REFERENCE PROJECT

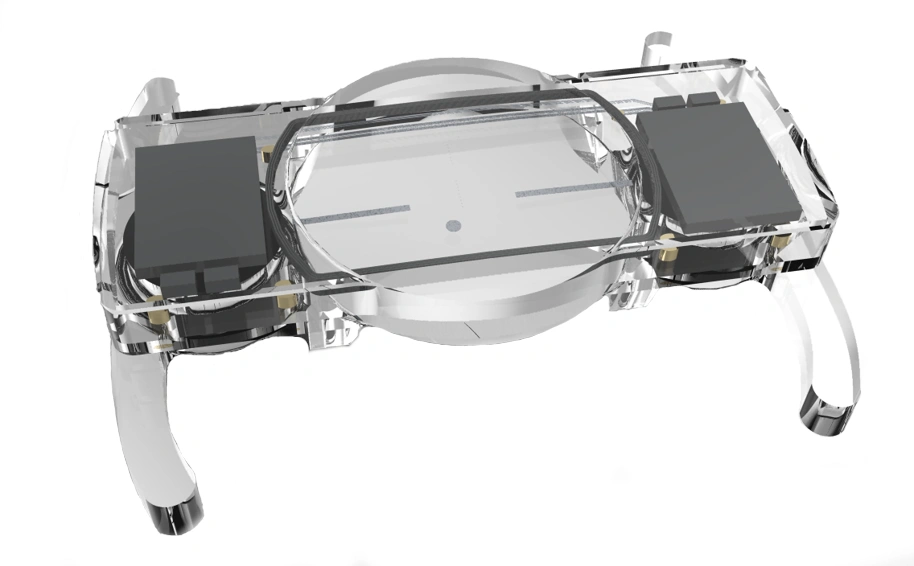

Expansion of global production capacities for auto-injectors

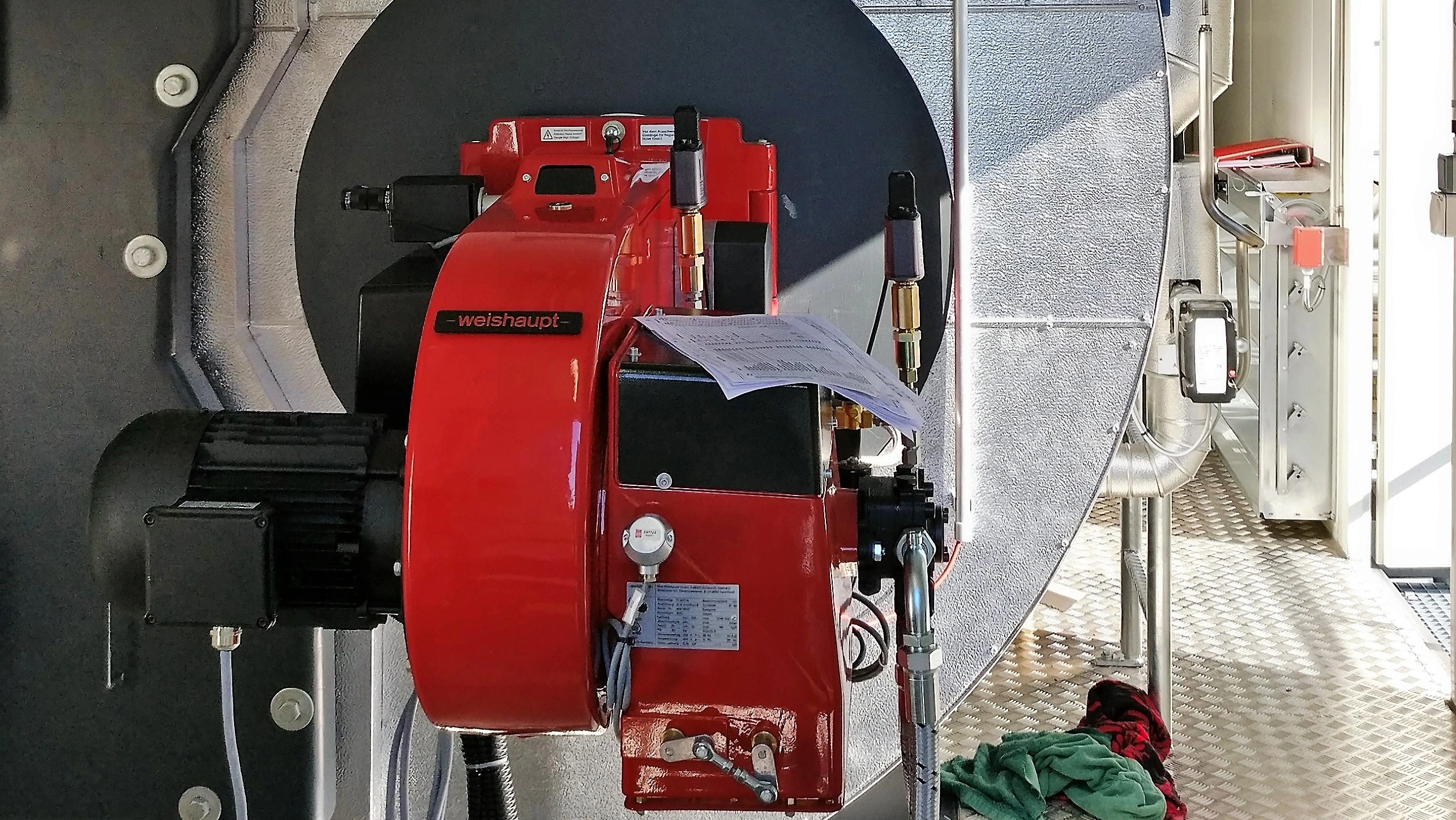

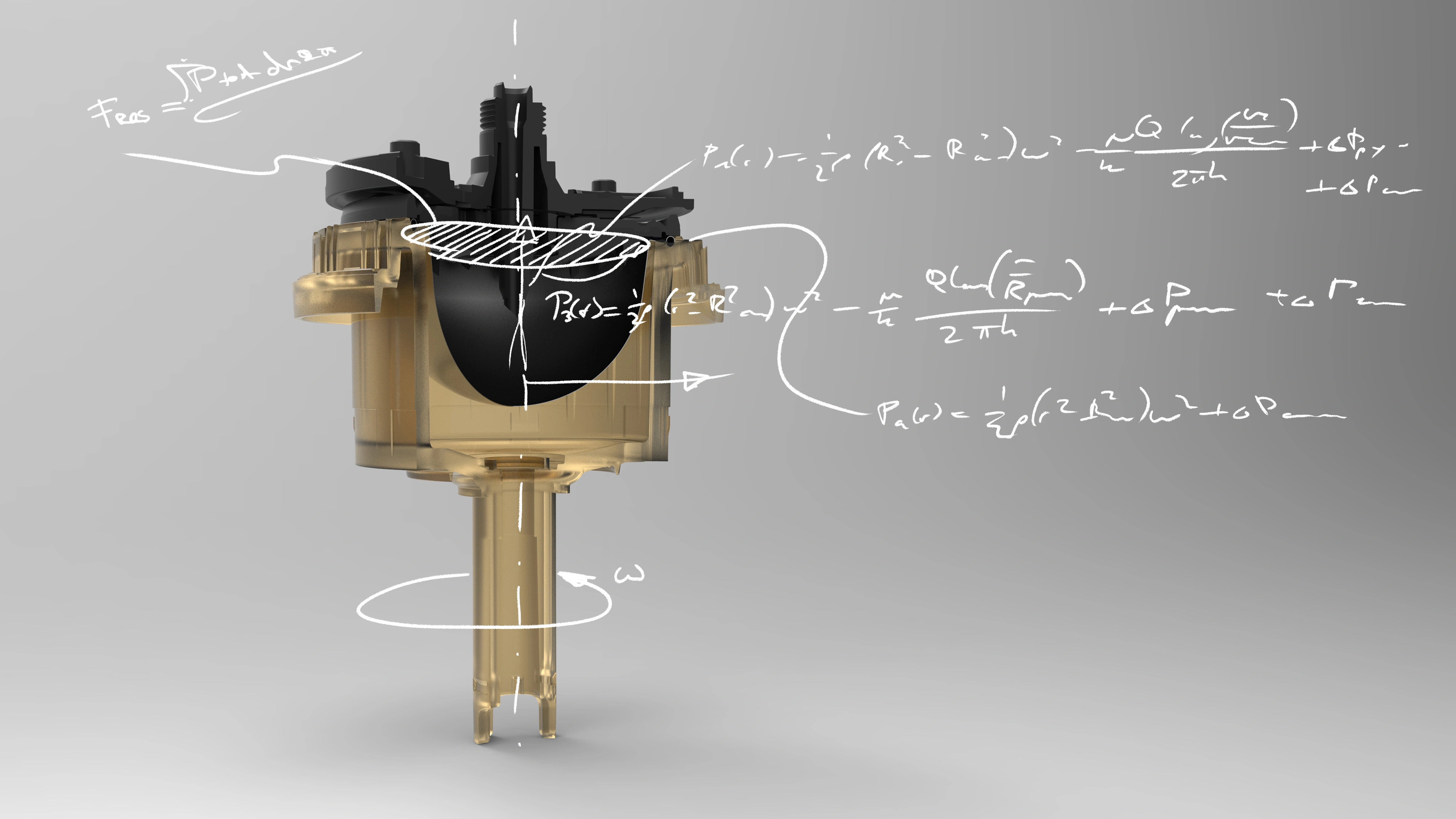

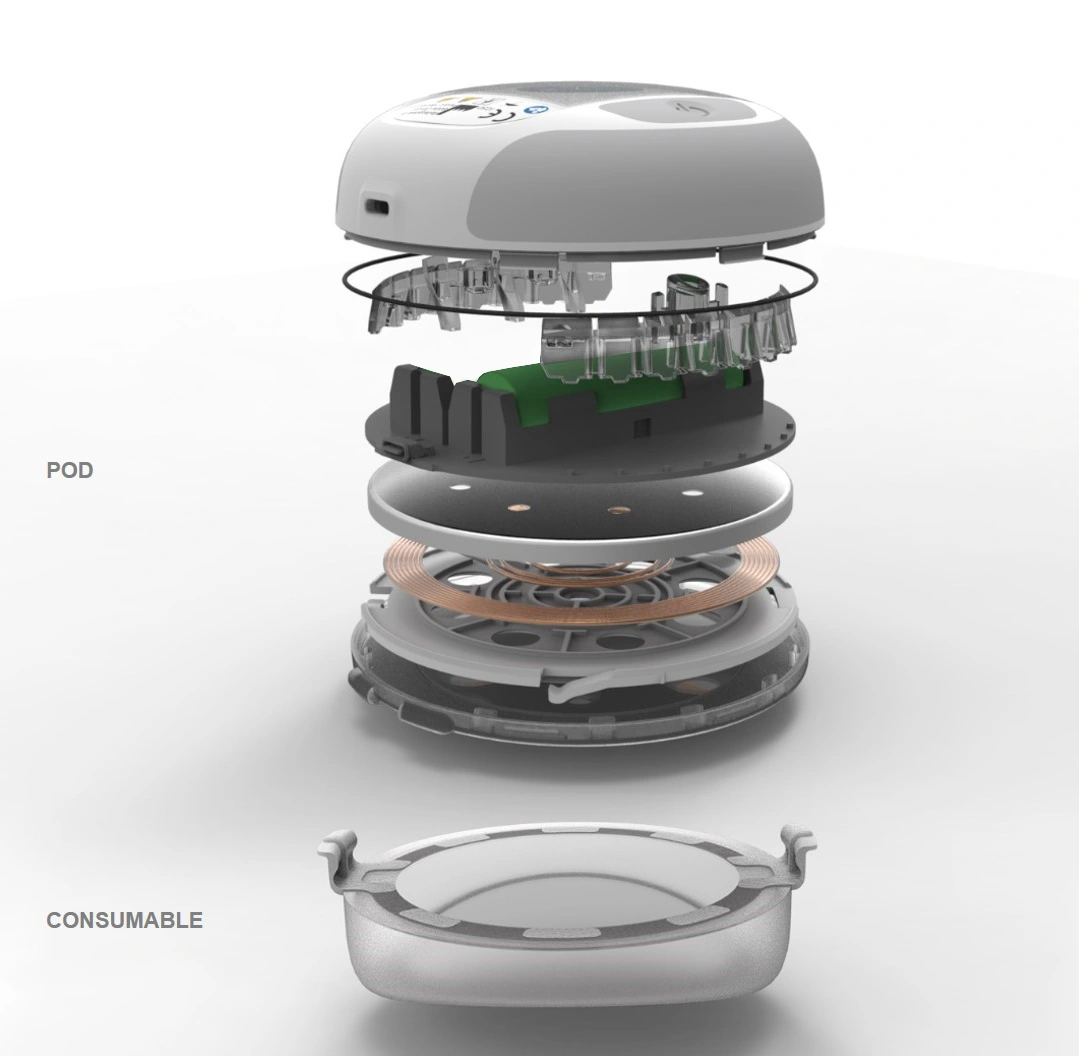

SHL Medical AG is a leading global provider of solutions for the development and production of advanced drug delivery devices such as autoinjectors, pen injectors and advanced inhalation systems in the pharmaceutical and biotech sectors. Due to the strong increase in demand for autoinjectors, the existing production capacities should be expanded and new sites established.

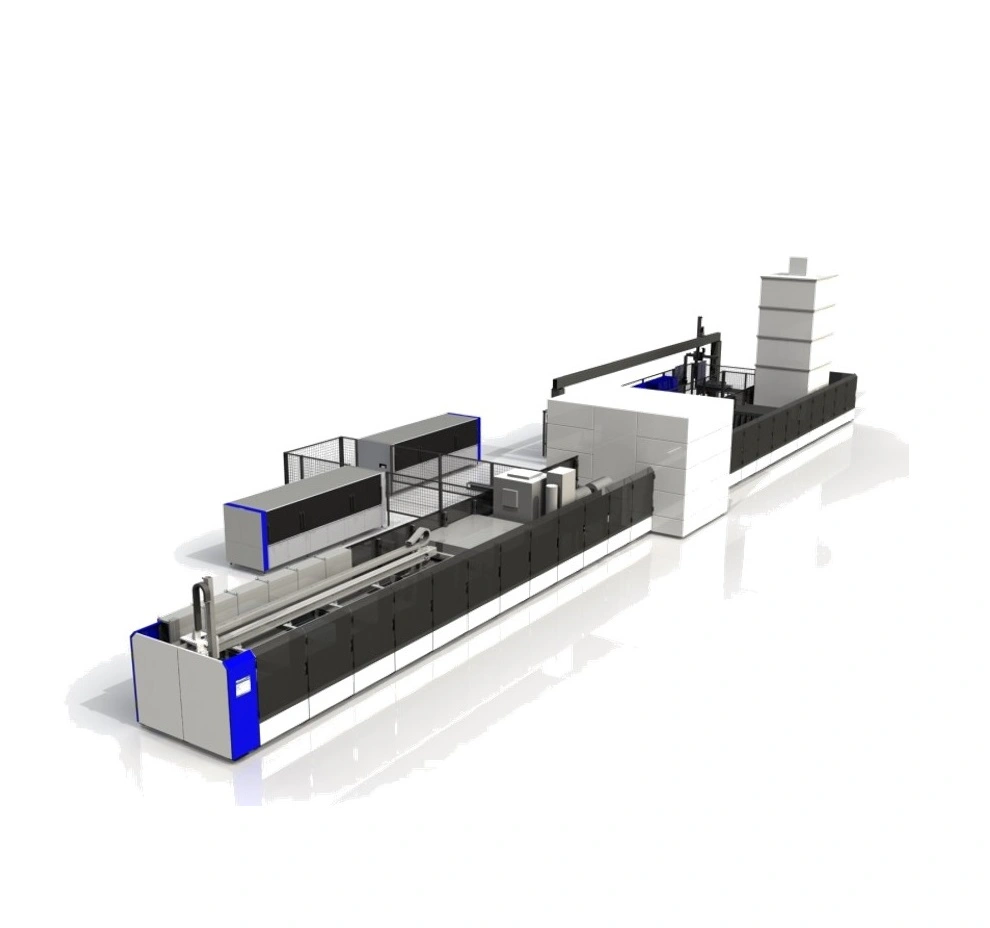

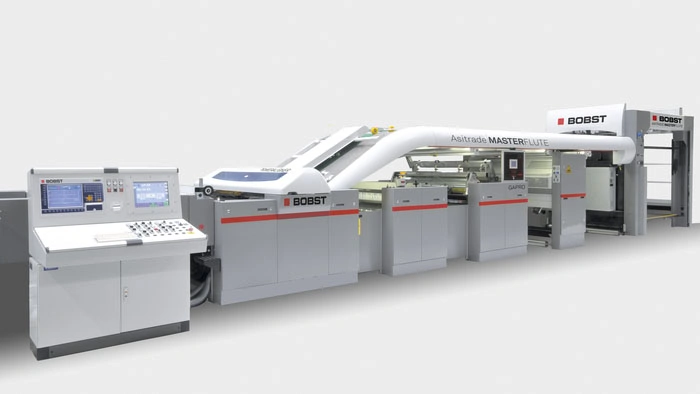

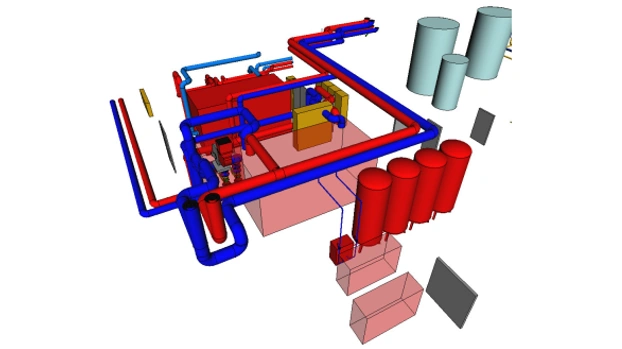

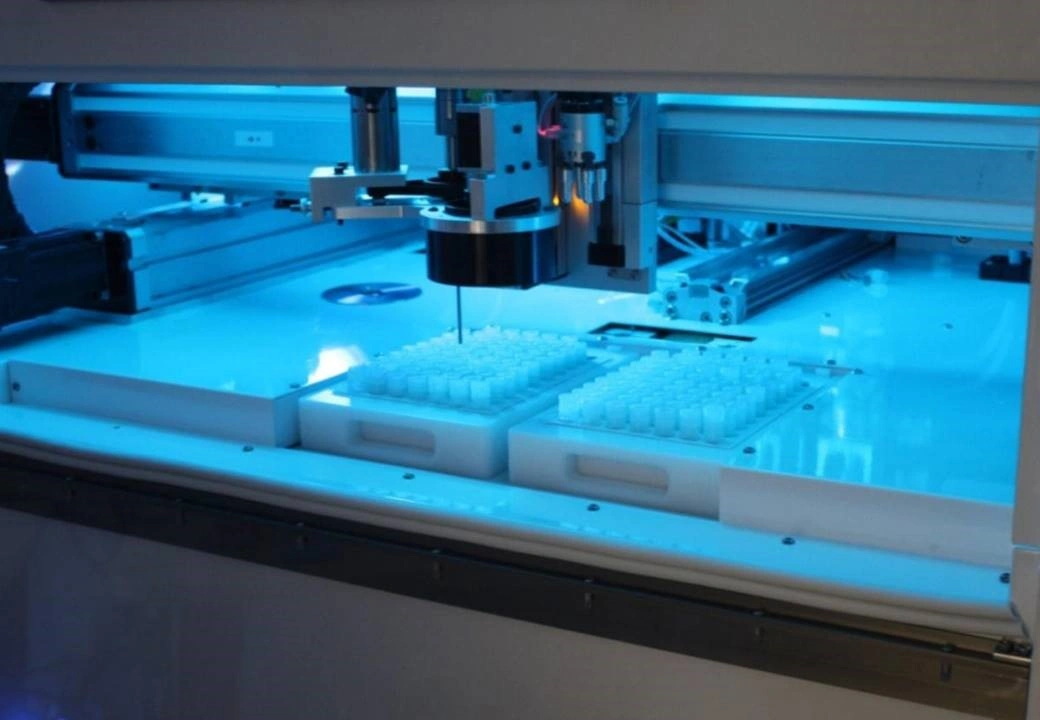

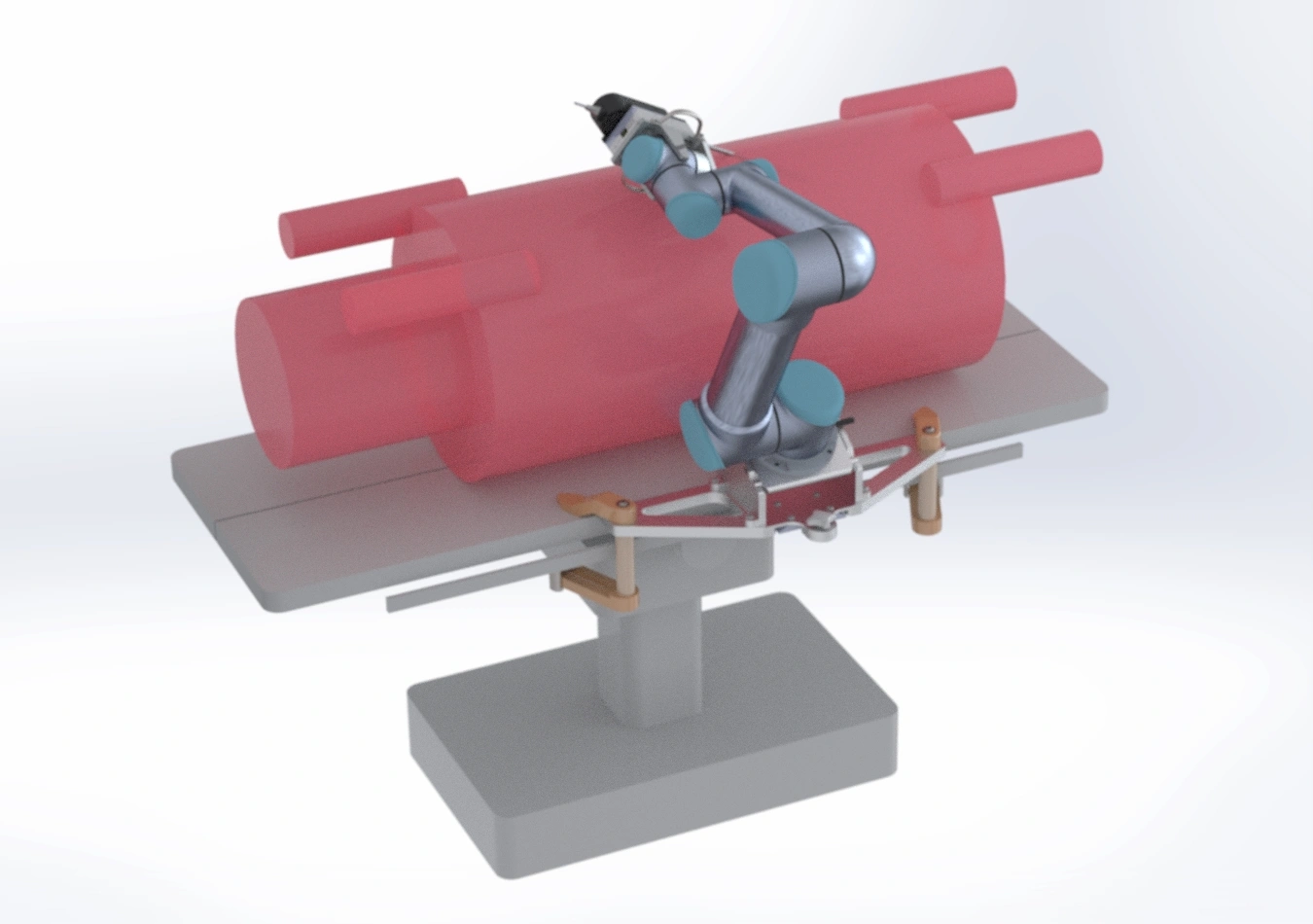

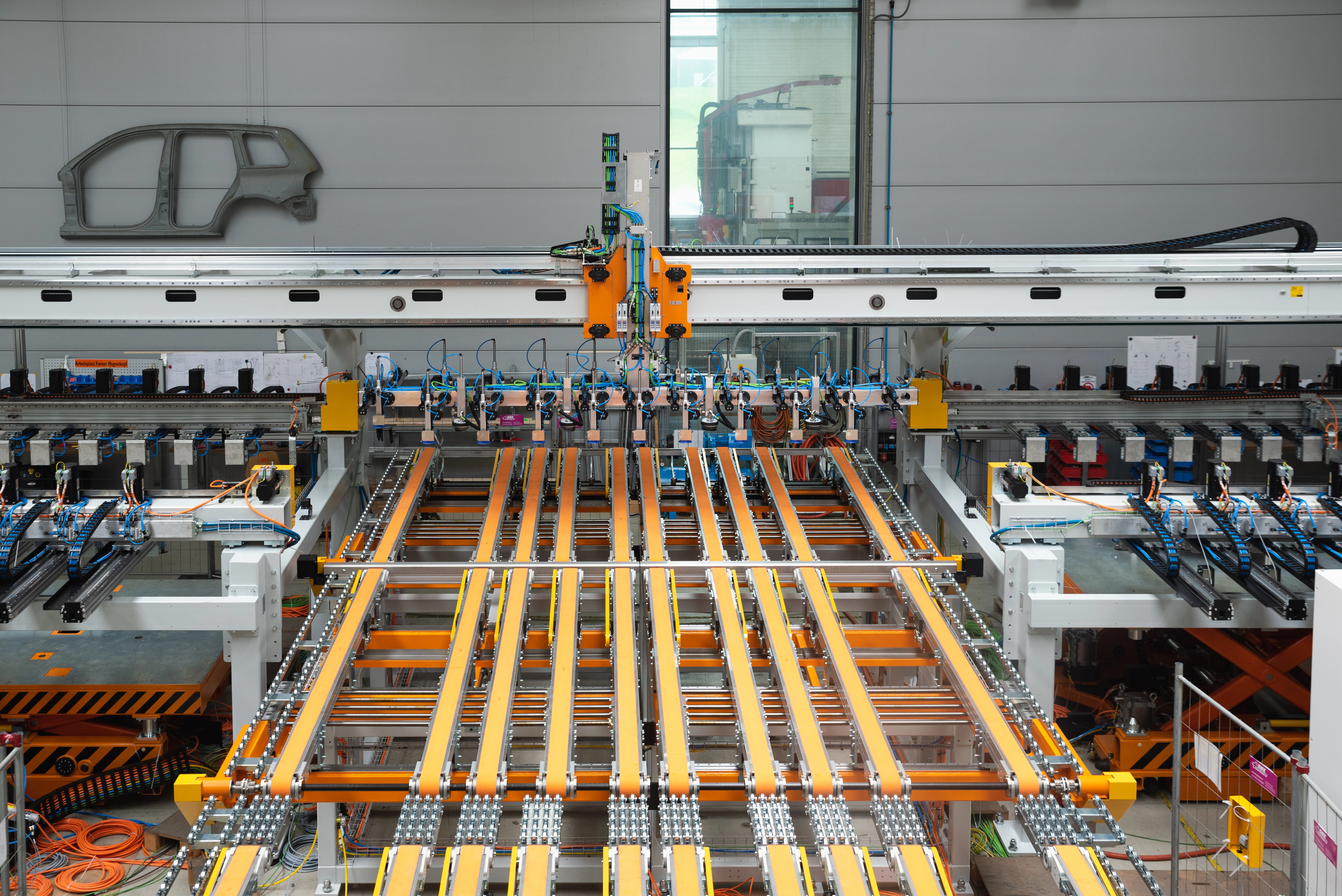

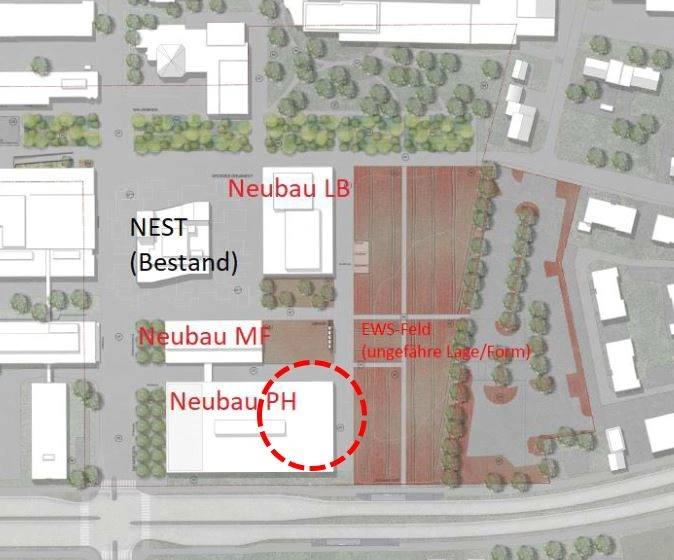

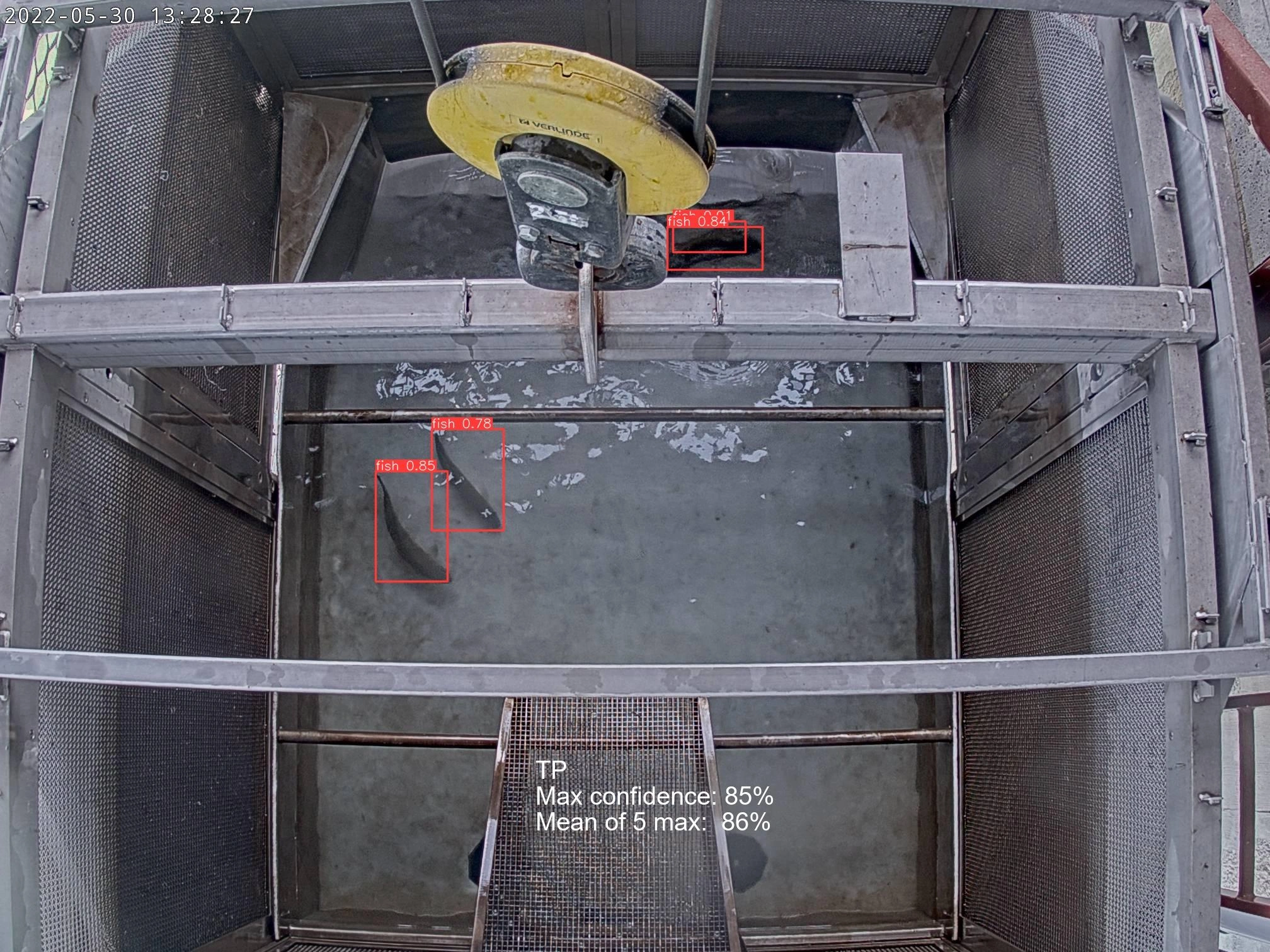

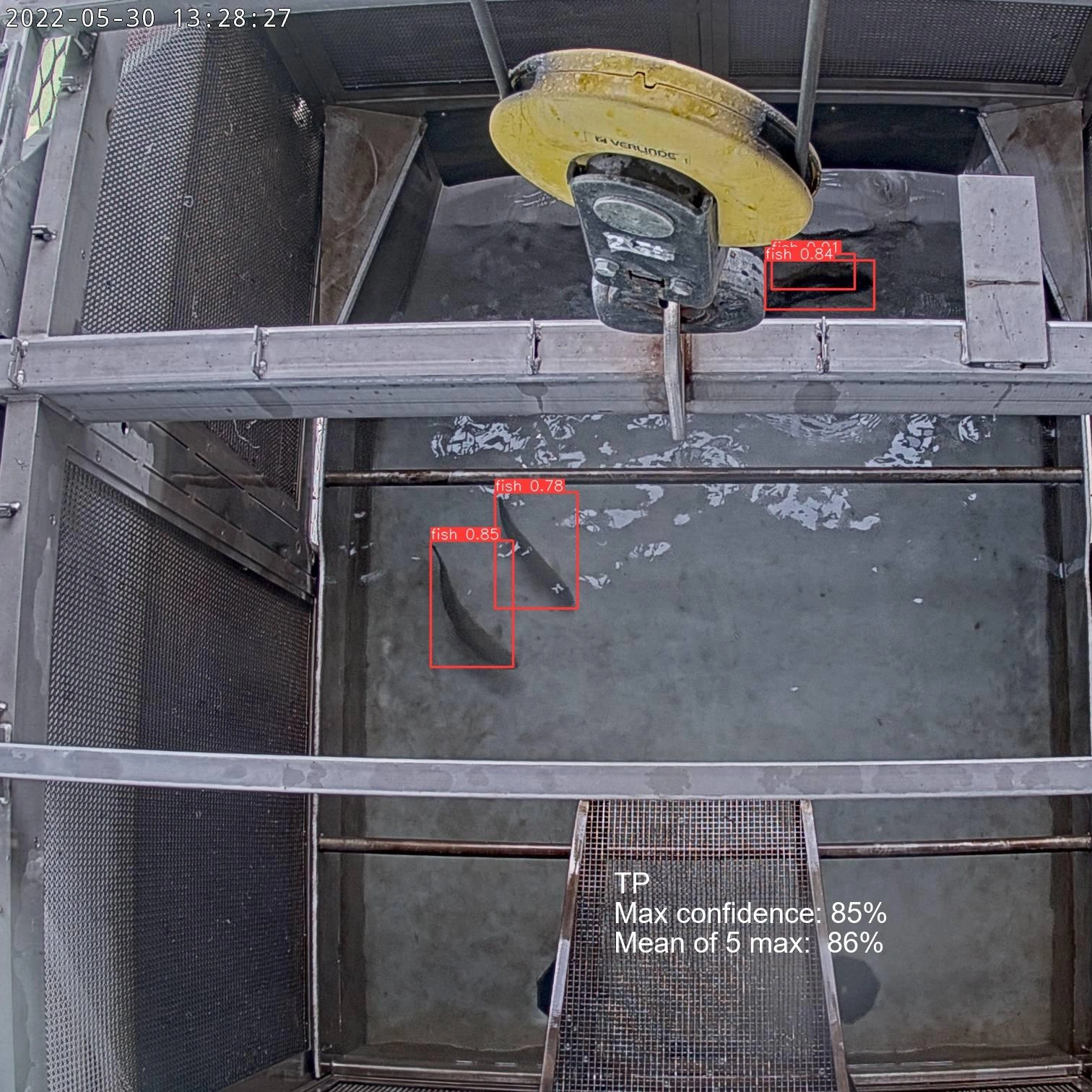

Helbling supported and accompanied SHL Medical as part of its global expansion strategy in various areas at different levels in a complex and highly regulated environment. In the area of factory planning, the maximum capacity of the existing sites was explored in relation to various optimization measures and new highly integrated and automated production facilities were designed and planned.

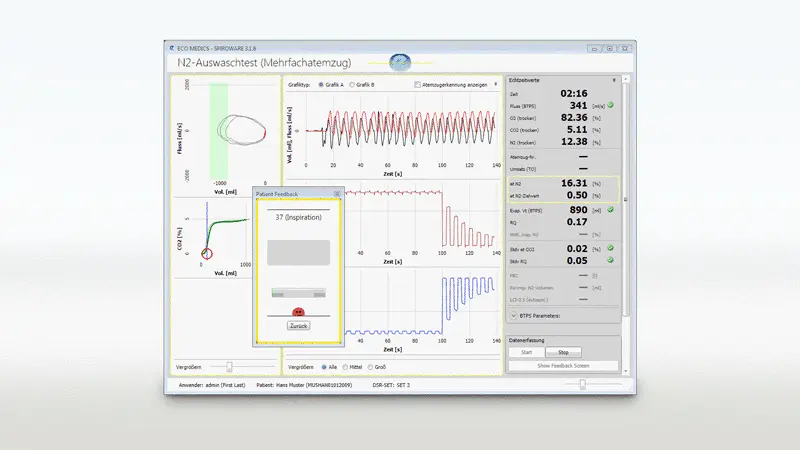

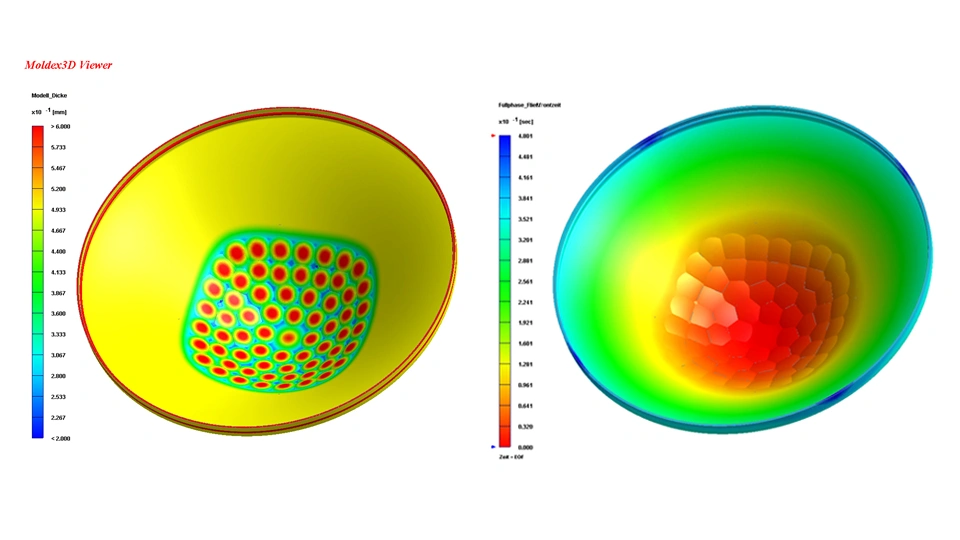

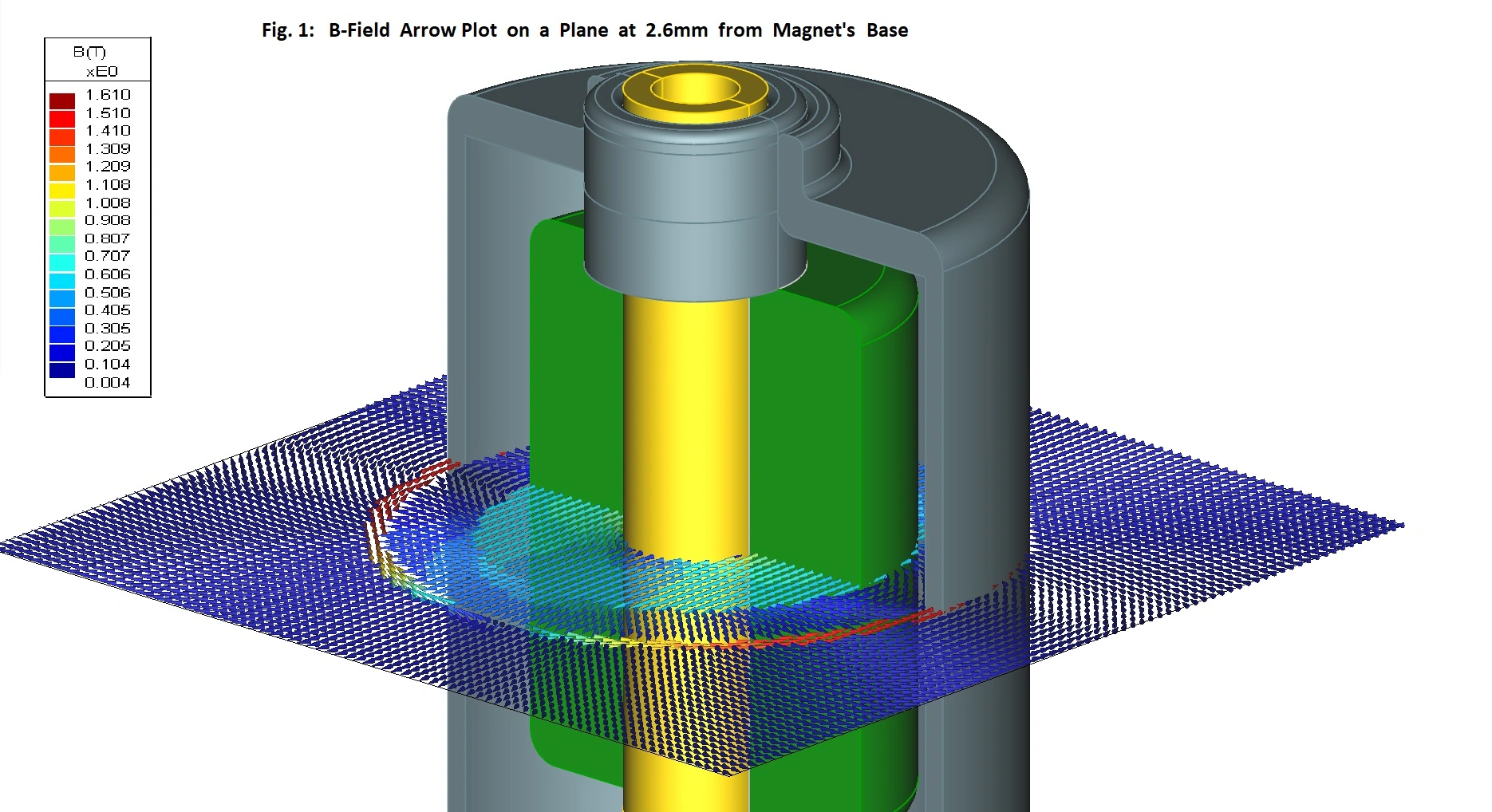

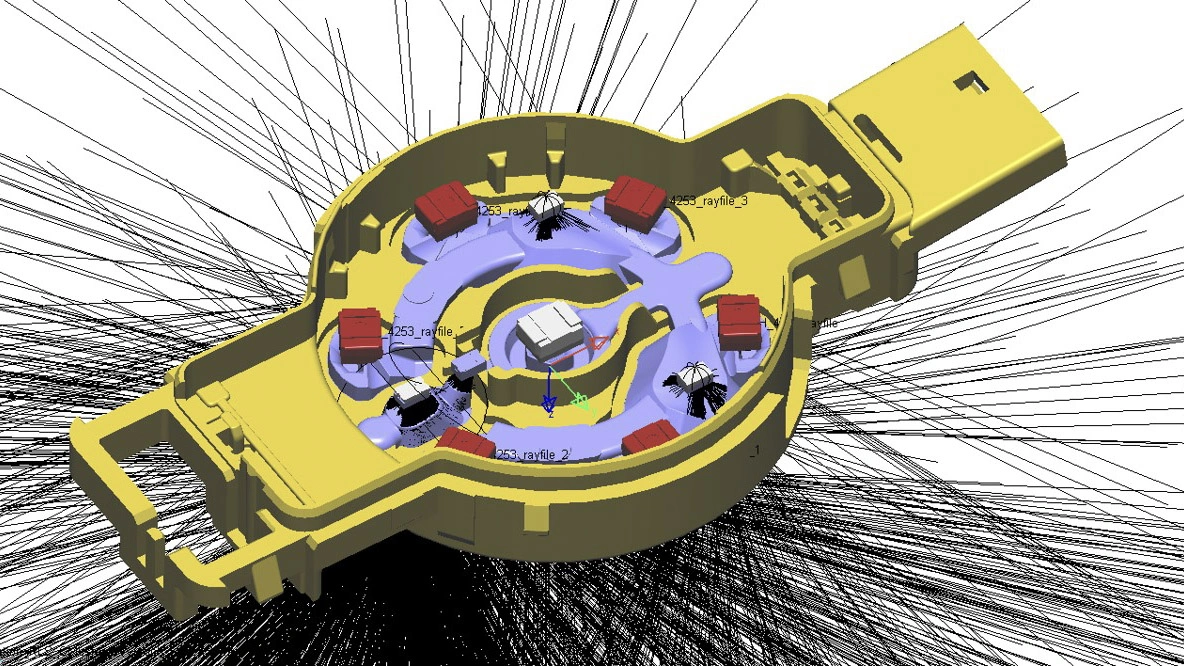

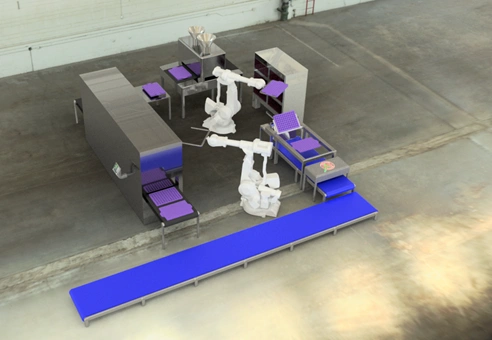

A generic simulation platform was used to virtually validate and evaluate the developed scenarios and concepts at an early stage.

Key Figures

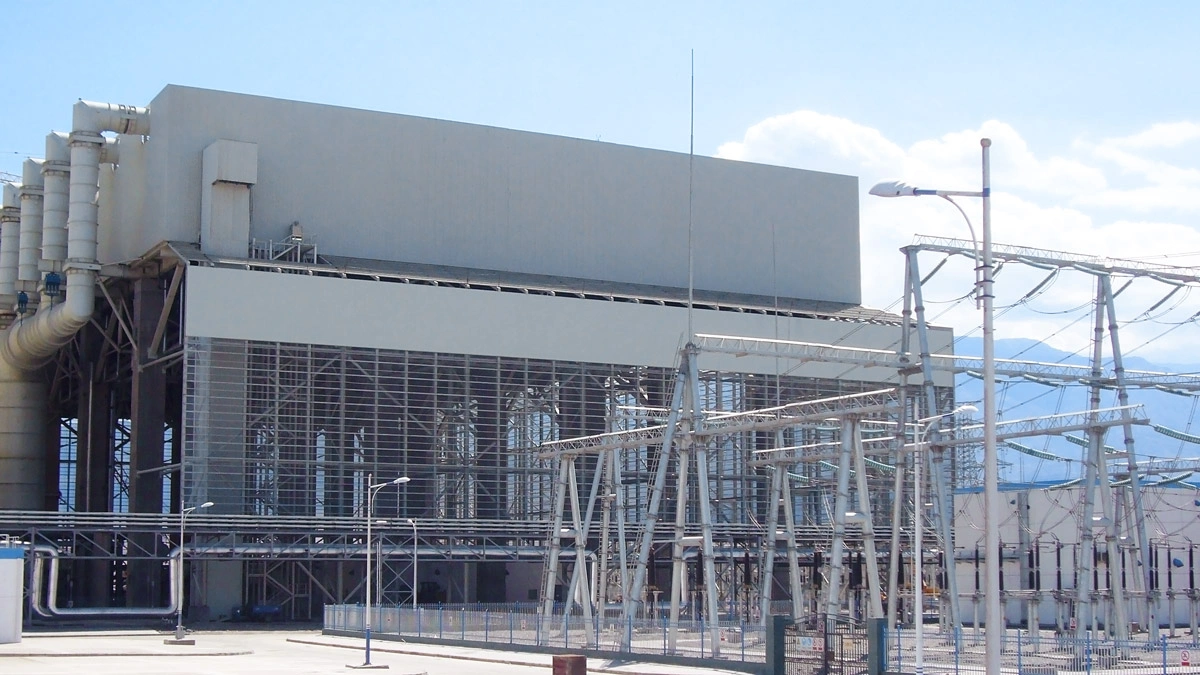

- Locations: Europe, USA and Asia

- Optimized plant layouts in terms of material flow, area productivity and flexibility

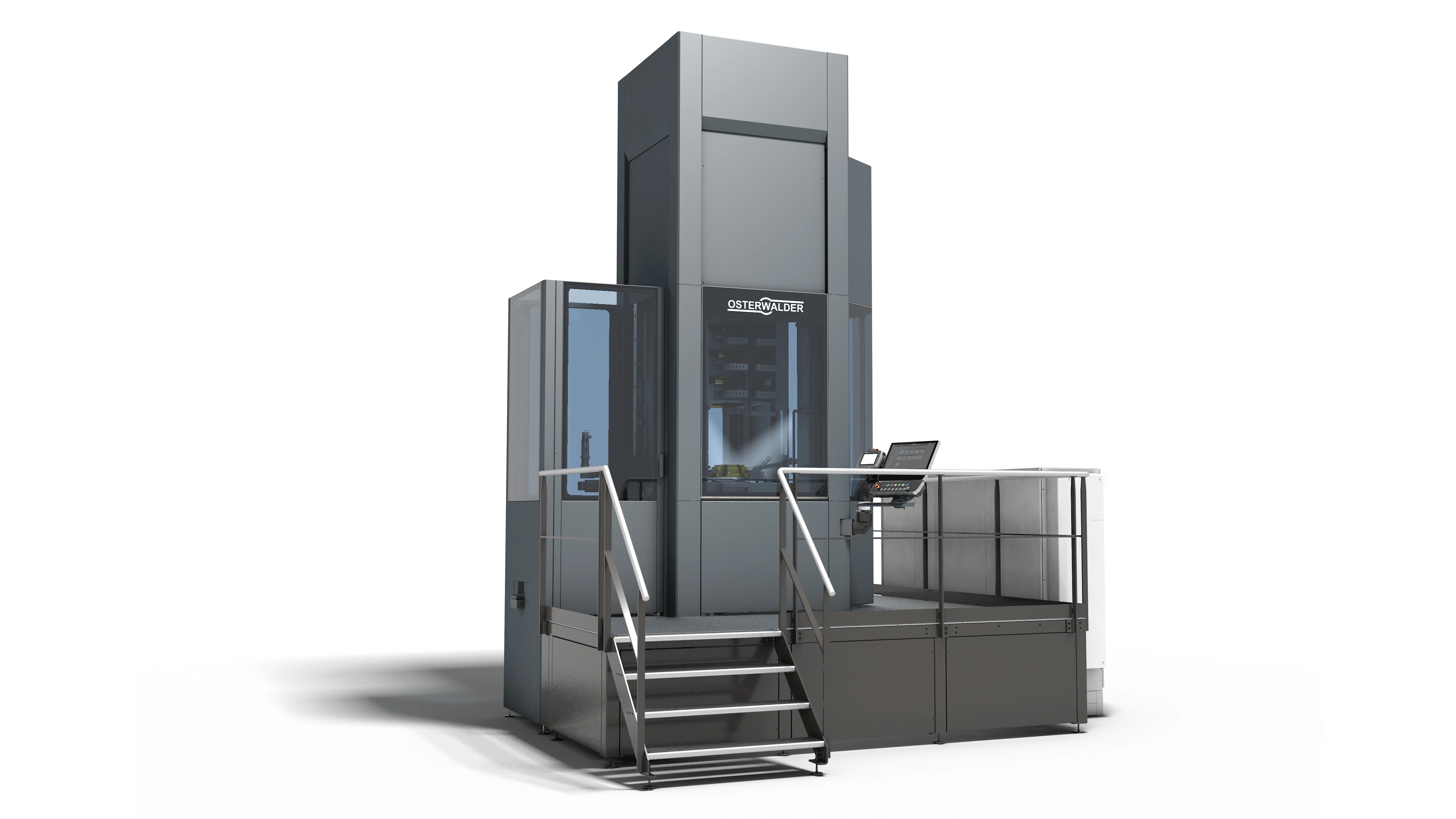

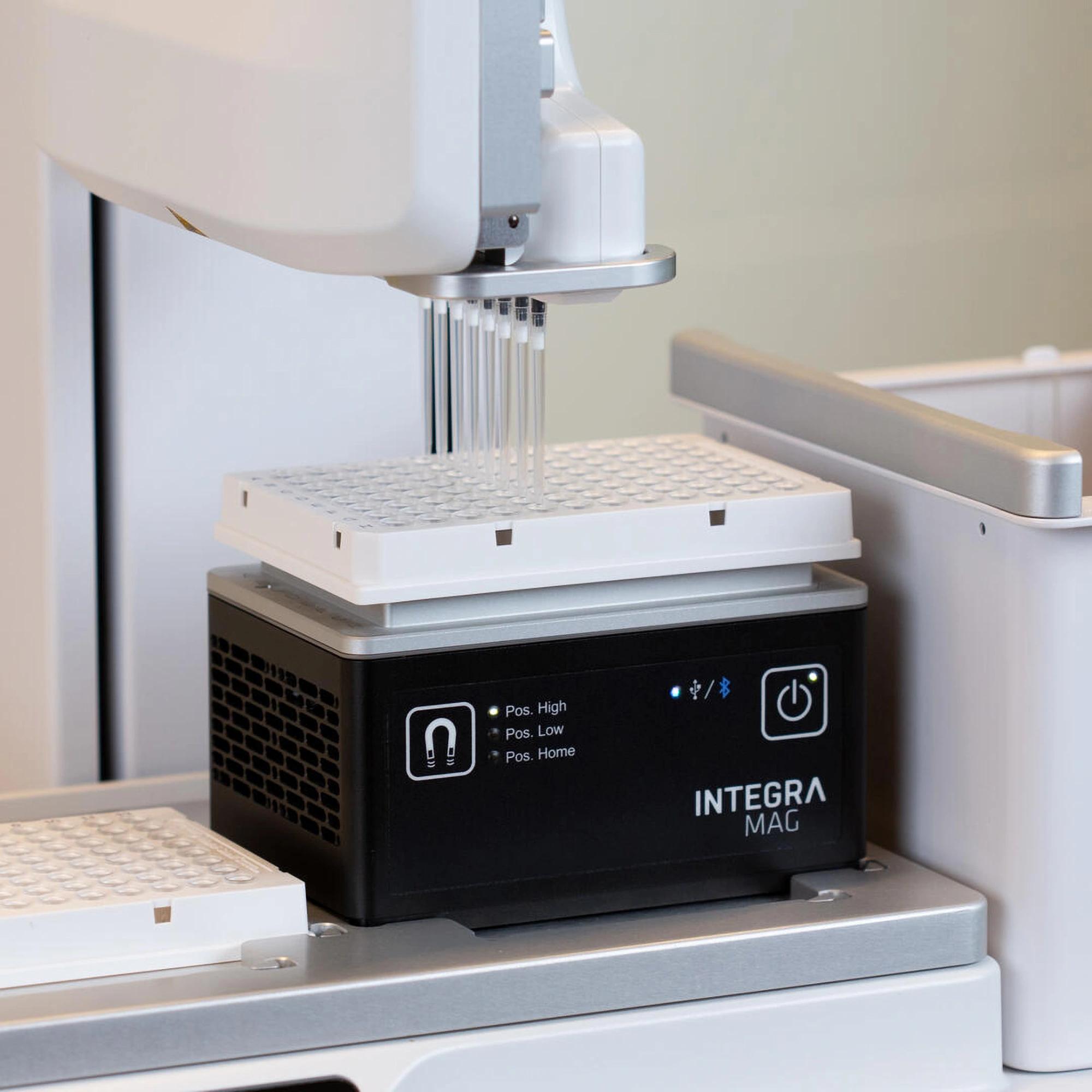

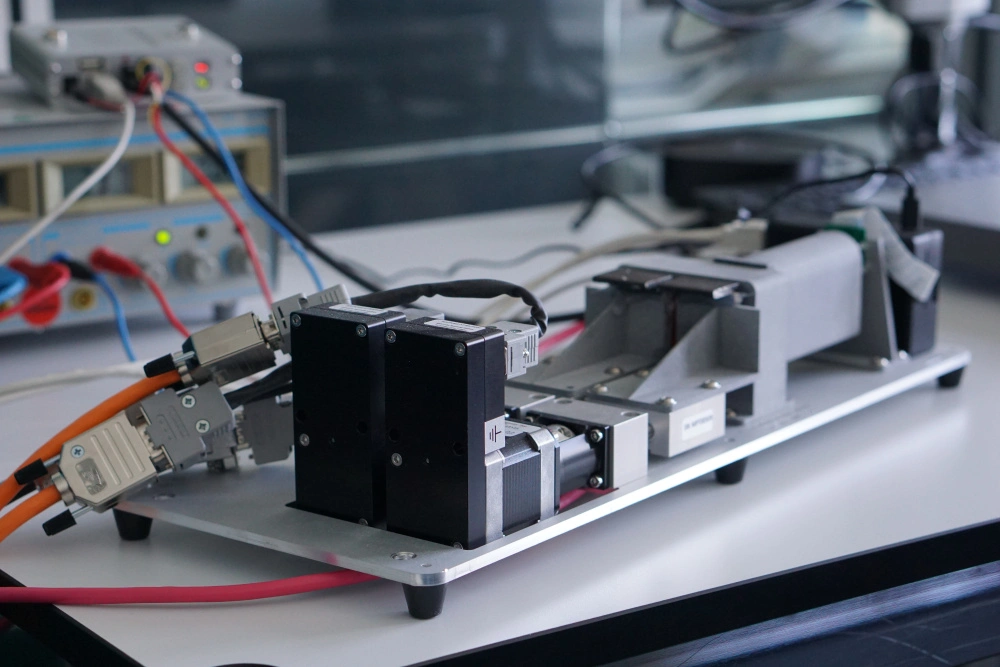

- High degree of automation

- End-to-end digitalization

- Helbling project duration (to date):

2020-2024 (cross-project)

Our Contribution

- Search for possible production sites according to the requirements profile

- Evaluation of possible locations from an operational point of view

- Definition of requirements and judging of an architectural competition from an operational perspective

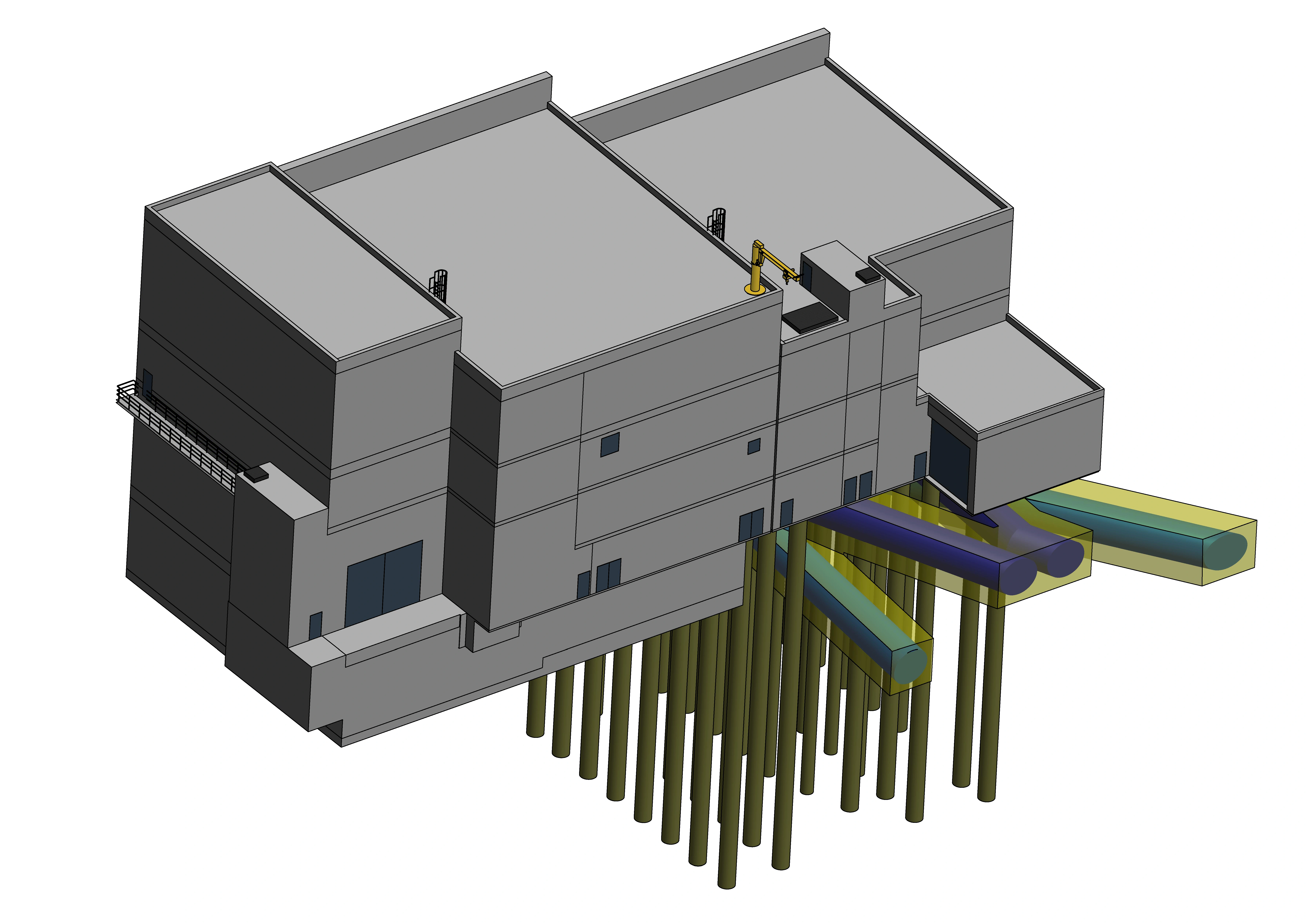

- Concept planning for several new factories

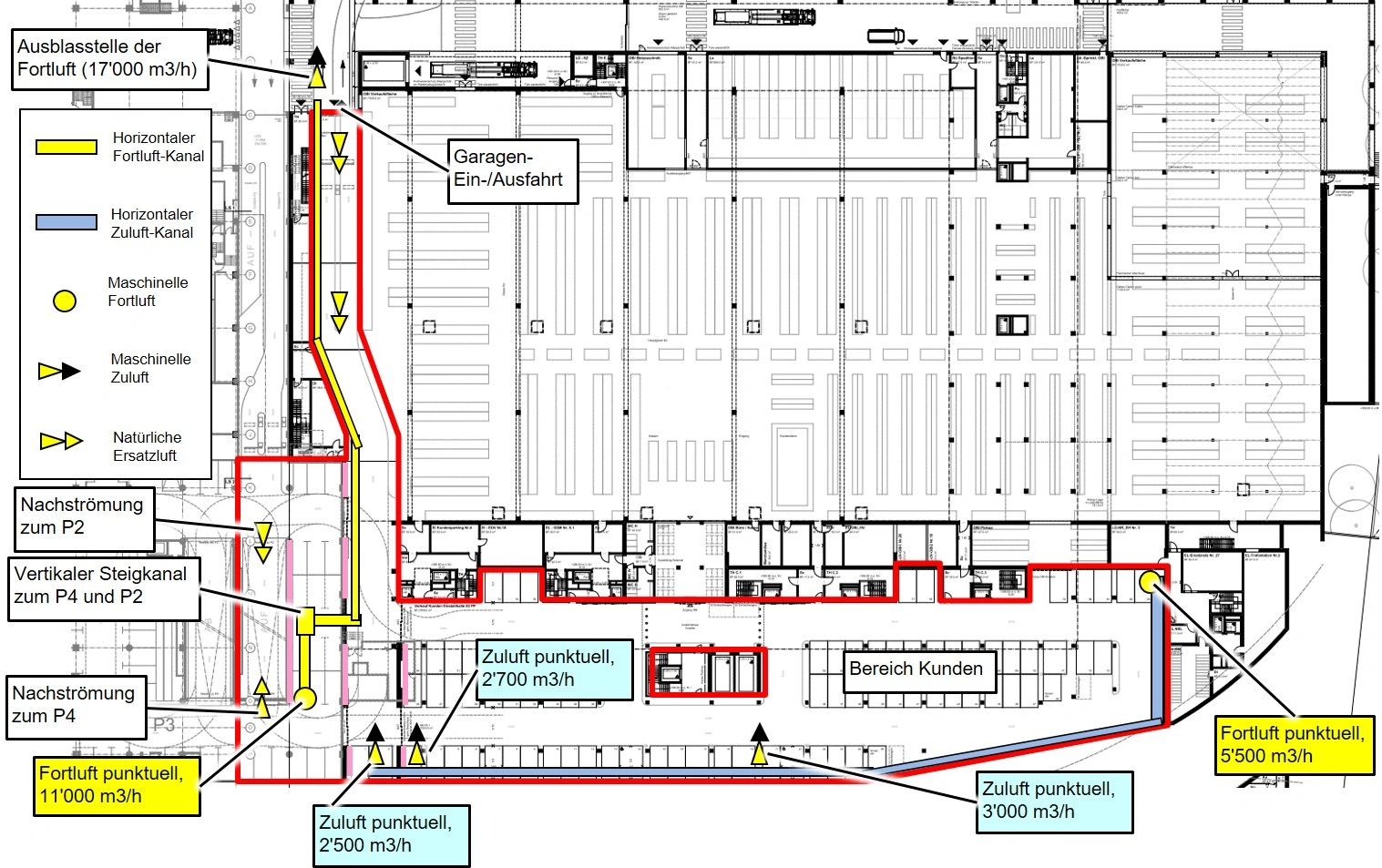

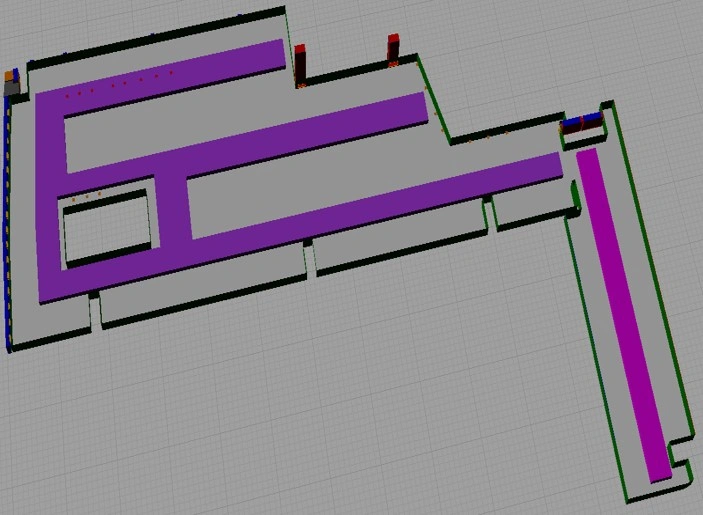

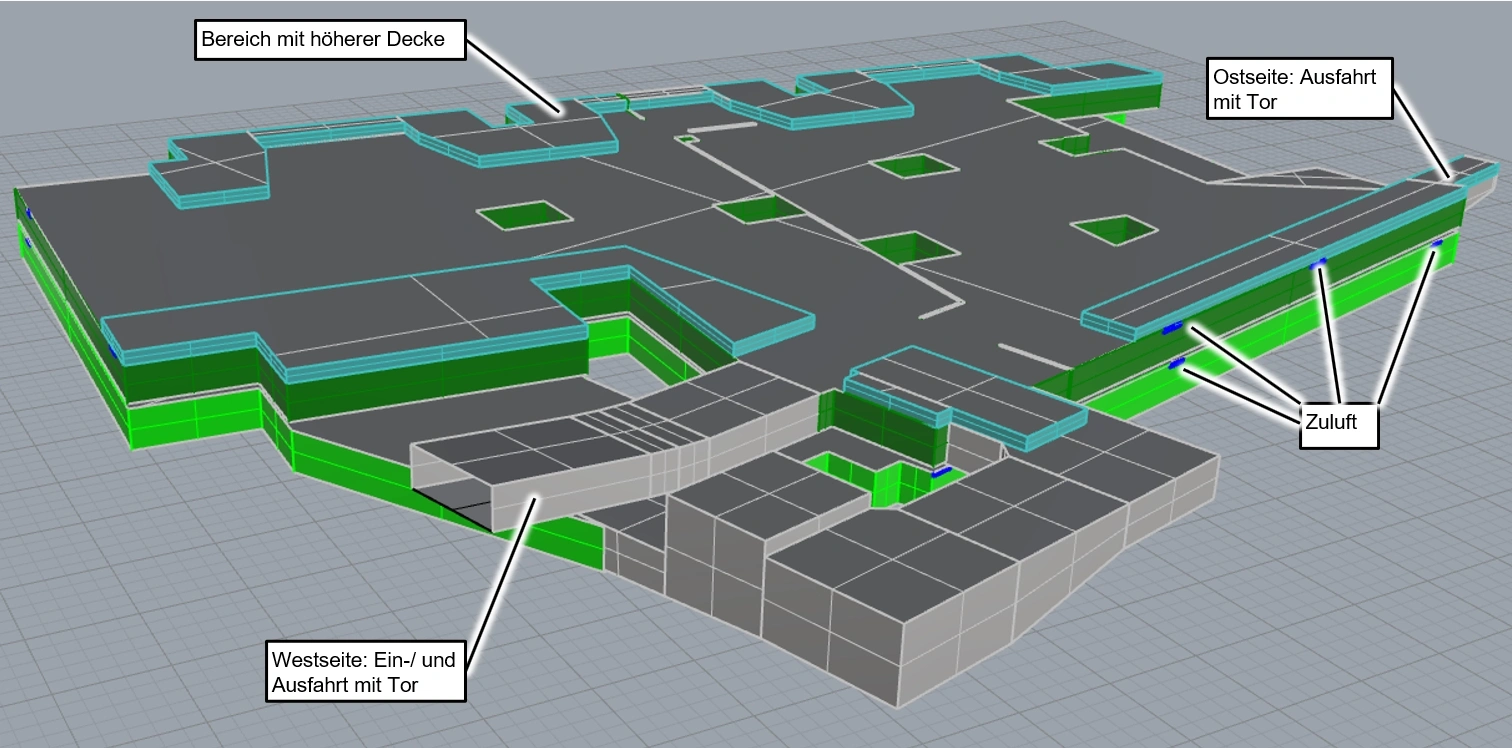

- Detailed planning of operational layouts for production, maintenance and logistics areas

- Coordination activities with equipment suppliers and collaboration in the development of intralogistics solutions

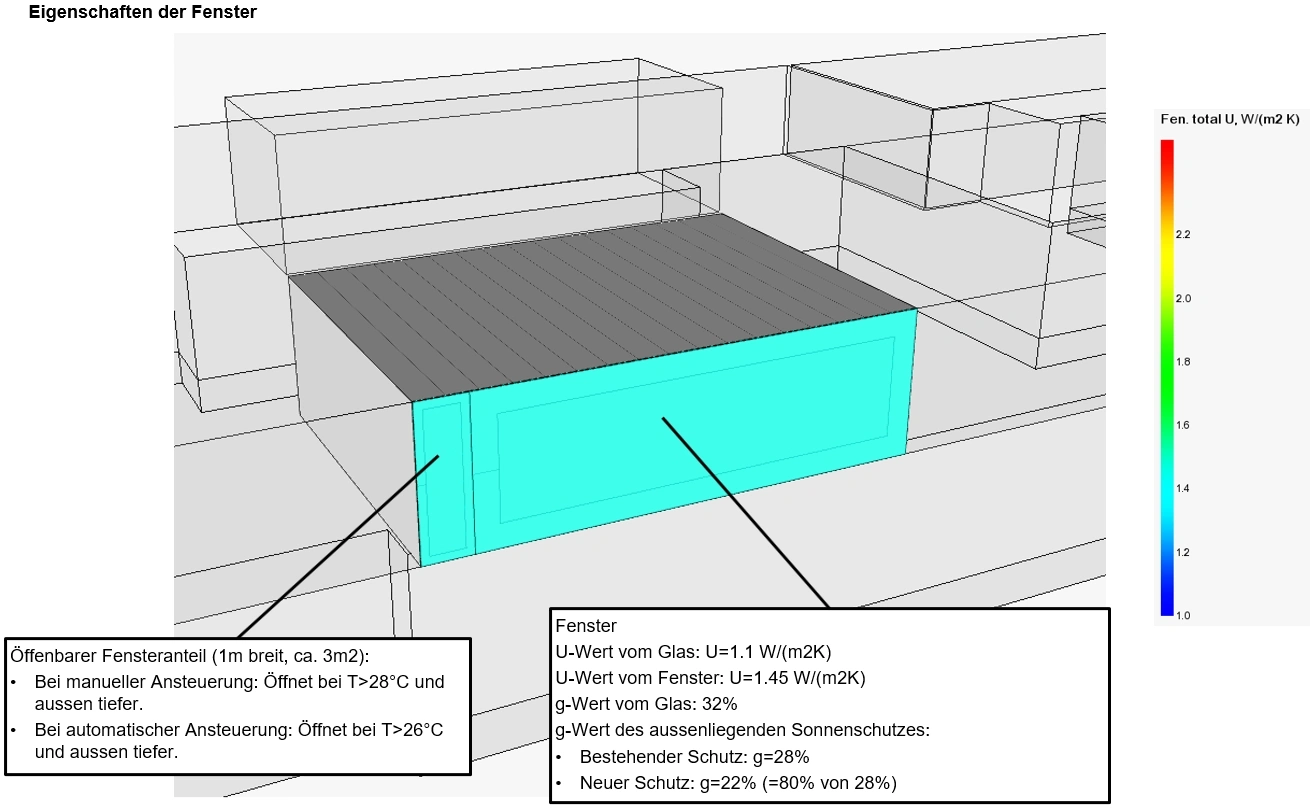

- Coordination activities with on-site technical planners (including using BIM)

- Development of a customer-specific generic simulation platform to support the planning and optimization of new and existing locations

- Planning of end-to-end digitization (including the introduction of MES and EWM systems)

Outcome

- Solid and sophisticated operational layouts of two new production sites (realization in progress)

- Generic simulation platform for the optimization and validation of scenarios and concepts for further use in future projects

- End-to-end digitization

Contact

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

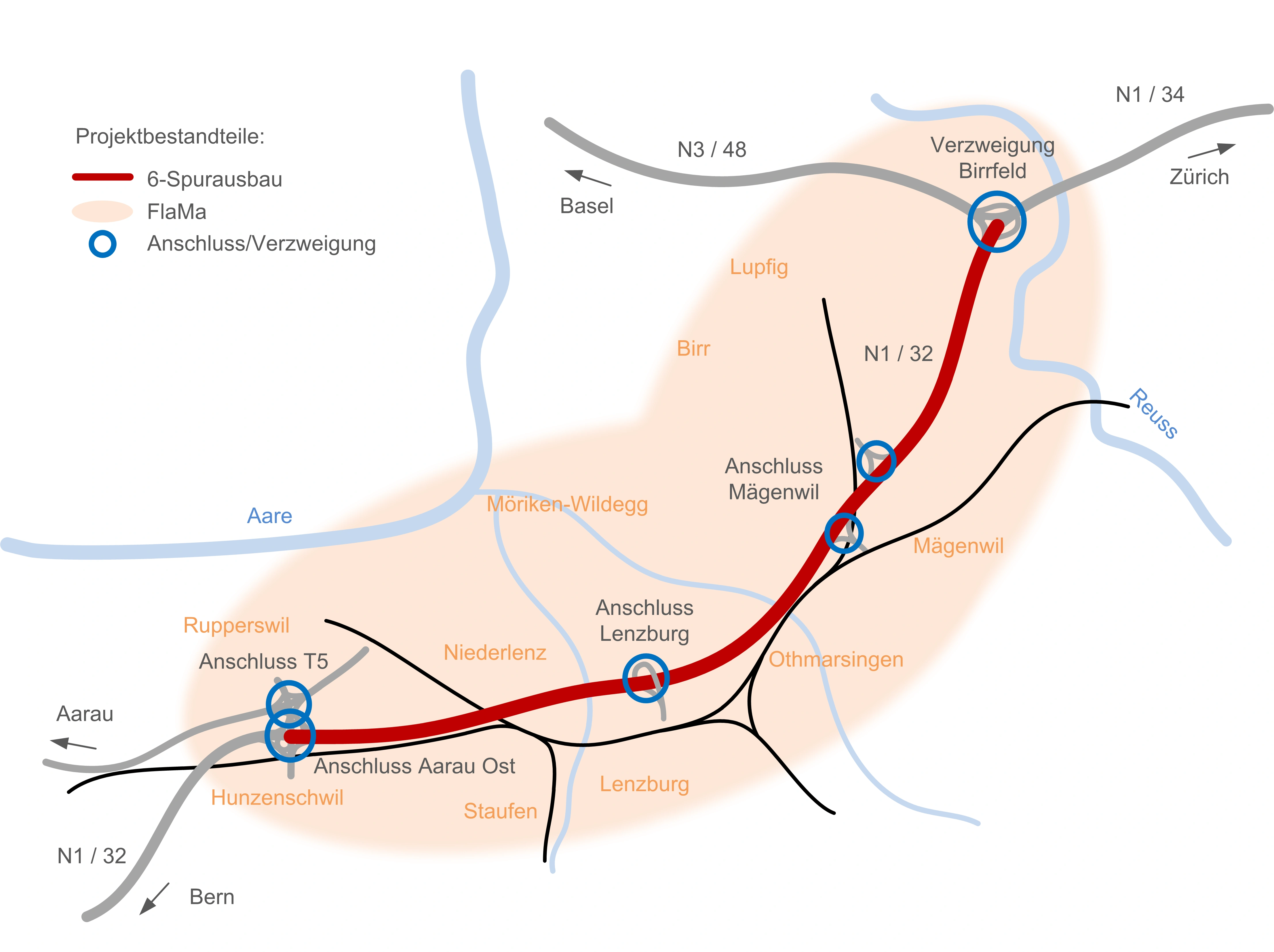

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: