection and control of subcontractors as well as monitoring of on-site installation. The core of test systems was the test specification and the flexible test procedures. No less important were Safety & Compliance, which included carrying out the risk assessment for personal safety and implementing the safety measures – essential in the high-voltage & high-current area.

Services

Industries

Key Figures

- Energy / Power Electronics

- Project duration approx. 2 years

- Helbling team size 5 – 25 engineers (peak)

- Disciplines Mechanical Engineering, Electromechanics, Electronics, Software, Project Management

- NI PXI, Beckhoff PLC & SiSPS

- LabVIEW, TestStand, TwinCAT, MySQL, EPLAN, SolidWorks, MATLAB

Our Contribution

- From test specification through engineering and construction up to commisioning

- Professional procurement support, supplier management & construction support

- On-site commissioning (FAT at suppliers, SAT at the client)

- Training, handovers and knowledge transfer to the client

- Systems engineering

- Test specification

- Safety & Compliance

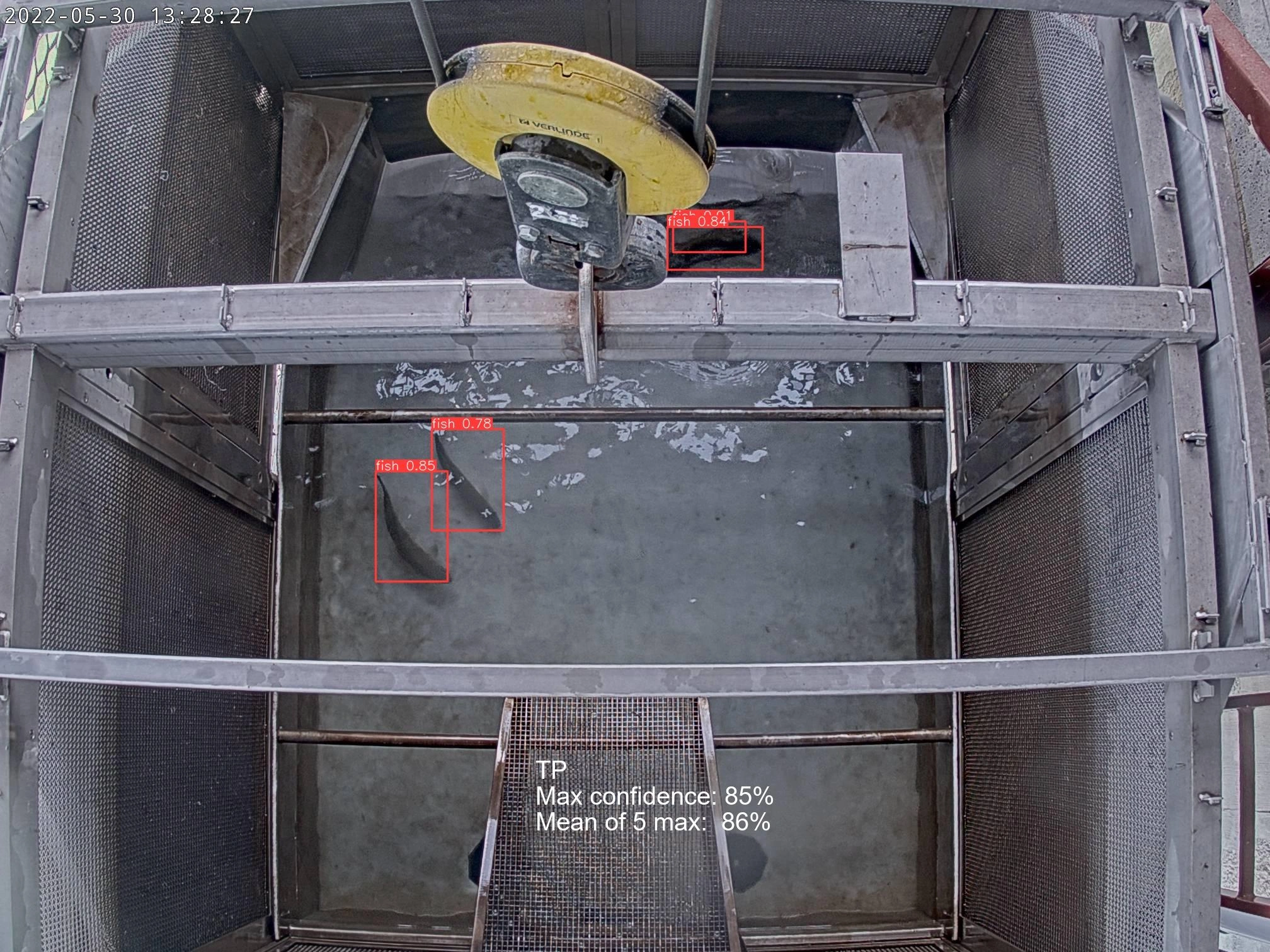

- Flexible test sequence control and reliable process control

- Software for complete traceability as well as maintenance and spare part management

Outcome

On-time handover of two fully automated, process-safe test systems that ensured the high quality standards from SOP on.

Contact

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

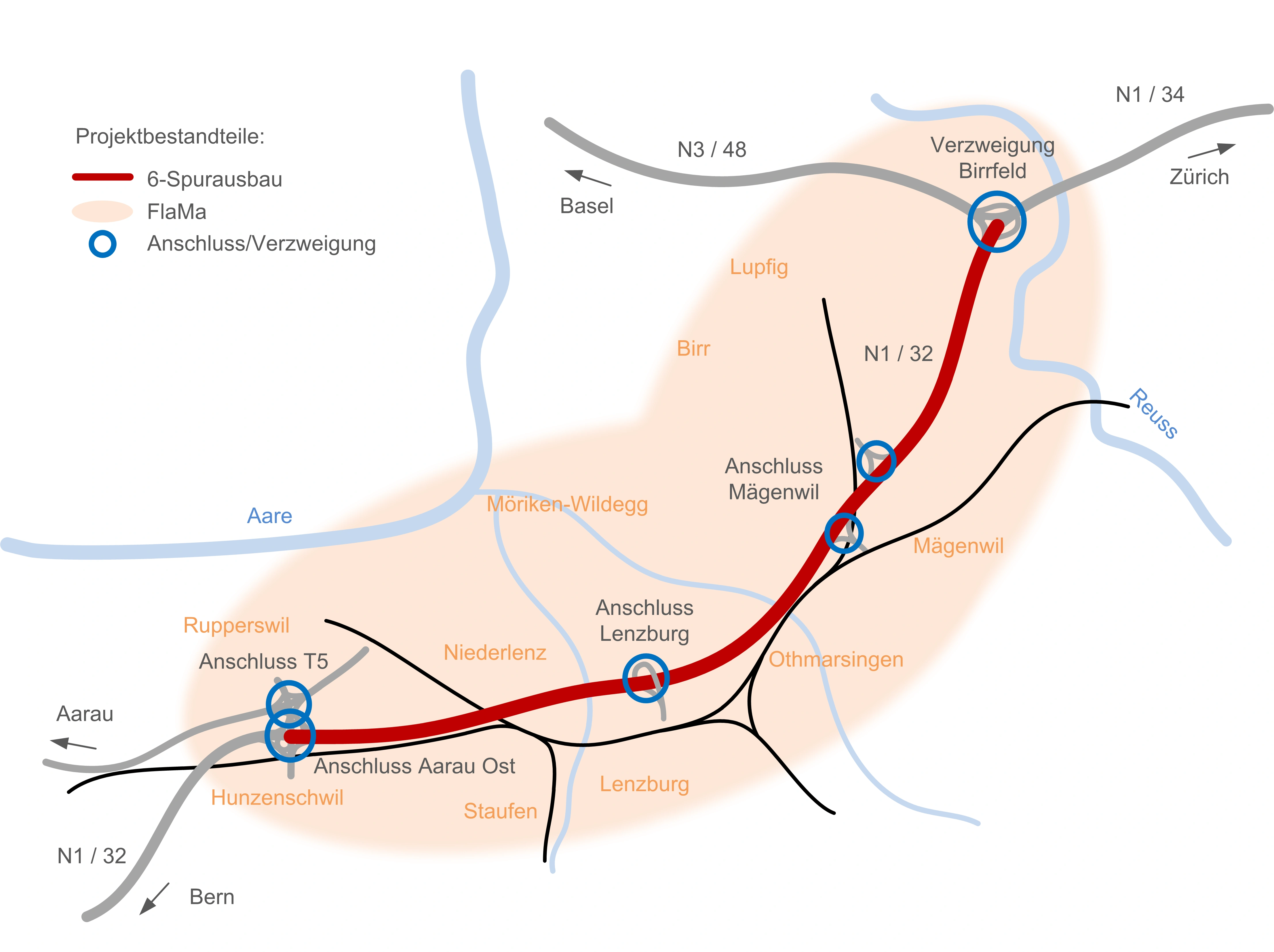

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: